A powder porous fireproof and heat-insulating coating for aluminum alloy and its preparation method

A heat-insulating coating and aluminum alloy technology, applied in coatings, devices for coating liquid on the surface, etc., can solve problems such as unsatisfactory fire-proof and heat-insulation effects, high production costs, and non-compliance with environmental protection requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] Step 1. Weigh the following components according to mass percentage,

[0032] Bauxite powder 75%, EPS powder 0.3%, binder polytetrafluoroethylene 12%, binder copper phosphate 12.7%, the total is 100%;

[0033] Step 2, mixing the bauxite powder, EPS powder, polytetrafluoroethylene, and copper phosphate weighed in step 1 in proportion to obtain mixture A;

[0034] Step 3. Put the mixture A obtained in step 2 on a planetary ball mill for high-speed dispersion mixing and stirring for 10 hours to obtain powder fireproof and heat-insulating coating B;

[0035] Step 4. Use a spray gun to spray the powder fire-proof and heat-insulating coating B obtained in step 3 on the surface of the pretreated aluminum alloy, spray twice, and dry at 300°C for 40 minutes to obtain a powder porous fire-proof and heat-insulating coating, and finally Apply fire retardant coating with matching topcoat.

Embodiment 2

[0037] Step 1. Weigh the following components according to mass percentage,

[0038] Bauxite powder 82%, EPS powder 0.5%, binder polytetrafluoroethylene 8%, binder copper phosphate 9.5%, the total is 100%;

[0039] Step 2, mixing the bauxite powder, EPS powder, polytetrafluoroethylene, and copper phosphate weighed in step 1 in proportion to obtain mixture A;

[0040] Step 3. Put the mixture A obtained in step 2 on a planetary ball mill for high-speed dispersion mixing and stirring for 8 hours to obtain powder fireproof and heat-insulating coating B;

[0041] Step 4. Use a spray gun to spray the powder fire-proof and heat-insulating coating B obtained in step 3 on the surface of the pretreated aluminum alloy, spray twice, and dry at 250°C for 70 minutes to obtain a powder porous fire-proof and heat-insulating coating, and finally Apply fire retardant coating with matching topcoat.

Embodiment 3

[0043] Step 1. Weigh the following components according to mass percentage,

[0044] Bauxite powder 88%, EPS powder 0.8%, binder polytetrafluoroethylene 5%, binder copper phosphate 6.2%, the total is 100%;

[0045] Step 2, mixing the bauxite powder, EPS powder, polytetrafluoroethylene, and copper phosphate weighed in step 1 in proportion to obtain mixture A;

[0046] Step 3. Put the mixture A obtained in step 2 on a planetary ball mill for high-speed dispersion mixing and stirring for 5 hours to obtain powder fireproof and heat-insulating coating B;

[0047] Step 4. Use a spray gun to spray the powder fire-proof and heat-insulating coating B obtained in step 3 on the surface of the pretreated aluminum alloy, spray for 3 times, and dry at 200°C for 50 minutes to obtain a powder porous fire-proof and heat-insulating coating. Finally Apply fire retardant coating with matching topcoat.

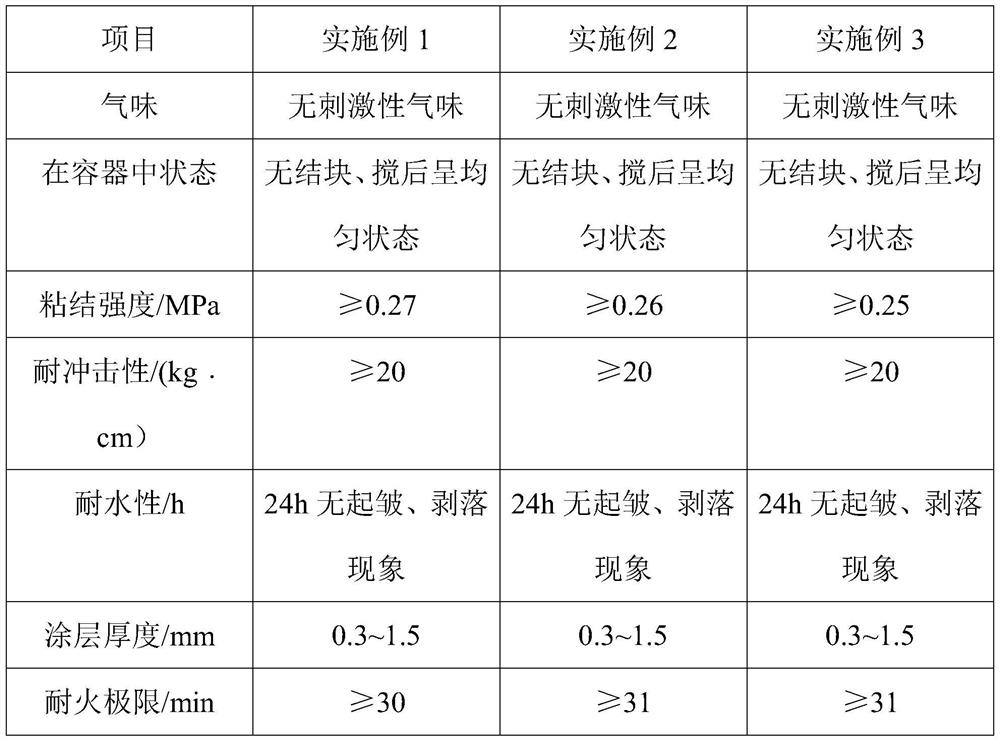

[0048] The specific performance test results of the powder porous fireproof and heat-insulat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com