Method for chemically synthesizing potassium sodium niobate nano-powder

A nano-powder and chemical synthesis technology, applied in the field of chemical engineering, can solve problems such as high cost, high powder calcination temperature, and complicated treatment, so as to reduce energy consumption and environmental pollution, reduce sintering temperature, process and production cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

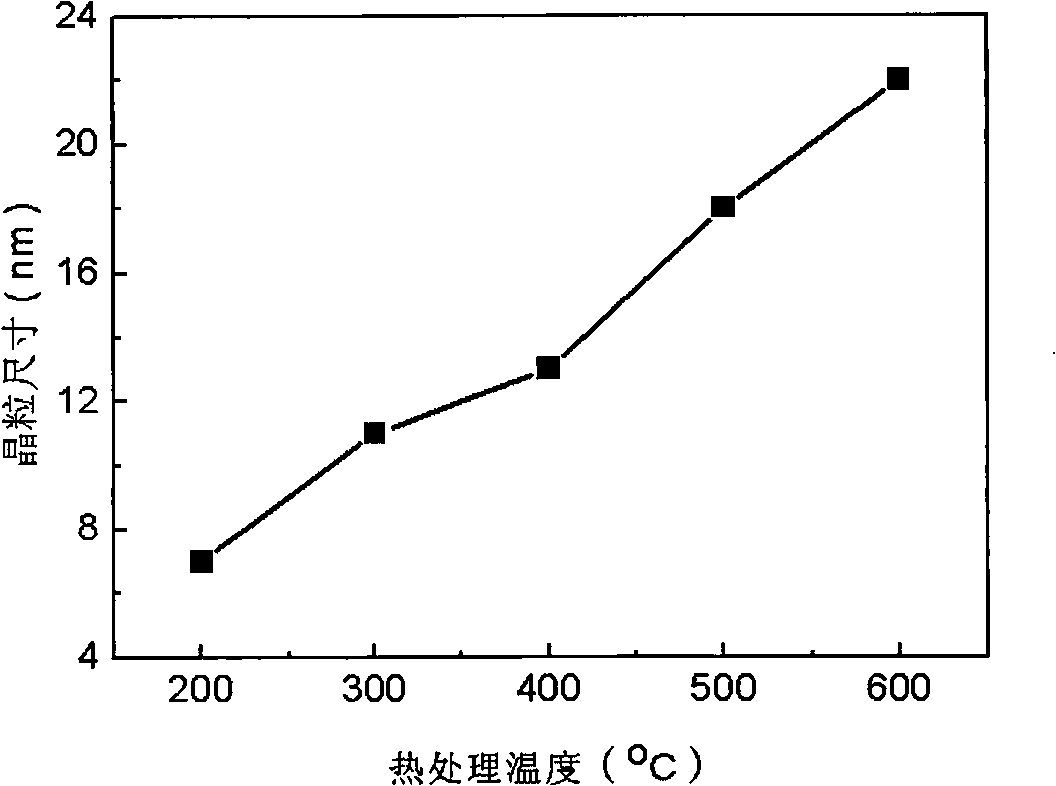

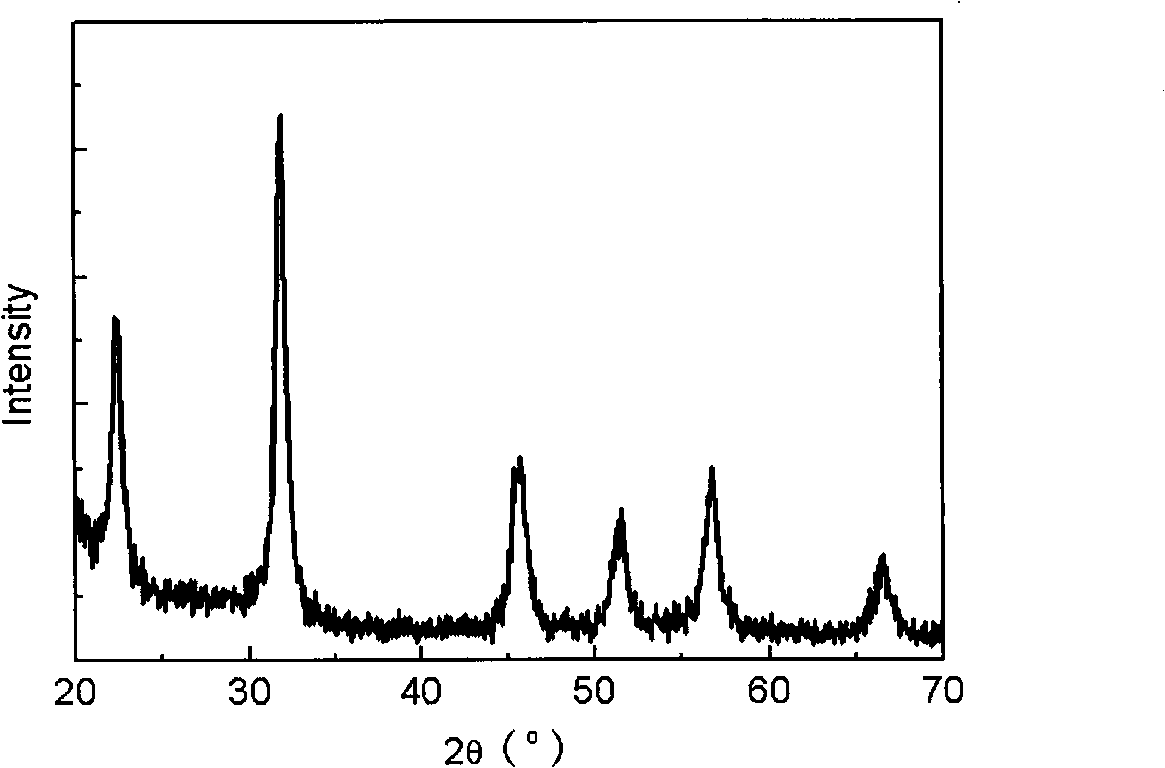

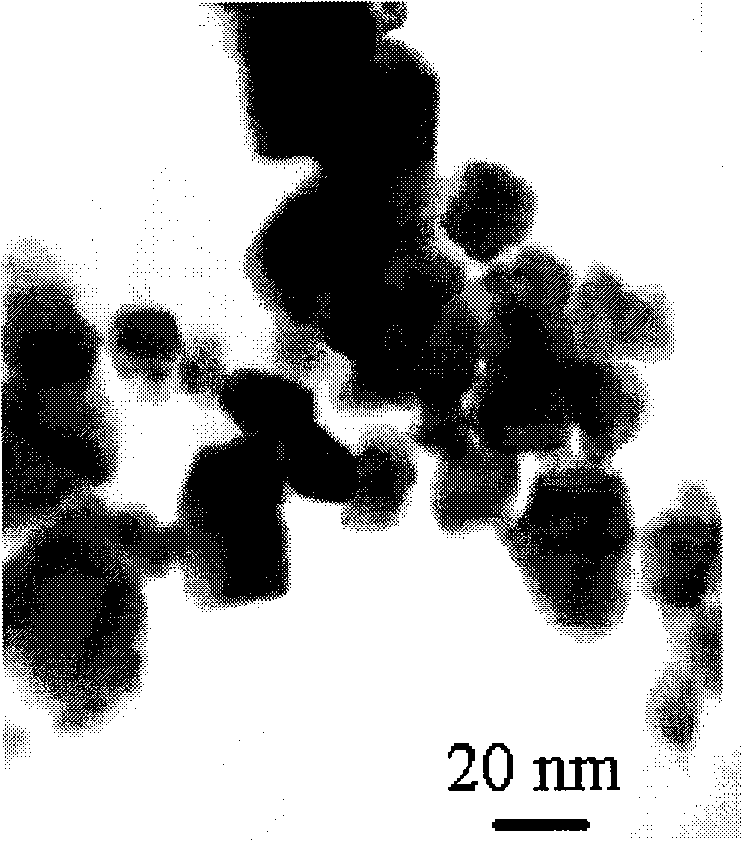

[0015] Analytical grade sodium ethoxide (NaOCH 2 CH 3 ), potassium ethoxide (KOCH 2 CH 3 ), niobium ethoxide (Nb[OCH 2 CH 3 ] 5 ) (prepared by the laboratory), according to the stoichiometric ratio of Na 0.5 K 0.5 NbO 3 Batching, three kinds of raw materials are dissolved in dehydrated alcohol; By mass percentage be the alkylphenol polyoxyethylene (10) ether (OP-10) of 8%, the n-butanol that mass percentage is 6%, mass percentage is 80% Cyclohexane and 4% pure water by mass percentage were prepared into a water / oil microemulsion system, and the temperature was maintained at 25°C; the ethanol solution containing sodium, potassium and niobium was slowly added dropwise to the microemulsion at 4 drops / min In the system, stir while adding dropwise, the stirring speed is 80 rpm, stir for 1 hour after the dropwise addition is completed, and then let it stand for 5 hours; wash the precipitated powder, and heat-treat at 300°C for 1 hour. Use X-ray diffraction to identify the p...

Embodiment 2

