Bi-component elastomer polyurethane adhesive as well as manufacture method and application thereof

A technology of polyurethane adhesives and elastomers, applied in the direction of polyurea/polyurethane adhesives, adhesives, adhesive types, etc., can solve problems such as cancer and respiratory diseases, environmental and health hazards, environmental pollution and health, and avoid Health hazard, low condensable components, effects of high mechanical strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

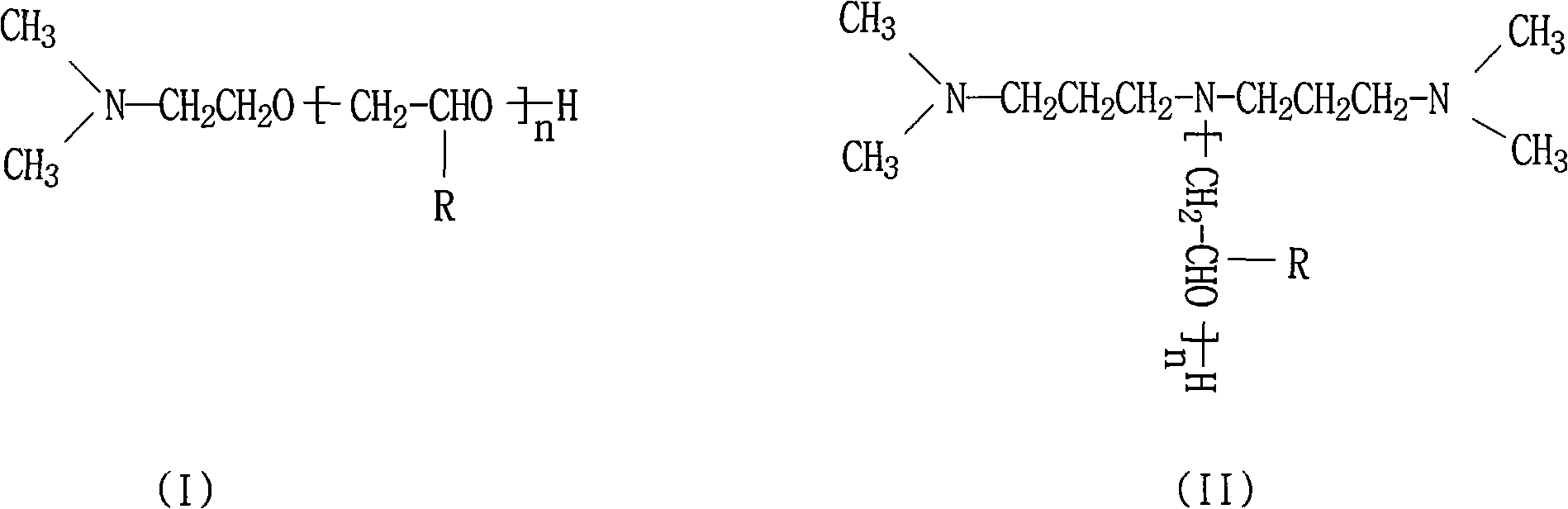

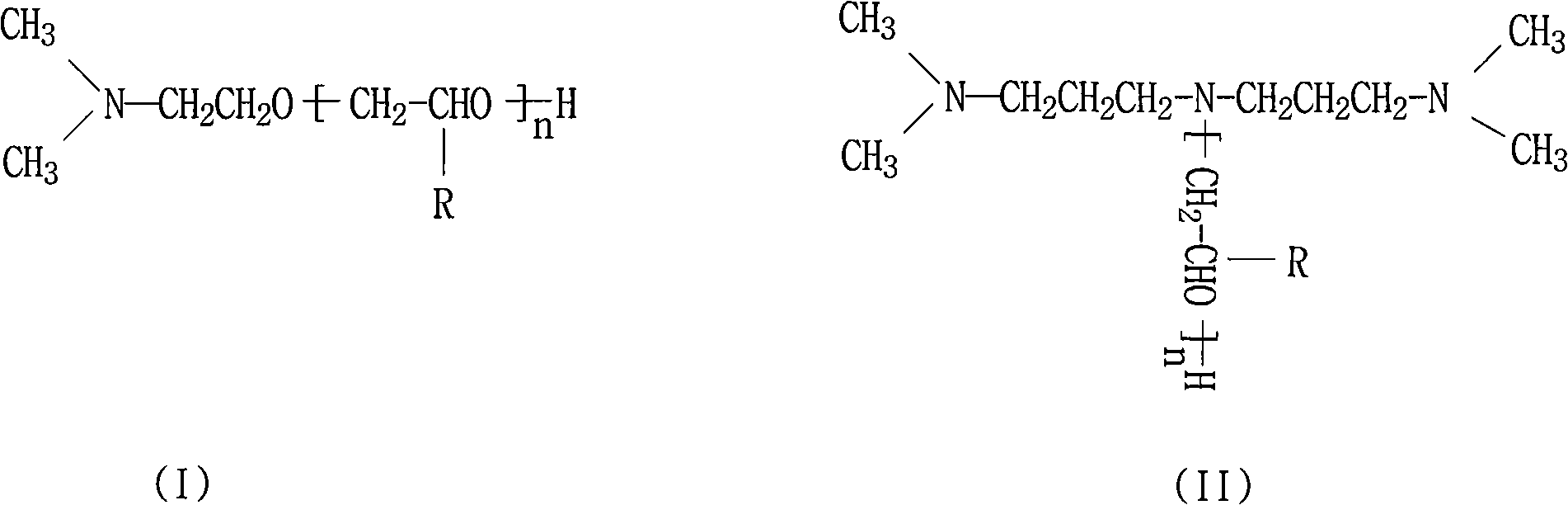

Method used

Image

Examples

preparation example Construction

[0045] Preparation of two-component polyurethane adhesive composition

[0046] The preparation of the polyurethane composition of the present invention includes the synthesis of component A and the preparation of component B.

[0047] Synthesis of Component A

[0048] Component A is a polyurethane prepolymer formed by the polymerization reaction of MDI and polyester polyol, and the polymerization process is a commonly used method in the technical field.

[0049] In this process, the polyester polyol can be dehydrated first, so as to avoid the side reaction of forming polyurea due to the presence of water, which will cause the quality of the prepolymer to decline.

[0050] In addition, MDI can be preheated before the polymerization reaction, such as heating to 60°C, to avoid uneven molecular weight distribution and unstable quality of the prepolymer caused by large temperature changes.

[0051] The polymerization reaction is controlled at 50-100°C, preferably 60-80°C; the...

