Method for preparing lead magnesium niobate-lead titanate ferroelectric thin film

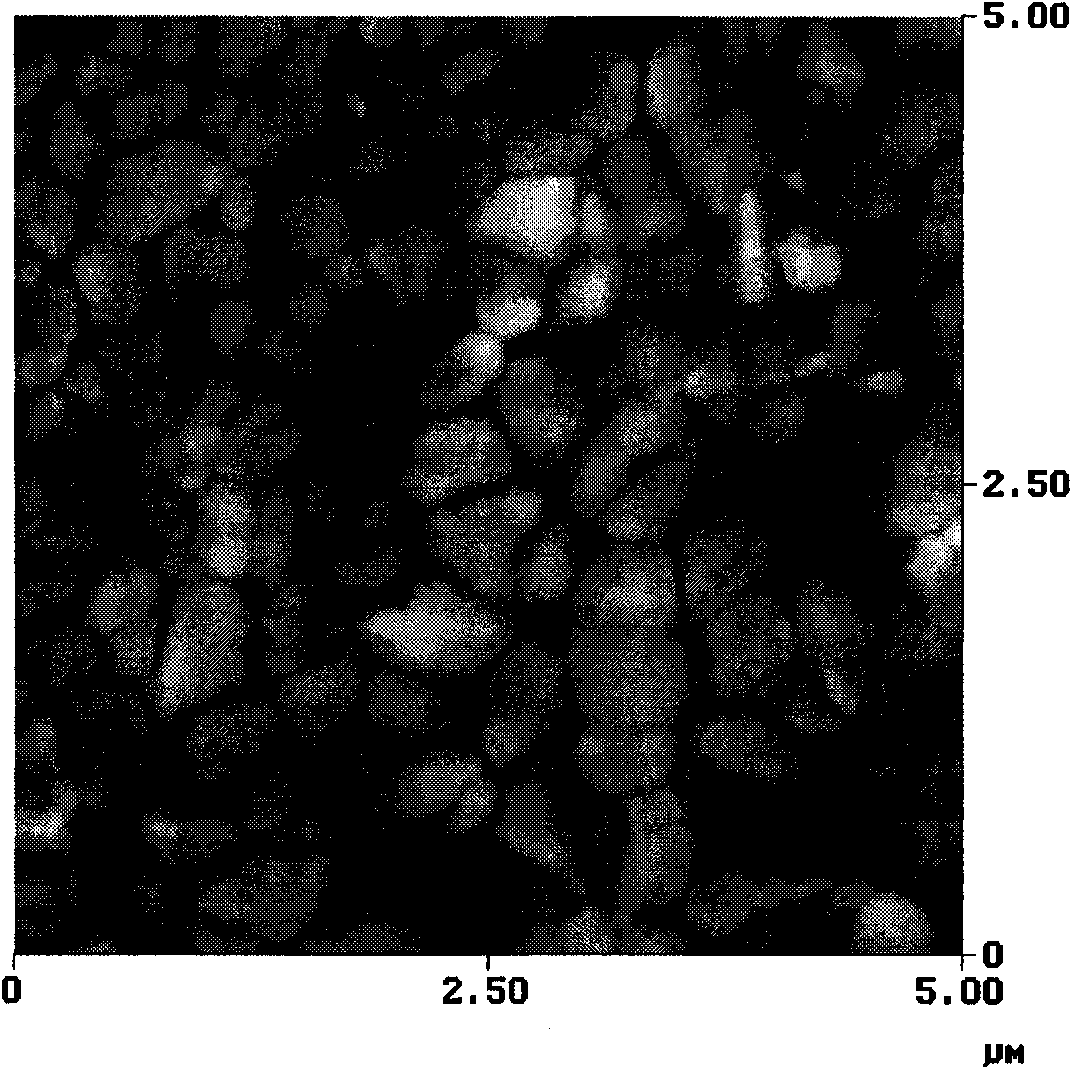

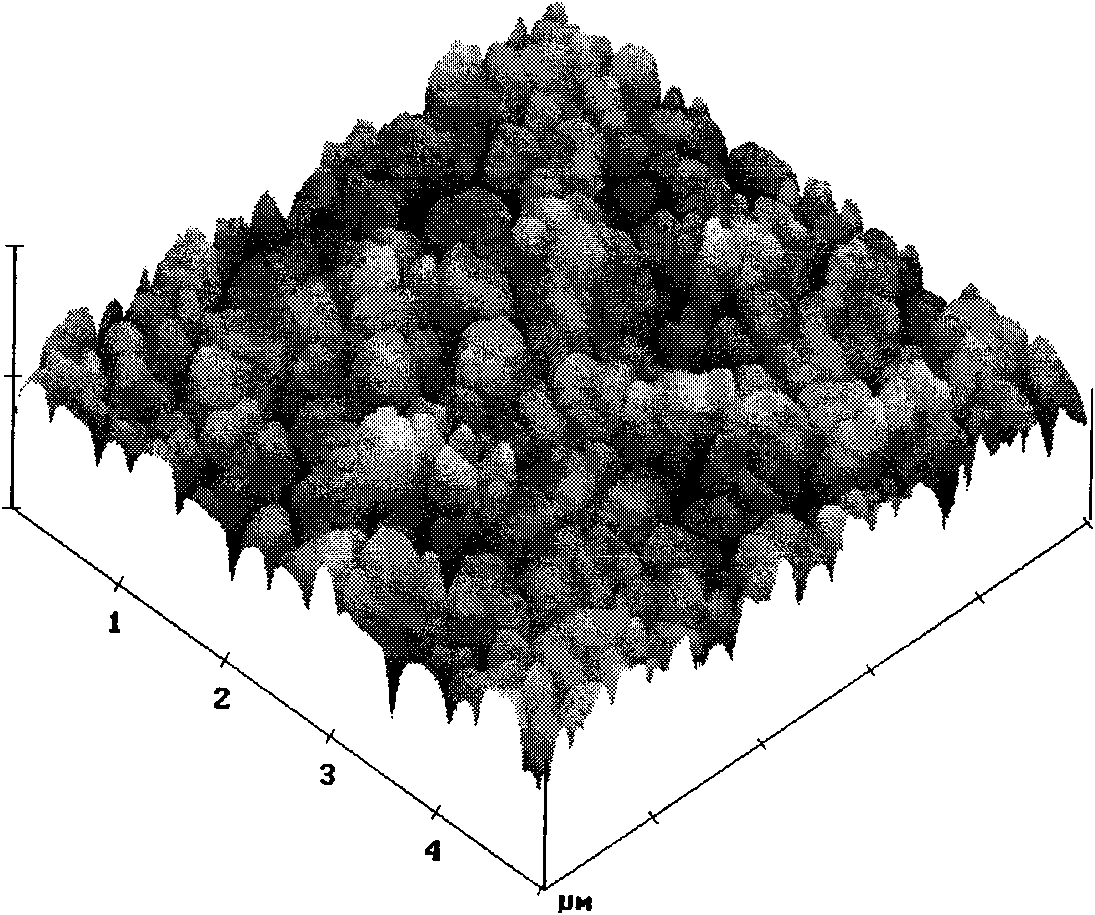

The technology of a ferroelectric thin film and lead magnesium niobate is applied in the field of preparation of ferroelectric thin films, and can solve the problems of poor ferroelectric properties, poor electro-optical properties and high sintering temperature of lead magnesium niobate-lead titanate ferroelectric thin films, Achieve the effect of smooth surface, enhanced ferroelectric properties and low sintering temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

