Fast-recovery commutation diode used for high frequency electroplating and production method thereof

A technology of rectifier diodes and manufacturing methods, which is applied in semiconductor/solid-state device manufacturing, circuits, electrical components, etc., can solve the problems of deformation of large-diameter thin silicon wafers, reduce forward and reverse recovery time, and low blocking voltage, and achieve improved Effects of minority carrier life, fast reverse recovery, and high platinum concentration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

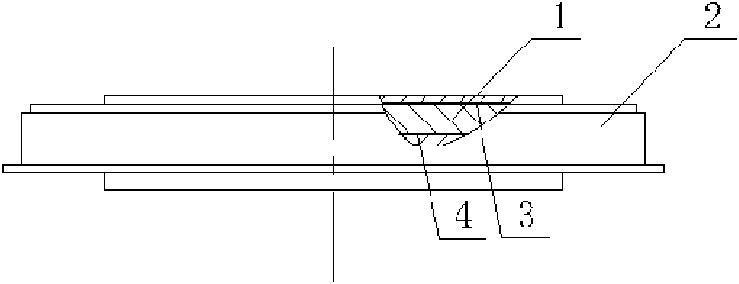

[0031] As shown in the figure, the fast recovery rectifier diode for high-frequency electroplating is composed of a shell 2 and a chip 1, and the chip 1 includes a base area N and a phosphorous expansion area N + and boron expansion area P + And cathode and anode ohmic contacts 3, 4, the chip 1 adopts N-type (100) radial low-resistance monocrystalline silicon wafer, the resistivity ρn of the monocrystalline silicon wafer is 5~9Ω-cm, and the diameter is 48mm , thickness 180±5μm, and pipe thickness 8±0.5mm, phosphorus expansion area N + and boron expansion area P + Formed by double-sided primary diffusion, the cathode and anode ohmic contacts 3 and 4 are titanium-nickel-gold or titanium-nickel-silver.

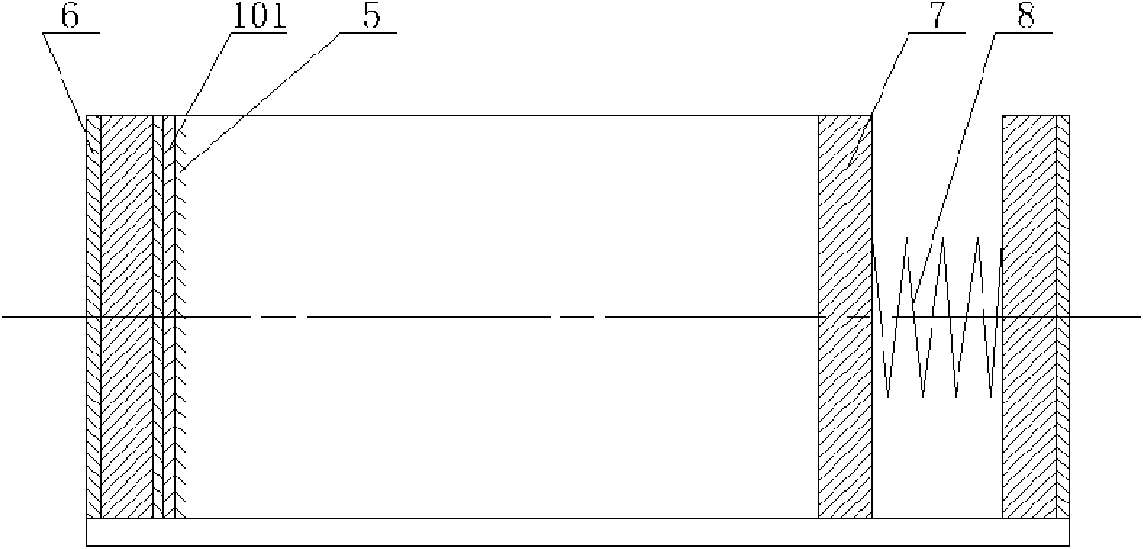

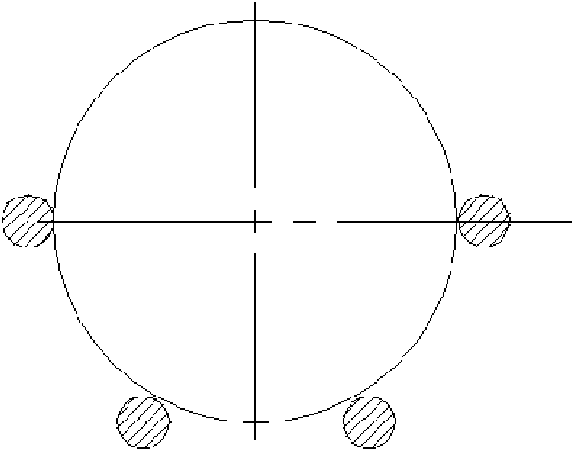

[0032] During manufacture, an N-type (100) radial monocrystalline silicon wafer 101 is used, with a resistivity ρn of 5-9Ω-cm, a diameter of 48mm, and a thickness of 180±5μm; after cleaning, the monocrystalline silicon wafer 101 is placed on On the silicon boat 6, N + ,P + P...

Embodiment 2

[0038] As shown in the figure, the fast recovery rectifier diode for high-frequency electroplating is composed of a shell 2 and a chip 1, and the chip 1 includes a base area N and a phosphorous expansion area N + and boron expansion area P + And cathode and anode ohmic contacts 3, 4, the chip 1 adopts N-type (100) radial low-resistance single crystal silicon wafer, the resistivity pn of the single crystal silicon wafer is 5 ~ 9Ω-cm, and the diameter is 70mm , thickness 180±5μm, and pipe thickness 8±0.5mm, phosphorus expansion area N + and boron expansion area P + Formed by double-sided primary diffusion, the cathode and anode ohmic contacts 3 and 4 are titanium-nickel-gold or titanium-nickel-silver.

[0039] During manufacture, an N-type (100) radial monocrystalline silicon wafer 101 is used, with a resistivity ρn of 5 to 9Ω-cm, a diameter of 70mm, and a thickness of 180±5μm; after cleaning, the monocrystalline silicon wafer 101 is placed on On the silicon boat 6, N + ,P ...

Embodiment 3

[0045] As shown in the figure, the fast recovery rectifier diode for high-frequency electroplating is composed of a shell 2 and a chip 1, and the chip 1 includes a base area N and a phosphorous expansion area N + and boron expansion area P + And cathode and anode ohmic contacts 3, 4, the chip 1 adopts N-type (100) radial low-resistance monocrystalline silicon wafer, the resistivity ρn of the monocrystalline silicon wafer is 5~9Ω-cm, and the diameter is 60mm , thickness 180±5μm, and pipe thickness 8±0.5mm, phosphorus expansion area N + and boron expansion area P + Formed by double-sided primary diffusion, the cathode and anode ohmic contacts 3 and 4 are titanium-nickel-gold or titanium-nickel-silver.

[0046] During manufacture, an N-type (100) radial monocrystalline silicon wafer 101 is used, with a resistivity ρn of 5-9 Ω-cm, a diameter of 60 mm, and a thickness of 180±5 μm; after cleaning, the monocrystalline silicon wafer 101 is placed on On the silicon boat 6, N + ,P ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com