Device and method for preparing cement and co-producing sulfuric acid by cooperating high-temperature liquid blast furnace slag with phosphogypsum/desulfurized gypsum

A technology for desulfurizing gypsum and blast furnace slag, which is applied in cement production, chemical instruments and methods, sulfur compounds, etc. It can solve problems such as long decomposition time, unstable strength, and large size, so as to increase the concentration of SO2 gas, reduce energy consumption and Equipment investment, avoiding the effect of complicated process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

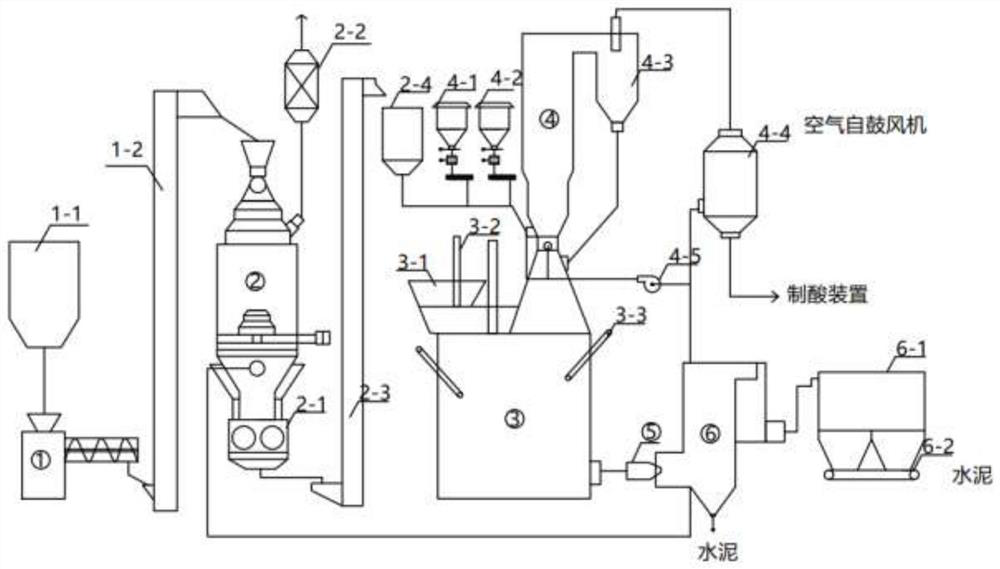

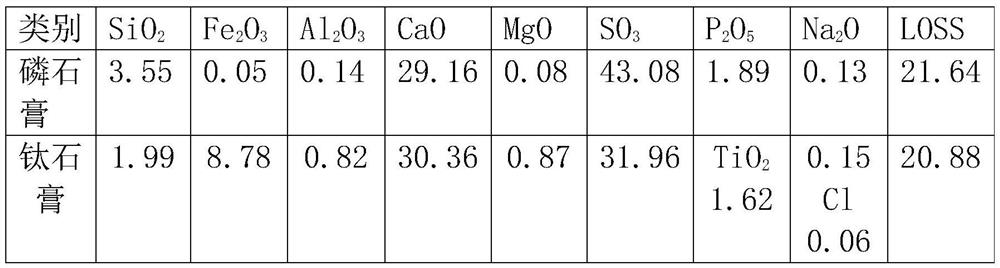

[0048] Embodiment 1: High-temperature liquid slag cooperates with phosphogypsum to make cement and co-produce sulfuric acid

[0049] Such as figure 1 As shown, in this embodiment, a device and method for co-producing sulfuric acid with high-temperature liquid slag in conjunction with phosphogypsum for cement production are provided, as follows:

[0050] Phosphogypsum gypsum has a high water content, contains soluble phosphorus, heavy metals, and fluoride, and needs to be washed with water. In this embodiment, in order to avoid the consumption of a large amount of water resources for washing, and to deal with the discharged sewage, the problem of increasing costs is to use a spiral The extruder squeezes out the physical water, and then enters the fixed bed drying furnace for drying and preheating while removing low-boiling fluorine and phosphorus, and the drying tail gas is washed and emptied. The detailed process is as follows:

[0051] Phosphogypsum first enters the molding ...

Embodiment 2

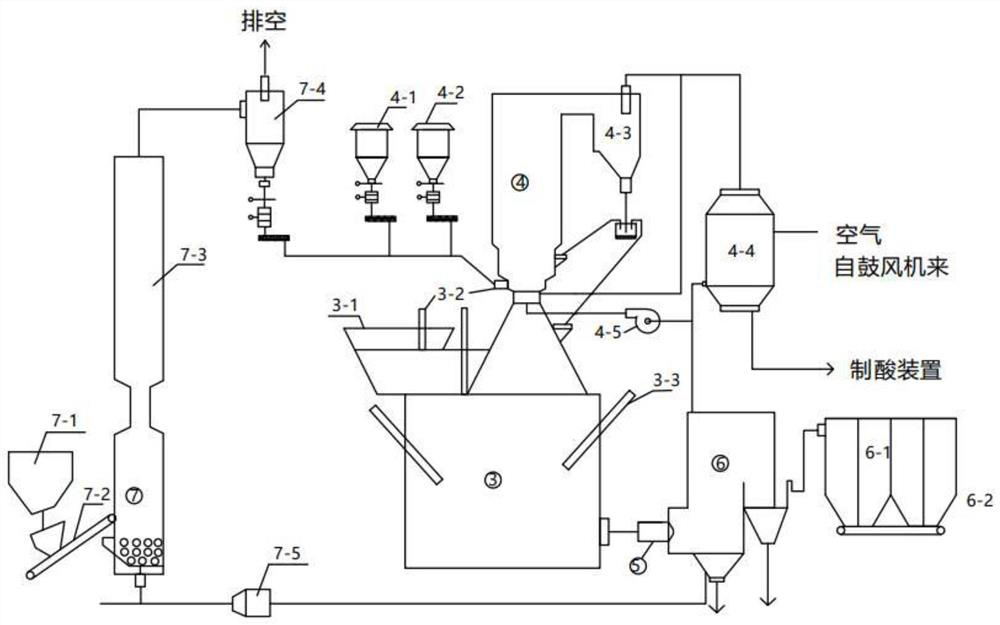

[0086] Example 2: High temperature liquid slag cooperates with desulfurization gypsum to make cement and co-produce sulfuric acid

[0087] In this embodiment, a high-temperature liquid slag is provided to cooperate with desulfurization gypsum to produce cement and co-produce sulfuric acid, as follows:

[0088] The desulfurized gypsum has low water content, and it can directly enter the fluidized bed equipped with ceramic balls combined with the air flow bed for drying and crushing, and the exhaust gas after drying is dedusted and emptied. The details are as follows:

[0089] The desulfurized gypsum first enters the drying and crushing system. The desulfurized gypsum passes through the silo 7-1 to control the feeding amount, and is transported to the conveyor 7-2 to the fluidized bed combined with entrained flow bed drying and crushing furnace 7; the fluidized bed combined with entrained flow bed is dried The furnace cloth air plate of the crushing furnace 7 is pre-installed wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com