Aluminum oxide sintered product and method for producing the same

A manufacturing method and alumina technology, which is applied in the field of alumina sintered body and its manufacture, can solve the problems of integrated circuit damage and small electrostatic adsorption force, and achieve the effects of reduced leakage current and increased corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

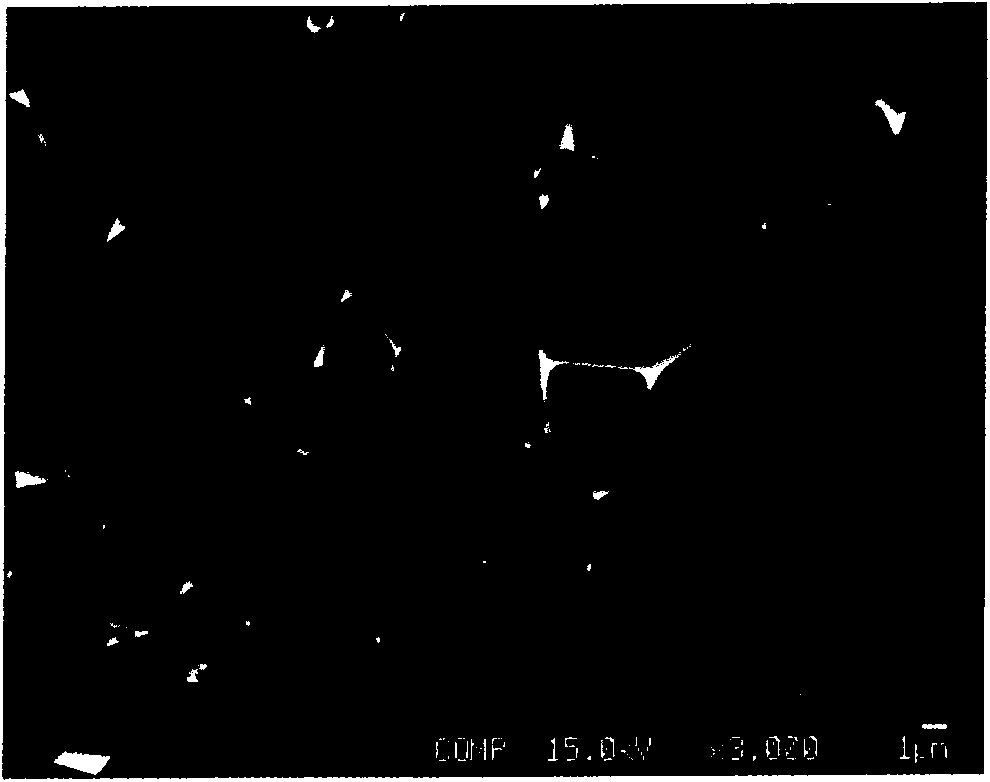

Embodiment 1

[0039] As the raw material powder, commercially available alumina (Al 2 o 3 ) powder, commercially available ytterbium fluoride (YbF 3 ) powder was wet-mixed for 4 hours using isopropanol as a solvent using a nylon jar and alumina balls with a diameter of 5 mm. The particle size of the raw material powder was measured by laser diffraction method. After mixing, the slurry was removed into a large tub and dried at 110° C. for 16 hours in a nitrogen stream. Then pass through a 30-mesh sieve to make blended powder. The resulting blended powder was mixed at 200kgf / cm 2 The pressure is uniaxially press-molded to produce a disc-shaped compact with a diameter of 50 mm and a thickness of about 20 mm, which is stored in a graphite mold for firing. Firing uses the hot pressing method. The pressurized pressure during firing is 100kgf / cm 2 , the atmosphere is a vacuum from room temperature to 1600°C, and then 1.5kgf / cm is introduced until the firing is completed at 1600°C 2 of nitr...

