Selective diffusion technology for crystalline silicon solar cell

A technology of solar cells and diffusion technology, applied in circuits, photovoltaic power generation, electrical components, etc., can solve the problems of increasing process complexity, industrial application limitations, and increasing production costs, and achieve low equipment costs, high production efficiency, and short-wave efficiency high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

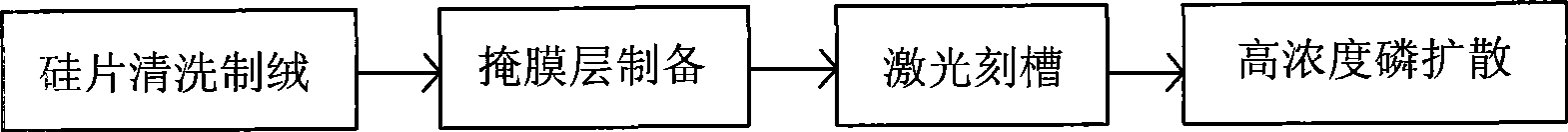

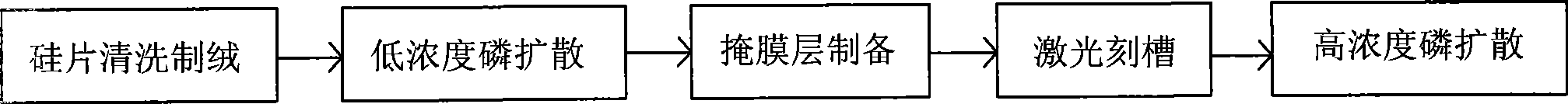

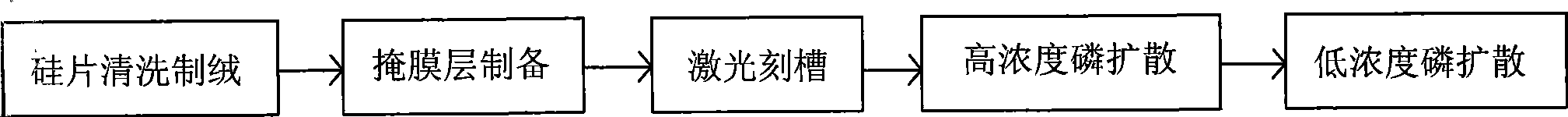

[0016] The present invention will now be described in further detail in conjunction with the accompanying drawings and preferred embodiments. These drawings are all simplified schematic diagrams, which only illustrate the basic structure of the present invention in a schematic manner, so they only show the configurations related to the present invention.

[0017] When the present invention is implemented, a mask layer with a thickness of 20nm-150nm is first prepared on the silicon wafer by thermal oxidation, evaporation or sputtering, and then a laser is used to scribe and groove on the mask layer according to the pattern of the positive electrode printed grid lines. And by adjusting the process parameters such as the frequency and power of the laser, different groove effects can be obtained, and the selective reflection structure can be formed by adjusting the parameters such as the thickness of the mask layer.

[0018] In the case of a thinner mask layer, heavy doping can be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com