A kind of mini LED chip and manufacturing method

A manufacturing method and chip technology, applied in the direction of semiconductor devices, electrical components, circuits, etc., can solve the problems of insufficient current resistance of metals, insufficient reliability of insulating layers, and large stress of insulating layers, etc., to achieve reliability and excellent performance of various types , high brightness and light extraction efficiency, and improved environmental corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

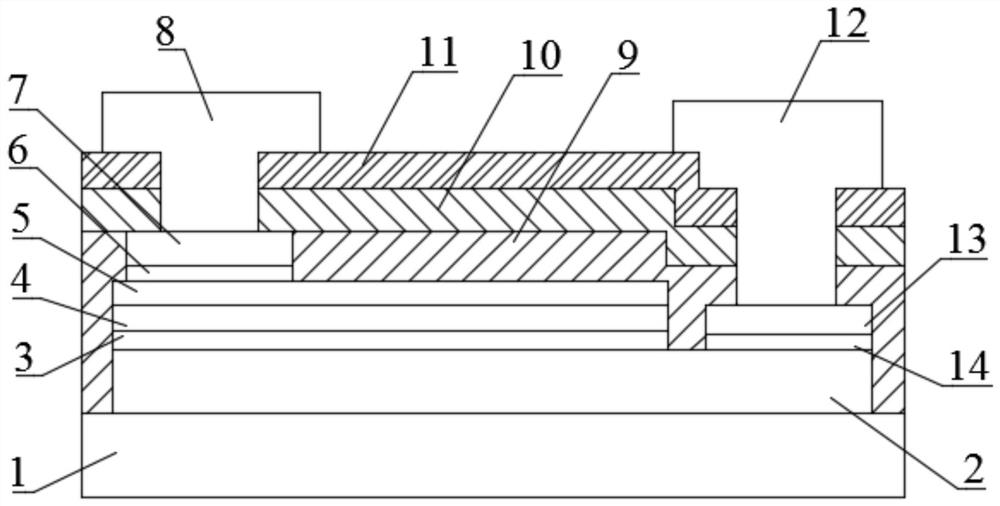

[0059] Please refer to figure 1 , Embodiment 1 of the present invention is:

[0060] A Mini LED chip, comprising a substrate layer 1, an N-type gallium nitride layer 2, a multilayer quantum well layer 3, a P-type gallium nitride layer 4, a current spreading layer 5, a P-type contact surface and a current stabilization layer 6, and a P-type gallium nitride layer. Type current injection layer 7, P type welding interface metal layer 8, buffer insulating layer 9, stress release layer 10, insulating full spectrum reflective layer 11, N type welding interface metal layer 12, N type current injection layer 13 and N type Contact surface and current stabilization layer 14.

[0061] Such as figure 1 As shown, the N-type GaN 2 is located in the middle region of the substrate layer 1, and one side of the N-type GaN 2 is sequentially stacked with a multi-layer quantum well layer 3, a P-type GaN layer 4, a current spreading layer 5, The P-type contact surface and current stabilization la...

Embodiment 2

[0067] Please refer to figure 1 , the second embodiment of the present invention is:

[0068] A method for manufacturing a Mini LED chip, comprising the following steps:

[0069] Use lithography equipment and materials such as photolithography machines and photoresists to perform pattern transfer according to the designed chip pattern, use ICP equipment to etch N-type GaN 2 on the middle position of the substrate layer 1, and use N-type GaN on the middle position of the substrate layer 1 On one side of 2, a multilayer quantum well layer 3 and a P-type gallium nitride layer 4 are sequentially fabricated;

[0070] A current spreading layer 5 is fabricated on the P-type gallium nitride layer 4 by means of evaporation. The material of the current spreading layer 5 can be indium tin oxide, indium tungsten oxide or nickel-gold alloy. The engraving facilities and materials are transferred according to the designed chip pattern, and the pattern is etched by chemical etching to obtai...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com