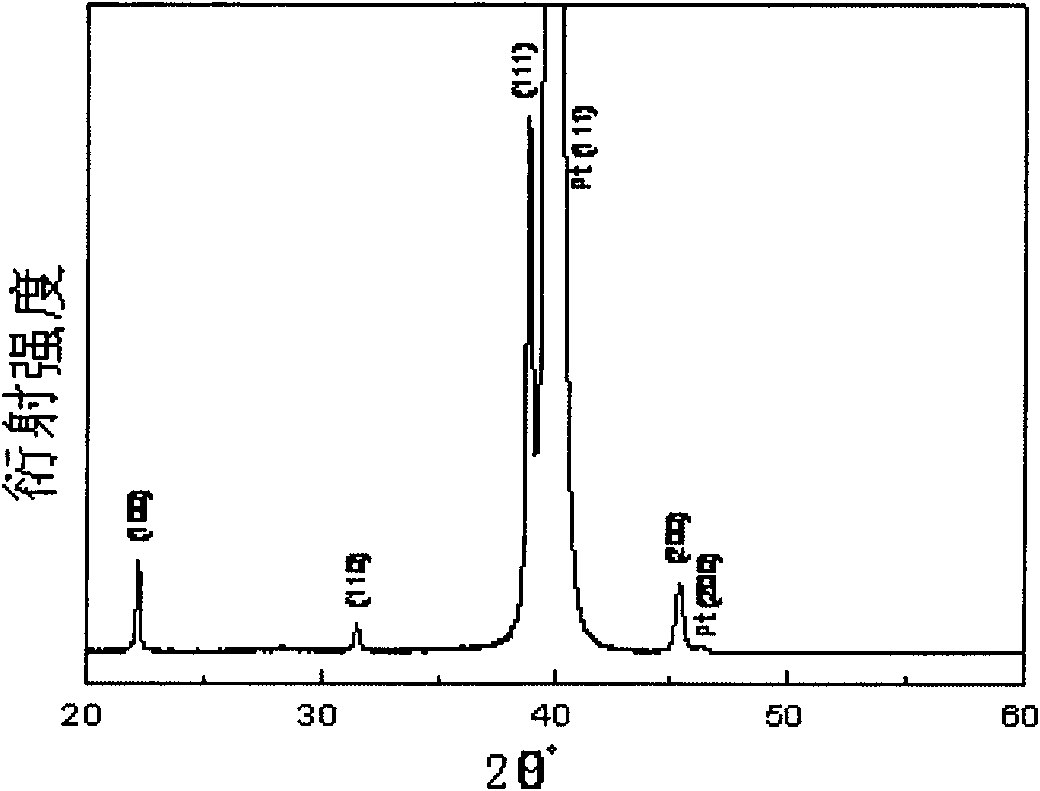

[0011] Specific embodiment 1: The method for preparing lead magnesium niobate-lead titanate ferroelectric thin film in this embodiment is implemented in the following steps: 1. According to the chemical formula (1-x)Pb(Mg 1 / 3 Nb 2 / 3 )-xPbTiO 3 , Weigh lead acetate, magnesium acetate, niobium ethoxide and tetrabutyl titanate according to the stoichiometric ratio, where 0.301 / 3 Nb 2 / 3 )-xPbTiO 3 Sol; 6. The substrate was sonicated in acetone and absolute ethanol for 4-6 minutes, and then placed in the air to dry naturally; 7. (1-x)Pb(Mg) was added dropwise to the substrate after step 6 1 / 3 Nb 2 / 3 )-xPbTiO 3 Sol, spin-coated for 10s under the condition of the homogenization speed of 1000~2000r / min, then spin-coated at the homogenization speed of 3500~4500r / min for 20s, and then dried at the temperature of 40~80℃. Film D; 8. Put film D in a rapid heat treatment furnace at a temperature of 630 to 650°C for 8 to 15 minutes, and cool to room temperature with the furnace to obtain a lead ...

specific Embodiment approach 2

[0016] The second embodiment: The difference between this embodiment and the first embodiment is that x=0.32 in step 1. Other steps and parameters are the same as in the first embodiment.

specific Embodiment approach 3

[0017] Specific embodiment three: the difference between this embodiment and specific embodiment one and two is that x=0.34 in step one. Other steps and parameters are the same as in the first embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com