Method for modifying surface of fibrous material

A fiber material and surface modification technology, applied in carbon fiber, fiber treatment, textiles and papermaking, etc., can solve not many problems, achieve the effects of no pollution, low requirements for production equipment, and improved composite performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

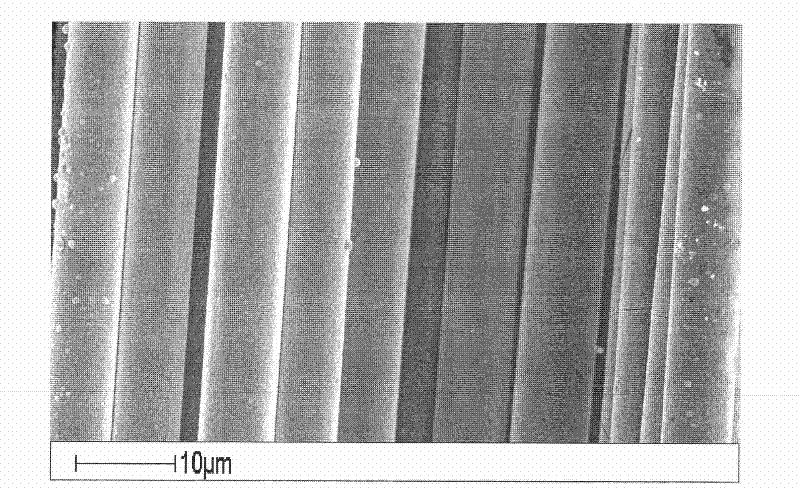

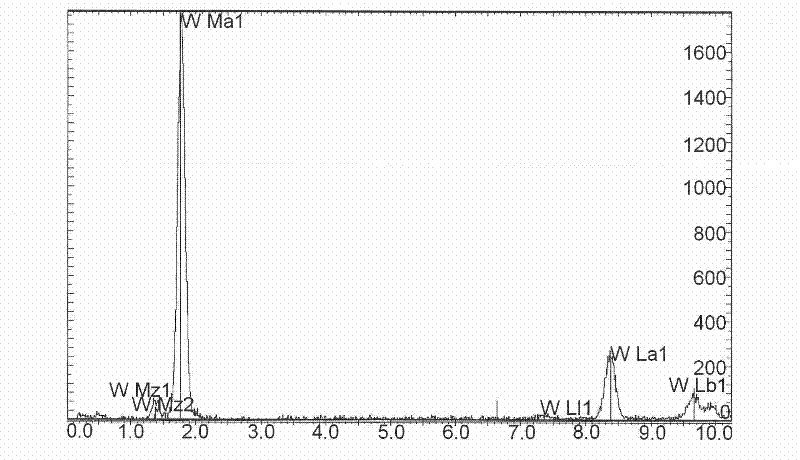

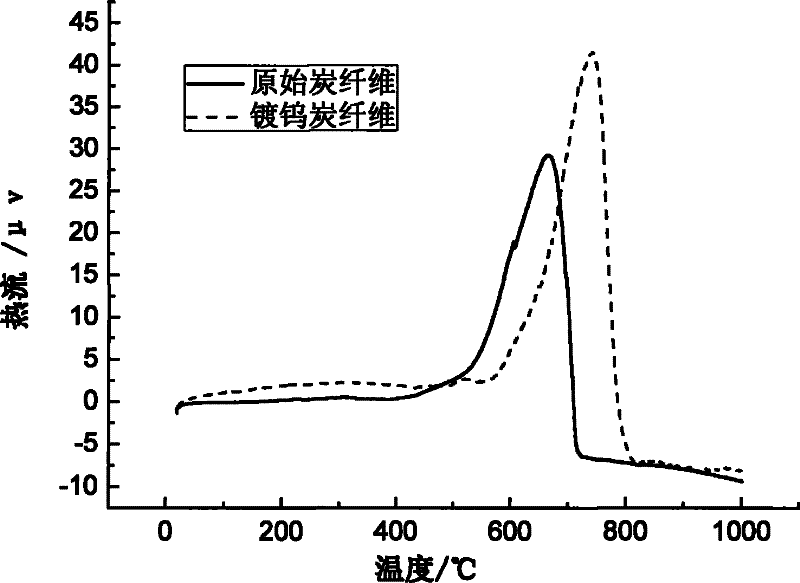

[0025] Carbon fiber (6.5 μm in diameter) is selected as the fiber material, and tungsten hexacarbonyl is selected as the metal carbonyl compound. Burn the carbon fiber at 360°C±10°C for 10 minutes, then soak it in 20% nitric acid solution for 15 minutes, wash it with deionized water and dry it; then place the pretreated carbon fiber in the deposition reaction chamber The raw material of tungsten hexacarbonyl is kept at a constant temperature of 120°C. Nitrogen is used as the carrier gas and diluent gas. The concentration of tungsten hexacarbonyl gas entering the deposition chamber is controlled to be about 1% (volume percentage). The deposition reaction occurs at 550°C for 15 minutes. The surface of the fiber is coated with a tungsten film with a thickness close to 100nm. Scanning electron microscope photo of tungsten-coated carbon fiber figure 1 ; The results of energy spectrum analysis of the coating are as follows figure 2 , The tungsten film has very high purity and alm...

Embodiment 2

[0027] Carbon fiber (6.5 μm in diameter) is selected as the fiber material, and tungsten hexacarbonyl is selected as the metal carbonyl compound. Burn the carbon fiber at 400°C±10°C for 6 minutes, then soak it in 30% nitric acid solution for 10 minutes, wash it with deionized water and dry it; then place the pretreated carbon fiber in the deposition reaction chamber The raw material of tungsten hexacarbonyl is kept at a constant temperature of 150°C, argon is used as the carrier gas and diluent gas, the concentration of tungsten hexacarbonyl gas entering the deposition chamber is controlled to be about 0.5% (volume percentage), and the deposition reaction occurs at 350°C for 60 minutes. The surface of the carbon fiber is coated with a tungsten film with a thickness close to 70nm. According to the GB / T14337-2008 standard, the mechanical performance test shows that the toughness of the carbon fiber after tungsten plating is good, and the tensile strength retention rate of the ca...

Embodiment 3

[0029] Carbon fiber (6.5 μm in diameter) is selected as the fiber material, and nickel tetracarbonyl is selected as the metal carbonyl compound. Burn the carbon fiber at 410°C±10°C for 5 minutes, then soak it in 40% nitric acid solution for 5 minutes, wash it with deionized water and dry it; then place the pretreated carbon fiber in the deposition reaction chamber , the nickel tetracarbonyl raw material is kept at a constant temperature of 5°C, argon is used as the carrier gas and diluent gas, and the concentration of nickel tetracarbonyl gas entering the deposition chamber is controlled to be about 2% (volume percentage), and the deposition reaction occurs at 250°C for 10 minutes. The surface of the fiber is coated with a nickel film with a thickness of about 150nm. According to the mechanical performance test of GB / T14337-2008 standard, the carbon fiber has good toughness after nickel plating, and the tensile strength retention rate reaches 90%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com