[0017] Analytical grade sodium ethoxide (NaOCH 2 CH 3 ), potassium ethoxide (KOCH 2 CH 3 ), niobium ethoxide (Nb[OCH 2 CH 3 ] 5 ) (prepared by the laboratory), according to the stoichiometric ratio of Na 0.5 K 0.5 NbO 3 Batching, three kinds of raw materials are dissolved in dehydrated alcohol; Be the alkylphenol polyoxyethylene (10) ether (OP-10) that mass percentage is 10%, the n-butanol that mass percentage is 10%, mass percentage is 70% Cyclohexane and 10% pure water by mass percentage were prepared into a water / oil microemulsion system, and the temperature was maintained at 25°C; the ethanol solution containing sodium, potassium and niobium was slowly added dropwise to the microemulsion at 6 drops / min In the system, stir while adding dropwise. The stirring speed is 100 rpm. After the dropwise addition is completed, stir for 1 hour, and then let it stand for 8 hours; wash the precipitated powder and heat-treat it at 200°C for 1 hour. Use X-ray diffraction to ident...

Embodiment 3

[0019] Analytical grade sodium ethoxide (NaOCH 2 CH 3 ), potassium ethoxide (KOCH 2 CH 3 ), niobium ethoxide (Nb[OCH 2 CH 3 ] 5 ) (prepared by the laboratory), according to the stoichiometric ratio of Na 0.5 K 0.5 NbO 3 Batching, three kinds of raw materials are dissolved in dehydrated alcohol; Be the alkylphenol polyoxyethylene (10) ether (OP-10) that mass percentage is 5%, the n-butanol that mass percentage is 5%, mass percentage is 85% Cyclohexane and 5% pure water by mass percentage were prepared into a water / oil microemulsion system, and the temperature was maintained at 25°C; the ethanol solution containing sodium, potassium and niobium was slowly added dropwise to the microemulsion at 4 drops / min In the system, stir while adding dropwise. The stirring speed is 80 rpm. After the dropwise addition is completed, stir for 1 hour, and then let it stand for 6 hours; wash the precipitated powder and heat-treat it at 300°C for 1 hour. Use X-ray diffraction to identify ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com