Embodiment 1

[0071] 1. Synthesis of polyurethane prepolymer component A:

[0072] (1) Dehydration of polyester: first put a sufficient amount of L-144 poly(adipate-butylene glycol-ethylene glycol) ester into a reaction kettle with a stirrer and a vacuum system, and heat it to 120°C under stirring , and then evacuated to -0.09MPa, dehydrated for 120 minutes, and then cooled to room temperature for use.

[0073] (2) Preparation of prepolymer: put 100 parts of MDI-100 into another reaction kettle, under the protection of nitrogen, stir and heat up to 60°C, then add L- 72 parts of 144 polyester, the feeding rate is based on the fact that the exotherm of the reaction mixture does not exceed 80°C as the upper limit. After the polyester is added, the reaction is continued for 4 hours, cooled to room temperature, packaged, and sealed for storage.

[0074] 2. Preparation of curing agent component B:

[0075] 40 parts of GEP-330N polyether polyol, 10 parts of GJ-9701 polyether polyol, 50 parts of ...

Embodiment 2

[0078] 1. Synthesis of polyurethane prepolymer component A:

[0079] Pre-install the MDI-100 and 3051 is mixed evenly by weight 3:1. 100 parts of the mixed diphenylmethane diisocyanate, 80 parts of L-244 polyester, and the operating conditions and steps are the same as in Example 1.

[0080] 2. Preparation of curing agent component B:

[0081] GEP-560 polyether polyol 50 parts, GJ-9701 polyether polyol 20 parts, GPOP-H45 polymer polyol 40 parts, ethylene glycol 15 parts, trimethylolpropane 10 parts, NIAX black 028 color paste 5 Part, 0.005 part of ZR-50 reactive catalyst, operating conditions and steps are with embodiment 1.

