Preparation of hydrogenation catalyst and use thereof

A hydrogenation catalyst and catalyst technology, applied in the direction of catalyst activation/preparation, catalyst carrier, physical/chemical process catalyst, etc., can solve problems such as catalyst poisoning, affecting performance, and excessive reduction in softening point of hydrogenated petroleum resin

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] The preparation of embodiment 1 catalyst carrier

[0048] Weigh 500g of pseudo-boehmite, 200g of aluminum hydroxide, 300g of diatomaceous earth and 100g of polyethylene glycol powder, mix well, add 276g of 6% dilute nitric acid aqueous solution for kneading, aging at room temperature for 30 minutes, and shape it on an extruder It is in the form of φ3 strips, dried at 120°C for 24 hours, and then fired at 800°C for 2 hours.

[0049] Cut the strip carrier into φ3×3 particle size and set aside.

[0050] Carriers 2, 3, 4, and 5 were prepared according to the above-mentioned preparation methods with different raw powder ratios. The composition and characterization of the carriers are shown in the following table:

[0051] Table 1 Carrier Raw Material Ratio and Carrier Characterization

[0052]

Embodiment 2

[0053] The loading of embodiment 2 active components

[0054] Weigh 100g of carriers 1 to 5 in Example 1, add 100ml (0.012g Sr / ml) of strontium nitrate aqueous solution to immerse for 24 hours, dry at 120°C for 12 hours, and then roast at 600°C for 4 hours to obtain a composite modified oxide Aluminum support, Sr content 1.2%.

[0055] Take 100g of the above-mentioned carriers 1, 2, 3, 4, and 5 respectively, put them into 120ml of a mixed aqueous solution containing palladium chloride and ruthenium chloride, wherein the palladium content is 0.00125g / ml, and the ruthenium content is 0.00083g / ml, and soak for 24 hours After drying at 120°C for 6 hours, the above operation was repeated 4 times to obtain a catalyst loaded with 0.6% Pd and 0.4% Ru. After drying, it was calcined at 400°C for 4 hours to obtain the corresponding C-1, C-2, C-3, C- 4. C-5 catalyst.

Embodiment 3

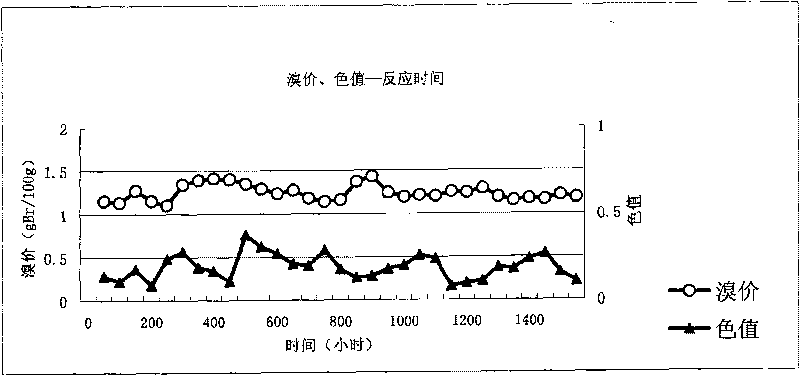

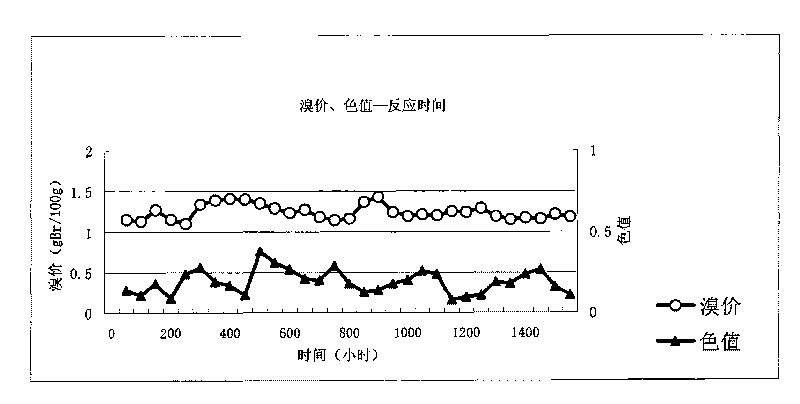

[0056] Embodiment 3 catalyst activity evaluation

[0057] Dissolve commercially available mixed C5 petroleum resin in cyclohexane solvent to form a raw material solution with a concentration of 20% (wt), wherein the chlorine content is 945ppm.

[0058] The physical properties of raw material mixed C5 petroleum resin are as follows:

[0059] Table 2 Raw material resin properties

[0060]

Color value (Gardner)

Chlorine content (ppm)

Bromine value (gBr / 100g)

Softening point (℃)

Hybrid carbon five petroleum resin

7.82

4728

70.47

106

[0061] The catalyst prepared in Example 2 was loaded into a single-tube fixed-bed reactor, and reduced at 300° C. for 4 hours in a hydrogen atmosphere under normal pressure to activate the catalyst, followed by hydrogenation reaction. The reaction conditions are as follows: temperature 270°C, pressure 8.0Mpa, liquid space velocity 4.0h -1 , hydrogen air velocity 200h -1 , the reaction mix...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com