Halogen-free flame-retardant and anti-static polyethylene material, pipe and preparing method thereof

A flame retardant, antistatic, polyethylene technology, applied in the direction of pipes, rigid pipes, mechanical equipment, etc., can solve the problems of high modification cost, large amount of smoke, poor environmental protection, etc., achieve excellent comprehensive mechanical properties and reduce raw material costs. , the effect of increasing compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0071] The preparation process of the halogen-free flame-retardant antistatic polyethylene pipe is as follows: extrude the halogen-free flame-retardant antistatic polyethylene material in a pipe extruder at 160-200°C. The prepared halogen-free flame-retardant antistatic polyethylene pipe has high flame-retardant efficiency, and can effectively flame-retardant PE when the amount of flame retardant and synergistic flame retardant is small; at the same time, it can reduce the use of expensive conductive carbon black, When the content of conductive carbon black is 3%, it can meet the requirements of antistatic performance in MT 181-88 "Specification for Testing the Safety Performance of Plastic Pipes Used in Underground Coal Mine"; the comprehensive mechanical properties of the material are excellent.

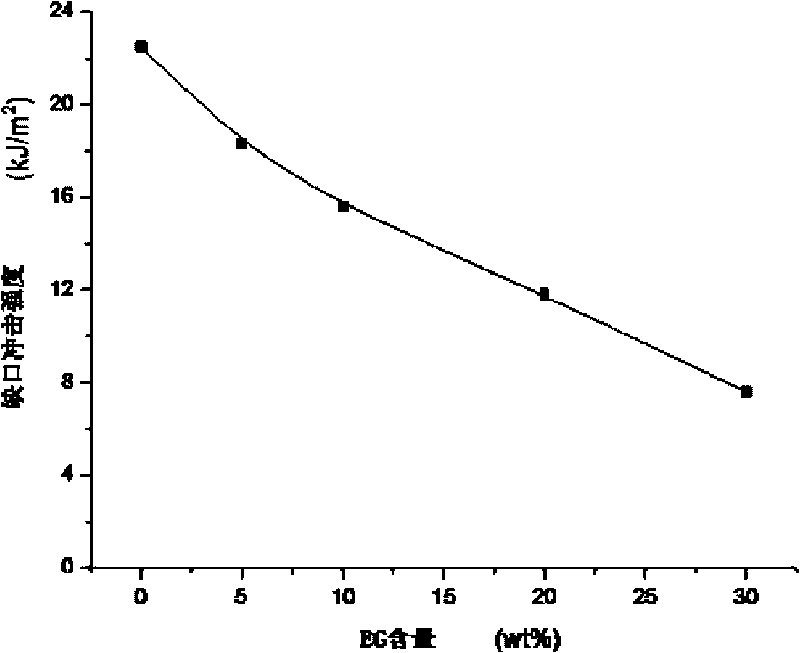

[0072] Although EG modification can improve the flame retardancy and antistatic properties of the material at the same time, after EG is added to PE, the mechanical properties of th...

Embodiment 1

[0088] Example 1 Preparation of halogenated flame retardant antistatic polyethylene pipe of the present invention

[0089] After drying 1 part of high-density polyethylene in an oven at 80°C for 4 hours, and 99 parts of expandable graphite with a particle size of 10 mesh, add it to a high-speed mixer and mix evenly, and grind it in a mechanochemical reactor for 10 times to obtain the average particle size It is 1000 mesh EG / PE ultrafine composite powder.

[0090] After drying 80 parts of PE100 high-density polyethylene in an oven at 80°C for 2 hours, add 20 parts of ultrafine composite powder, 1 part of APP, and 3 parts of conductive carbon black into a high-speed mixer and mix evenly. Melt blending extrusion, granulation, and drying to obtain a halogen-free flame-retardant antistatic polyethylene material. The tensile strength of the material is 22MPa, the notched impact strength is 20kJ / m2, the elongation at break is 350%, and the oxygen index is 30. , UL-94 reaches V0 leve...

Embodiment 2

[0092] Example 2 Preparation of halogen-free flame-retardant antistatic polyethylene pipe of the present invention

[0093] Dry 50 parts of low-density polyethylene in an oven at 80°C for 4 hours, add 50 parts of expandable graphite with a particle size of 200 mesh, mix them evenly in a high-speed mixer, and grind 30 times in a mechanochemical reactor to obtain the average particle size It is 3000 mesh EG / PE ultrafine composite powder.

[0094] After drying 90 parts of PE80 grade medium density polyethylene in an oven at 80°C for 2 hours, add 10 parts of ultrafine composite powder, 10 parts of red phosphorus, 10 parts of PER, and 4 parts of conductive carbon black into a high-speed mixer and mix evenly. Melt blending, extrusion, granulation and drying at a temperature of 180°C to obtain a halogen-free flame-retardant antistatic polyethylene material with a tensile strength of 18MPa, a notched impact strength of 18kJ / m2 and an elongation at break of 400%. , the oxygen index is...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Notched impact strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com