Preparation of carbon fiber reinforced carbon-silicon carbide double matrix friction material

A technology of silicon carbide double and friction materials, applied in friction linings, mechanical equipment, etc., can solve the problems of low material density, large density gradient, poor material performance, etc. performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

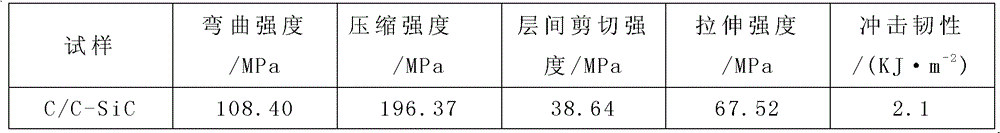

Examples

Embodiment 1

[0030] (1) Adopting the PAN type T700 (12K) chopped carbon fiber with a length of 15mm produced by Japan Toray Corporation (Toray), the graphite powder with a particle size of 0.1mm, the industrial silicon powder with a particle size of 0.05mm and the graphite powder with a particle size of 0.2mm Phenolic resin powder is the raw material. The volume content of the raw materials is 18% carbon fiber, 35% graphite powder, 7% industrial silicon powder and 40% phenolic resin powder. After mixing them, they are cold pressed at room temperature to form a density of 1.15g / cm 3 The C / C-Si block, the pressure is 2.0Mpa, and the holding time is 15min;

[0031] (2) Mechanically crush and granulate the C / C-Si block to obtain 70-80% of the C / C-Si particles whose particle size is mainly distributed between 5-15 mm, and the appearance of the particles is irregular ;

[0032] (3) Preheat the C / C-Si particles in step (2) at 120°C in an oven and keep it warm for 1.0h;

[0033] (4) Put the preh...

Embodiment 2

[0042] (1) Use PAN type XK-24 (24K) chopped carbon fiber with a length of 2mm produced by Dalian Xingke Carbon Fiber Co., Ltd., graphite powder with a particle size of 0.2mm, industrial silicon powder with a particle size of 0.05mm and a particle size of 0.05 mm of furan resin powder. The volume content of raw materials is 15% carbon fiber, 45% graphite powder, 10% industrial silicon powder and 30% phenolic resin powder, which are mixed and cold pressed at room temperature to form a density of 1.30g / cm 3 The C / C-Si block, the pressure is 2.0Mpa, and the holding time is 5min;

[0043] (2) Mechanically crush and granulate the C / C-Si block to obtain 70-80% of the C / C-Si particles whose particle size is mainly distributed between 5-15 mm, and the appearance of the particles is irregular ;

[0044] (3) Evenly spread the C / C-Si particles in step (2) and preheat in an oven at 100°C for 1.0h;

[0045] (4) Put the preheated C / C-Si particles into the mold and warm press to a density ...

Embodiment 3

[0053] (1) Adopting the PAN type T700 (12K) chopped carbon fiber, the graphite powder with a particle size of 0.075mm and the epoxy resin powder with a particle size of 0.01mm as the raw materials for the length of 15mm produced by Japan's Toray Corporation (Toray), the raw material The volume content is 10% carbon fiber, 35% graphite powder and 25% phenolic resin powder, which are mixed and cold pressed at room temperature to form a density of 1.10g / cm 3 The C / C-Si block, the pressure is 5.0Mpa, and the holding time is 10min;

[0054] (2) Mechanically crush and granulate the C / C-Si block to obtain 70-80% of the C / C-Si particles whose particle size is mainly distributed between 5-15 mm, and the appearance of the particles is irregular ;

[0055] (3) Preheat the C / C-Si particles in step (2) at 80°C in an oven and keep it warm for 1.5h;

[0056] (4) Put the preheated C / C-Si particles into the mold and warm press to a density of 1.40g / cm 3 The C / C-Si biscuit, the pressing pres...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com