Rust removing machine special for petroleum pipeline

A technology for oil pipelines and rust removal machines, which is applied in the direction of grinding workpiece supports, grinders, metal processing equipment, etc. The effect of reducing the duty cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

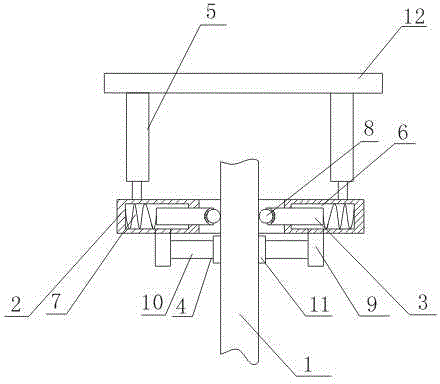

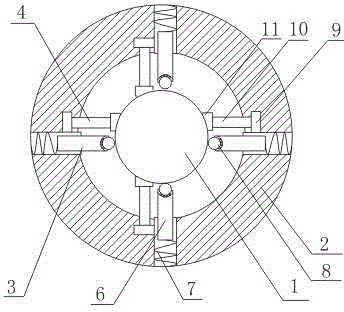

[0015] Such as figure 1 , figure 2 As shown, a derusting machine specially used for oil pipelines includes an annular rotating plate 2 sleeved on the outer diameter of the oil drill pipe 1, and the inner wall of the annular rotating plate 2 has a ring cavity; The clamping device 3 arranged in the ring cavity and the derusting device 4 fixed on the lower surface of the annular rotating plate 2; the clamping device 3 includes a support rod 6 which is slidably arranged in the ring cavity, and also includes two ends connected with the ring cavity respectively. The inner wall of the spring 7 connected to the rear end of the support rod 6, the front end of the support rod 6 passes through the opening of the ring cavity and is arranged outside the ring cavity, and also includes the universal ball 8 arranged at the front end of the support rod 6.

[0016] In this embodiment, when the annular rotating plate 2 is not sleeved on the oil drilling pipe 1, the spring 7 will be in the orig...

Embodiment 2

[0018] In this embodiment, on the basis of Embodiment 1, the derusting device 4 includes a connecting block 9, a connecting rod 10 connected to the connecting block 9, and a polishing body 11 fixed at the end of the connecting rod 10, and the side of the connecting block 9 is arranged on On the lower surface of the annular rotating plate 2.

[0019] The abrasive body 11 in this embodiment can derust the oil drill pipe 1 when the annular rotating plate 2 moves or rotates up and down along the axis of the oil drill pipe 1, and the effect of using a quartz stone abrasive sheet is better.

Embodiment 3

[0021] On the basis of Embodiment 1 or Embodiment 2, the present embodiment also includes a rotary table 12 arranged above the oil drilling rod 1 and a hydraulic cylinder 5 evenly arranged on the rotary table 12 around the rotating shaft of the rotary table 12. The piston rod is connected with the annular rotating plate 2.

[0022] The arrangement of the hydraulic cylinder 5 and the rotary table 12 in this embodiment can drive the annular rotating plate 2 to move up and down and rotate, without the need for staff to operate, the efficiency is high, and the working cycle is reduced.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com