Waterborne anti-corrosion coating composition and anti-corrosion coating method

A technology of anti-corrosion coatings and compositions, applied in anti-corrosion coatings, epoxy resin coatings, devices for coating liquids on the surface, etc., can solve problems such as inability to exhibit anti-corrosion properties, spot rust, etc., and achieve excellent storage stability , sufficient corrosion resistance, and the effect of reducing the total labor force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0177] The present invention is further explained below with reference to Examples. Hereinafter, "parts" and "%" represent "parts by mass" and "% by mass", respectively.

[0178] Production of water-reducible polyamine resin (A)

manufacture example 1

[0180] 3200 parts of "jER828" (trade name, manufactured by Mitsubishi Chemical Corporation; bisphenol A resin with an epoxy equivalent of 190 and a number average molecular weight of 375), 1700 parts of bisphenol A (molecular weight of 228), 900 parts of methyliso Butyl ketone and 5.0 parts of benzyldimethylamine were placed in a flask equipped with a stirrer, a thermometer, a nitrogen gas introduction tube, and a reflux condenser, and reacted at 120 °C until the epoxy equivalent per unit of non-volatile content It is 2500g / equivalent.

[0181] Then, 590 parts of a ketimidation product of 3,3'-diaminodipropylamine and methyl isobutyl ketone were added, and reacted at 120°C for 1 hour.

[0182] Then, 54 parts of deionized water and 380 parts of glycidyl neodecanoate were put therein, and reacted at 100° C. for 2 hours.

[0183] Thereafter, 90 parts of acetic acid and 70 parts of deionized water were added, and the inner solution was stirred and mixed. After adding 6,500 parts...

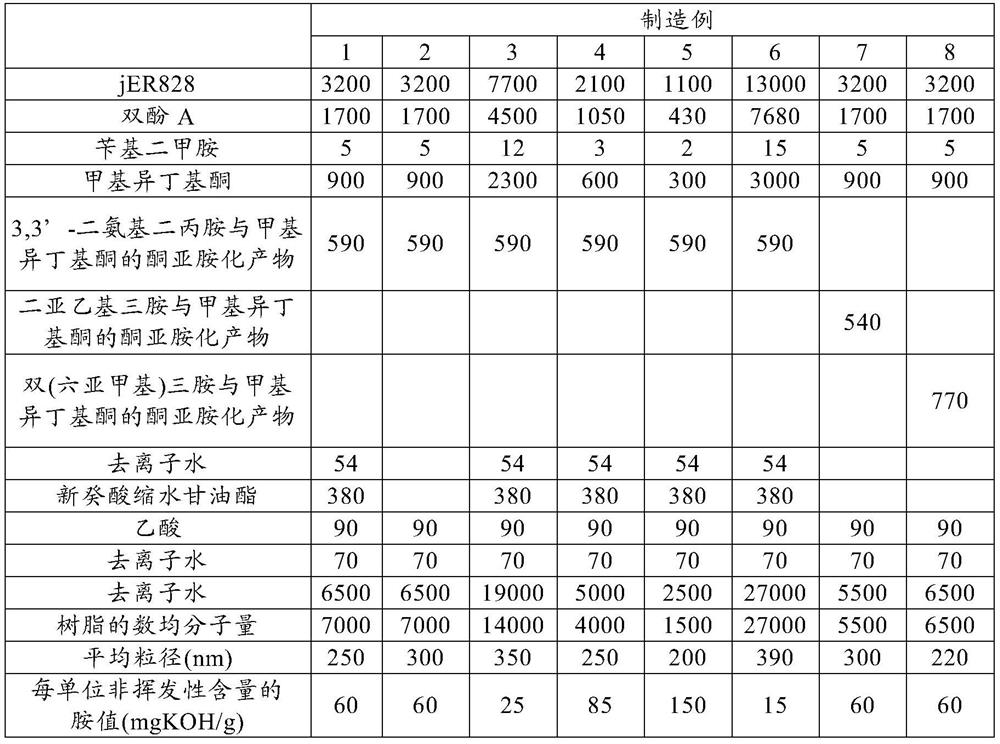

manufacture example 2 to manufacture example 8

[0186] Water-dilutable polyamine resins (A-2) to (A8) were produced in the same manner as above except for using the formulation composition of Table 1 below.

[0187] Table 1

[0188]

PUM

| Property | Measurement | Unit |

|---|---|---|

| amine value | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com