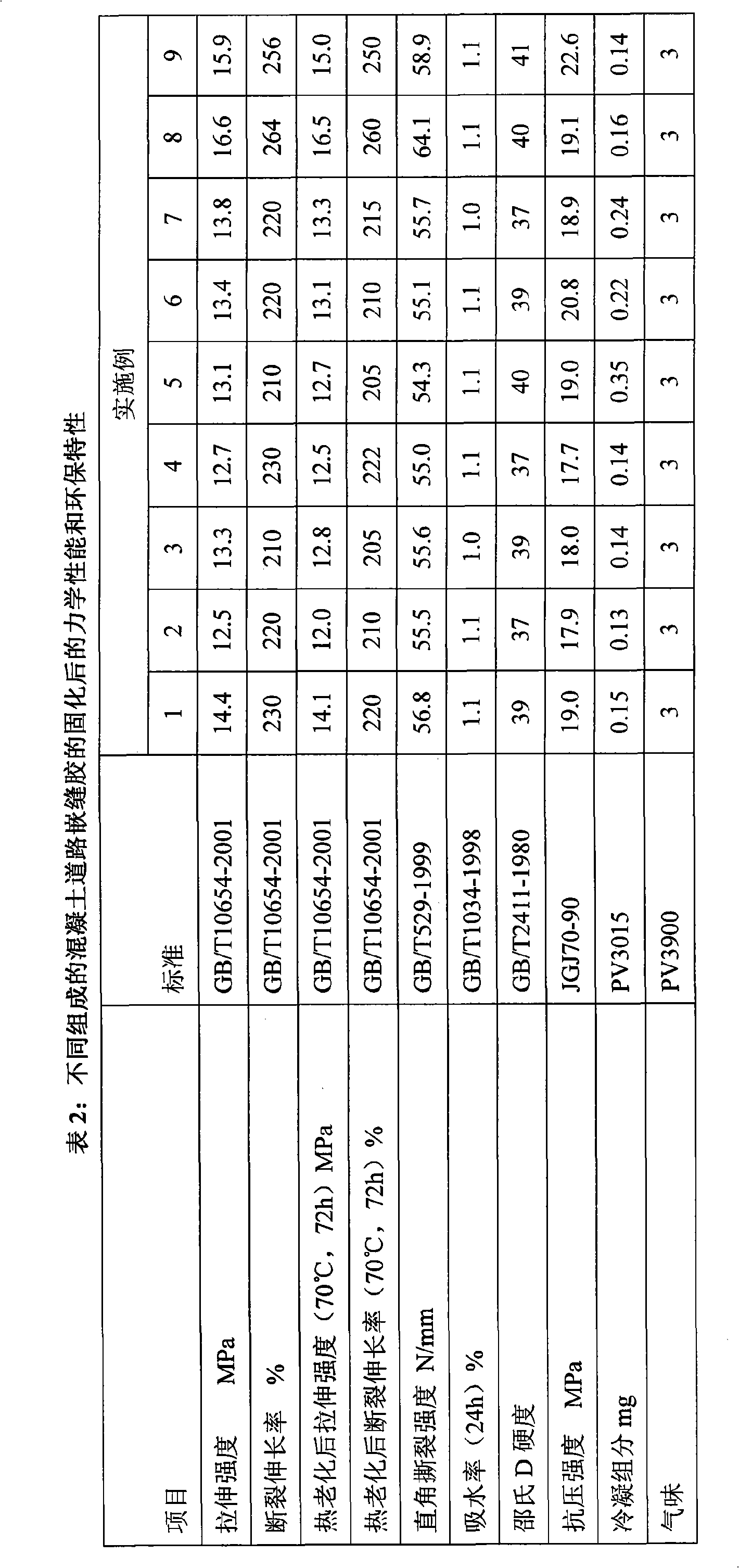

[0082] At 25°C, component A and component B were mixed evenly at a weight ratio of 2:1, and the curing speed was shown in Table 1; the mechanical properties and environmental protection characteristics of the cured material were shown in Table 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Tear strength | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com