Method for preparing nano complex particle for highly conductive and magnetic electro-magnetic screen

A nanocomposite particle and electromagnetic shielding technology, which is applied in the field of functional inorganic materials and nanoscience, can solve the problems of poor conductivity, anti-oxidation and acid and alkali resistance, low saturation magnetization, and poor frequency shielding performance, and achieve magnetic conduction and conduction Excellent performance, improved magnetic performance, and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

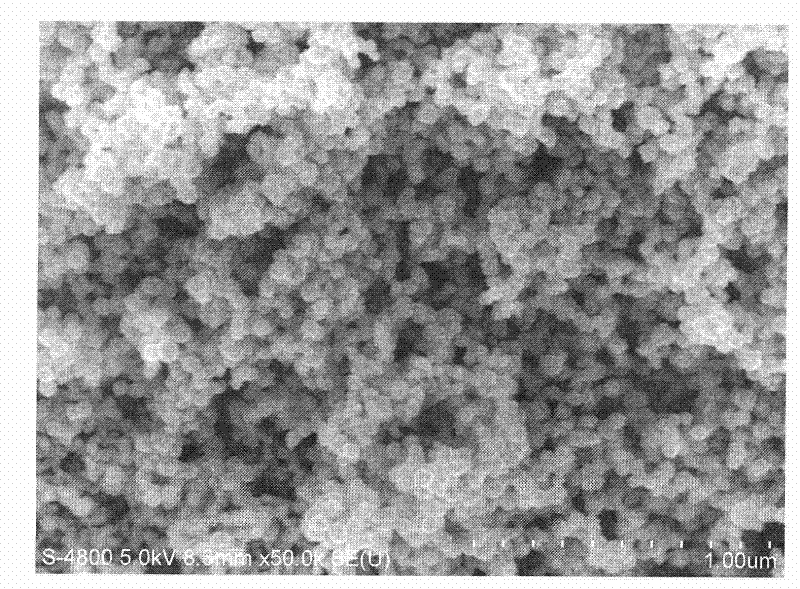

[0040] Get the ferrous salt and nickel salt that the total molar number is 0.005mol, wherein the molar number of ferrous salt accounts for 50%, that is, 0.72gFeSO 4 ·7H 2 O, 0.64g NiCl 2 ·6H 2 O, take another 0.017mol polyethylene glycol (PEG400) and 0.8ml cyclohexane, add water to 50ml, heat to 80°C after dispersion, add 20ml hydrazine hydrate (0.30mol) and 2.47 under ultrasonic conditions (100w, 40kHz) gNaOH mixed solution (use NaOH to adjust the pH value to 9-13), react for 30min, cool to room temperature, centrifuge wash three times, absolute ethanol wash twice, and vacuum dry at room temperature for 4h to obtain FeNi alloy nanoparticles, the morphology of which is shown in figure 1 , it can be seen that it is a spherical particle with a particle size of about 50nm and a relatively uniform particle size distribution. Hysteresis loop of FeNi alloy nanoparticles see Figure 9 ,Depend on Figure 9It can be seen that the magnetic saturation intensity is 86.7emu / g, and the...