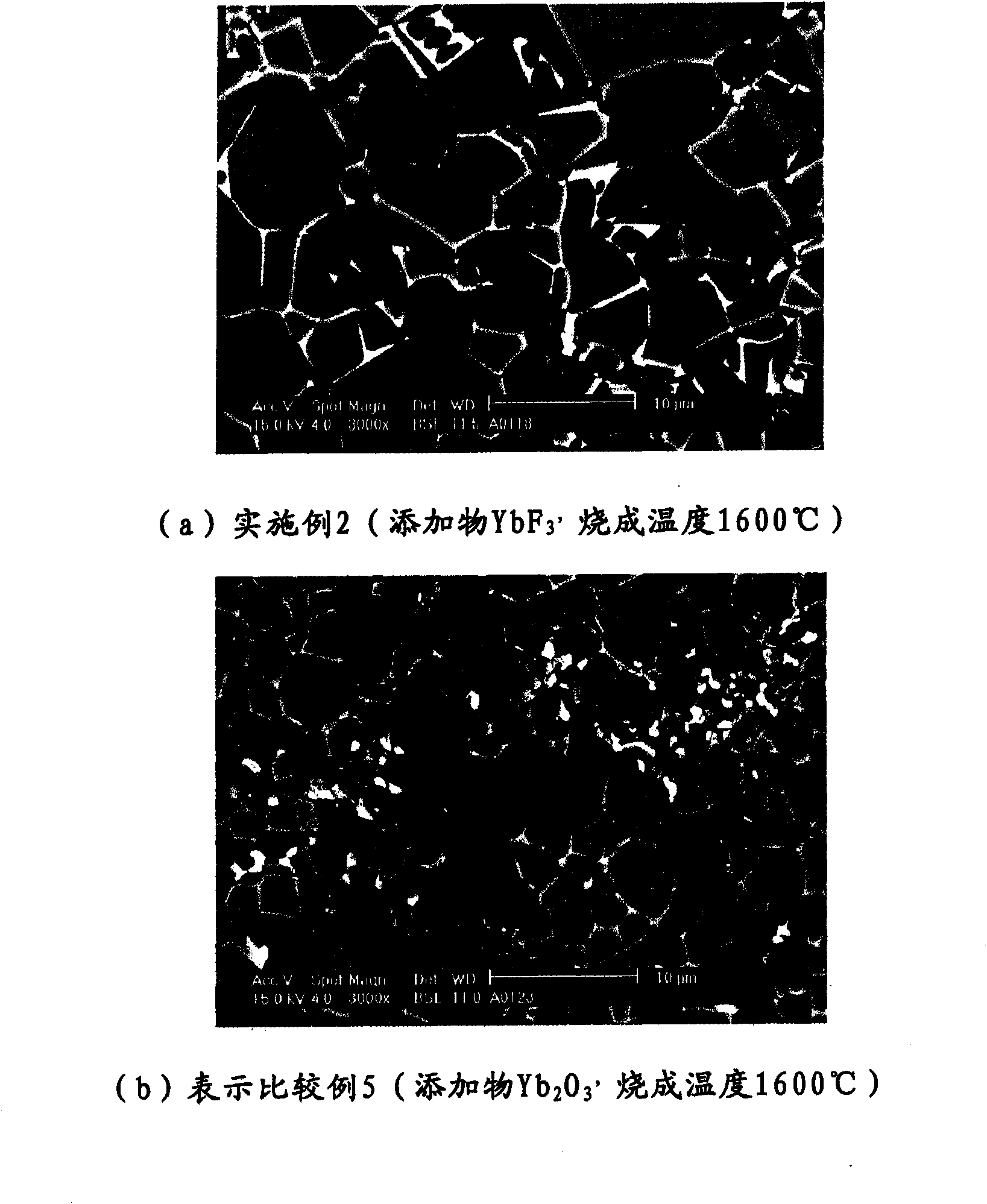

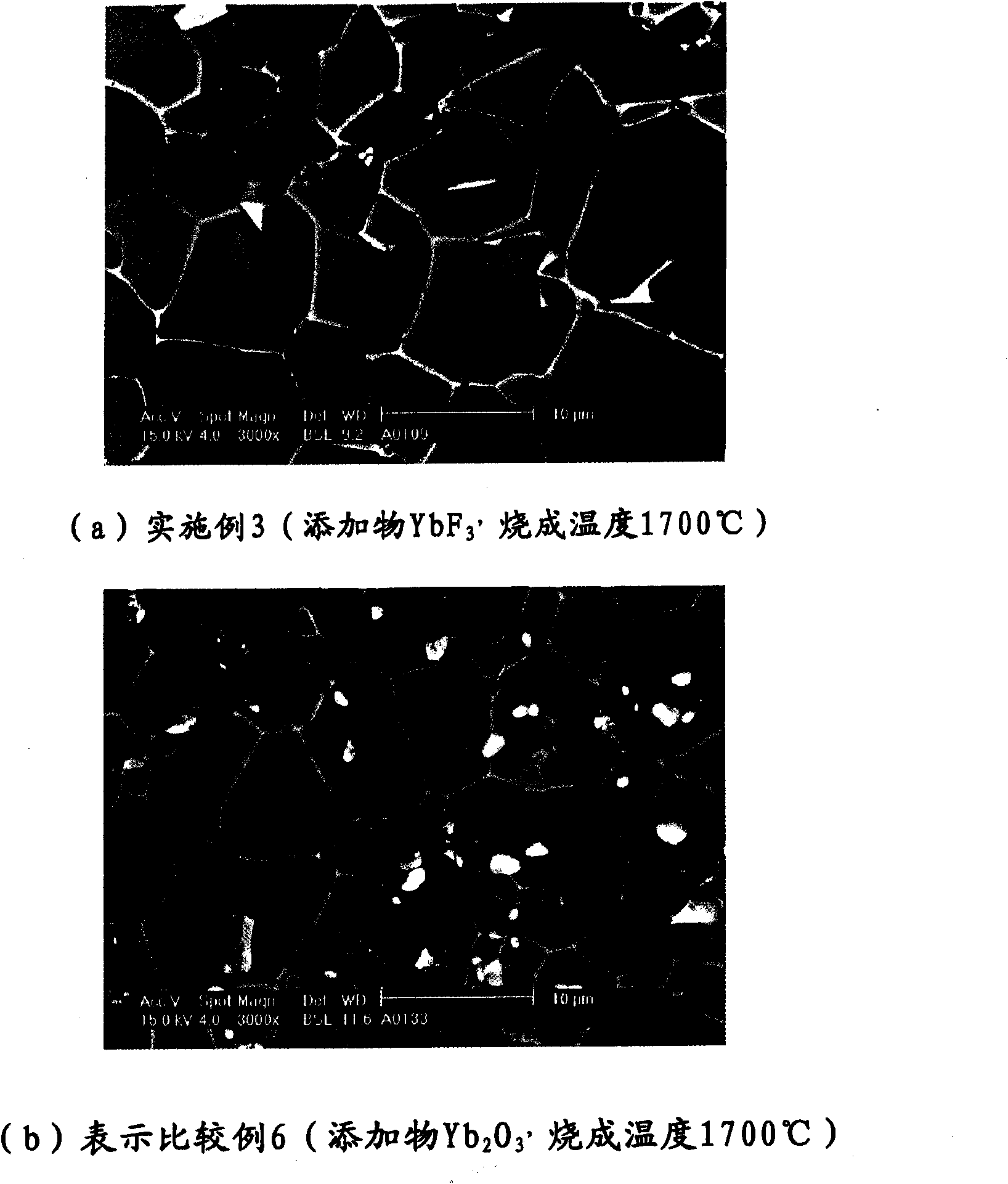

Embodiment 2~21、 comparative example 1~9

[0060] According to Example 1, the alumina sintered bodies of Examples 2 to 13 and Comparative Examples 1 to 9 were produced through the compositions and firing conditions in Table 1 and Table 2, and the same operations as in Example 1 were carried out (1) to (8) Determination of items. The results are shown in Table 1 and Table 2. When the firing temperature is 1700°C, the firing atmosphere is a vacuum from room temperature to 1600°C, and then 1.5kgf / cm is introduced during the period from 1600°C to 1700°C and until the firing is completed at 1700°C. 2 of nitrogen. In addition, in Comparative Example 9, since the firing was carried out in the air, the atmosphere was not particularly controlled.

[0061] As can be seen from Table 1, Examples 1 to 13, that is, for the fluoride (YbF 3 , YF 3 、LaF 3 ) mixture of alumina sintered by hot pressing and firing, the volume resistivity at room temperature is 1×10 13 ~1×10 16Ω·cm. Therefore, when these alumina sintered bodies are...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistivity | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com