Self-adhesive rubber bituminous waterproof sheet material and preparation technology thereof

A technology of asphalt waterproof membrane and self-adhesive rubber, which is applied in water conservancy projects, asphalt layered products, shaft equipment, etc. It can solve the problems of water leakage, waterproof membrane cannot be tightly combined with the base of the building, and increase flexibility. High performance, good elasticity, and improved construction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

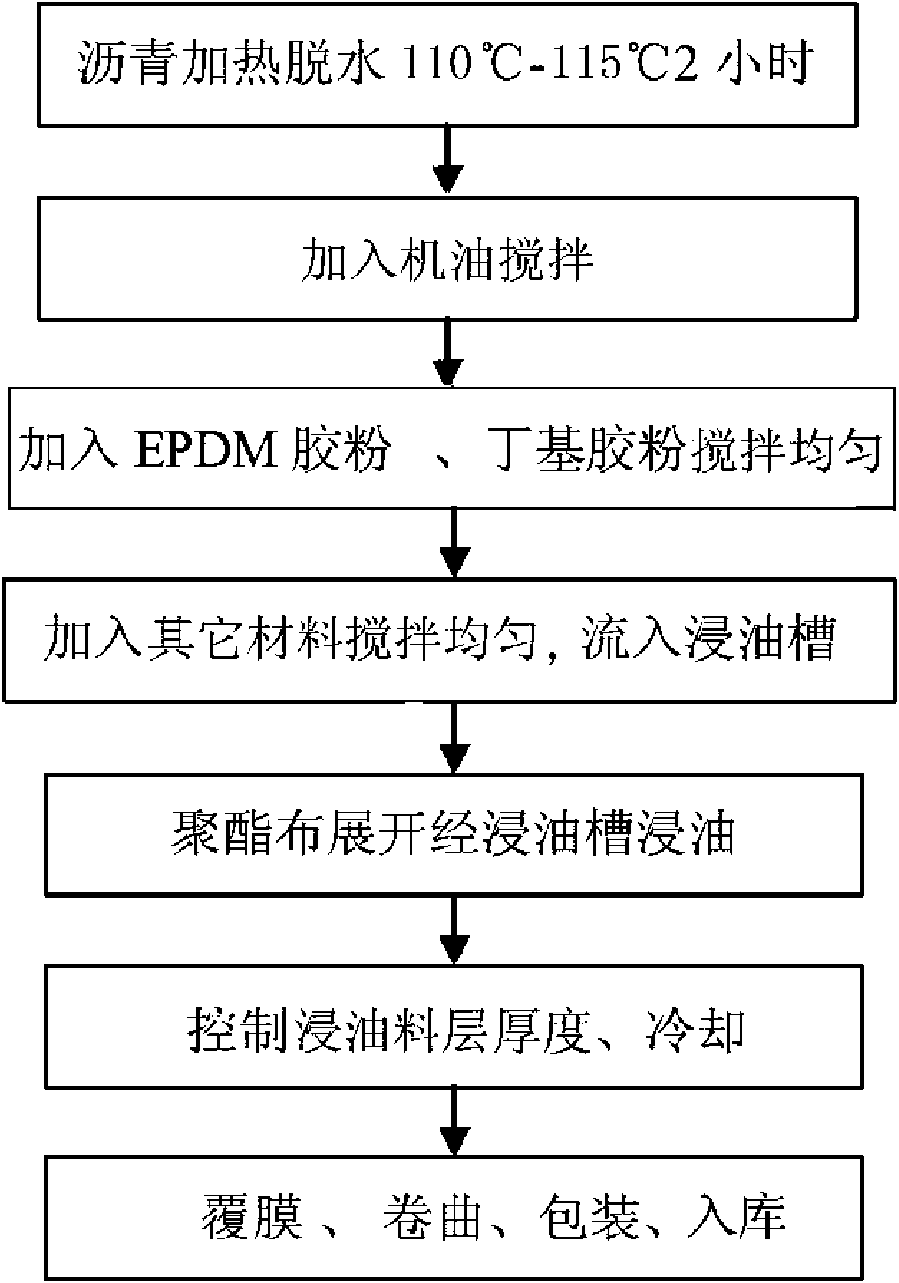

Method used

Image

Examples

Embodiment 1

[0040] Embodiment 1, this kind of self-adhesive rubber asphalt waterproof membrane includes polyester cloth, oil-soaked coating layer and film layer, and the material ratio of the described oil-soaked coating layer is as follows by mass:

[0041] 48 parts of 90# asphalt;

[0042] 5 parts of engine oil;

[0043] 8 parts of SBS glue;

[0044] 8 parts of SBR glue;

[0045] 8 parts of EPDM rubber powder;

[0046] 3 parts butyl rubber powder;

[0047] 15 parts of talcum powder;

[0048] 5 parts of petroleum resin.

Embodiment 2

[0049] Embodiment 2, this self-adhesive rubber asphalt waterproof membrane includes polyester cloth, an oil-soaked coating layer and a film layer, and the materials of the oil-soaked coating layer are proportioned as follows in parts by mass:

[0050] 45 parts of 90# asphalt;

[0051] 8 parts of engine oil;

[0052] 7 parts of SBS glue;

[0053] 7 parts of SBR glue;

[0054] 7 parts of EPDM rubber powder;

[0055] 5 parts of butyl rubber powder;

[0056] 18 parts of talcum powder;

[0057] 3 parts petroleum resin.

[0058] The oil-impregnated coating layer also contains an inorganic reinforcing agent or an organic reinforcing agent.

Embodiment 3

[0059] Embodiment three, this kind of self-adhesive rubber bitumen waterproof membrane includes polyester cloth, oil-soaked coating layer and film layer, and the material ratio of the described oil-soaked coating layer is as follows by mass:

[0060] 43 parts of 90# asphalt;

[0061] 15 parts of engine oil;

[0062] 5 parts of SBS glue;

[0063] 5 parts of SBR glue;

[0064] 5 parts of EPDM rubber powder;

[0065] 5 parts of butyl rubber powder;

[0066] Talcum powder 20 parts.

[0067] 2 parts petroleum resin.

[0068] The oil-impregnated coating layer also contains an inorganic reinforcing agent or an organic reinforcing agent.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com