Embodiment 2

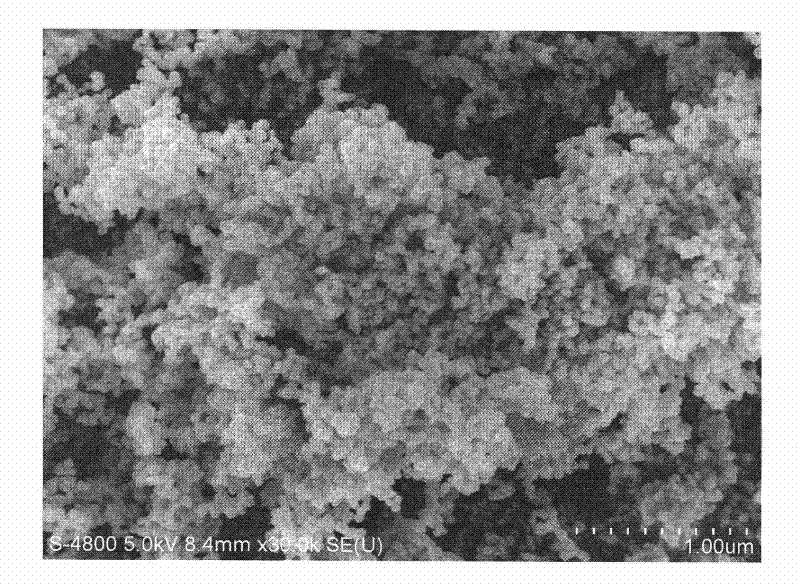

[0043] Get the ferrous salt and nickel salt that the total molar number is 0.005mol, wherein the molar number of ferrous salt accounts for 50%, that is, 0.72gFeSO 4 ·7H 2 O, 0.64g NiCl 2 ·6H 2 O, take another 0.017mol polyethylene glycol (PEG400) and 0.8ml cyclohexane, add water to 50ml, disperse and heat to 80°C, add 20ml hydrazine hydrate (0.30mol) and 2.47g NaOH under the condition of mechanical stirring (400rpm) (adjust the pH value to 9-13 with NaOH), react for 1 hour, mature for 30 minutes, wash three times with centrifugal water, wash twice with absolute ethanol, and then vacuum-dry at room temperature for 4 hours to obtain FeNi alloy nanoparticles, the morphology of which is shown in figure 2 , it can be seen that it is a spherical particle with a particle size of about 50 nm and a uniform particle size distribution.

[0044] Take 0.2g of FeNi alloy nanoparticles obtained above, 0.4g of glucose, add 50ml of absolute ethanol, ultrasonically disperse for 30min, add 5...

Embodiment 3

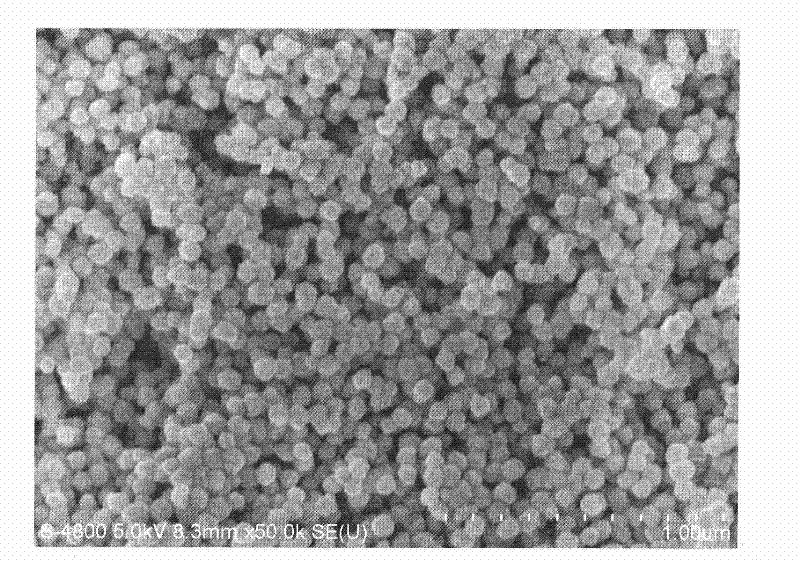

[0046] Get the ferrous salt and nickel salt that the total molar number is 0.005mol, wherein the molar number of ferrous salt accounts for 20%, that is 0.28gFeSO 4 ·7H 2 O, 0.95gNiCl 2 ·6H 2 O, take another 0.017mol polyethylene glycol (PEG400) and 0.8ml cyclohexane, add water to 50ml, disperse and heat to 80°C, add 20ml hydrazine hydrate (0.30mol) and 2.47g NaOH under the condition of mechanical stirring (400rpm) The mixed solution was reacted for 1 h, matured for 30 min, washed three times with centrifugation, washed twice with absolute ethanol, and then vacuum-dried at room temperature for 4 h to obtain FeNi alloy nanoparticles, the morphology of which is shown in image 3 , it can be seen that it is a spherical particle with a particle size between 50 and 100 nm and a uniform particle size distribution. Hysteresis loop of FeNi alloy nanoparticles see Figure 10 ,Depend on Figure 10 It can be seen that the magnetic saturation intensity is 71.9emu / g, and the hysteresis...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com