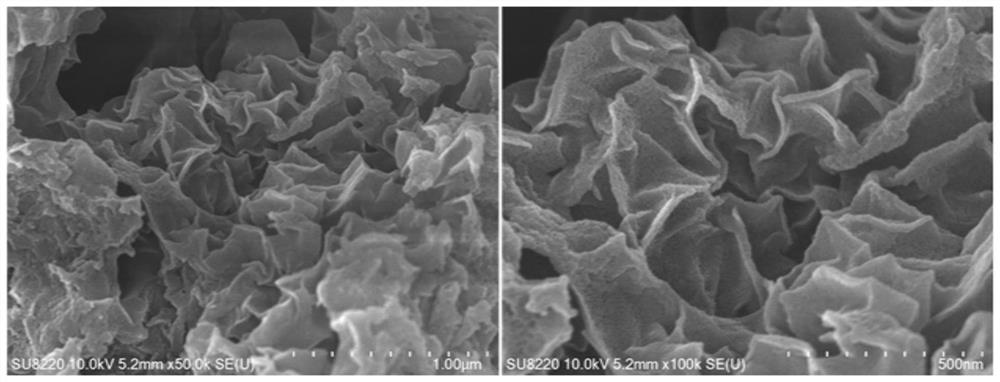

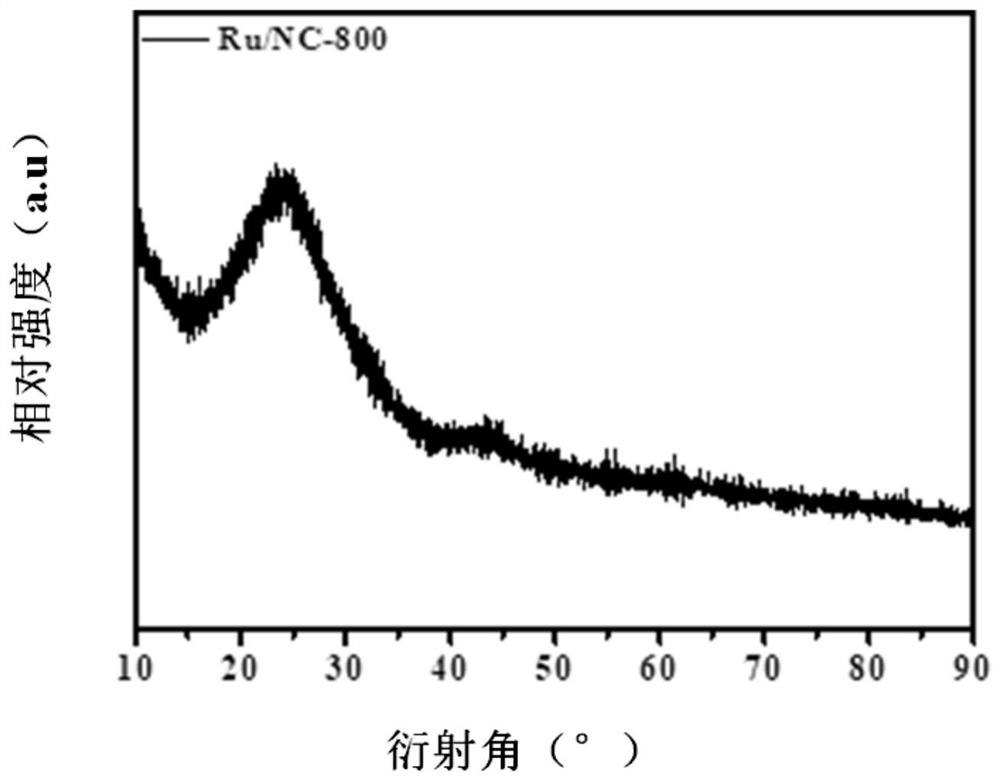

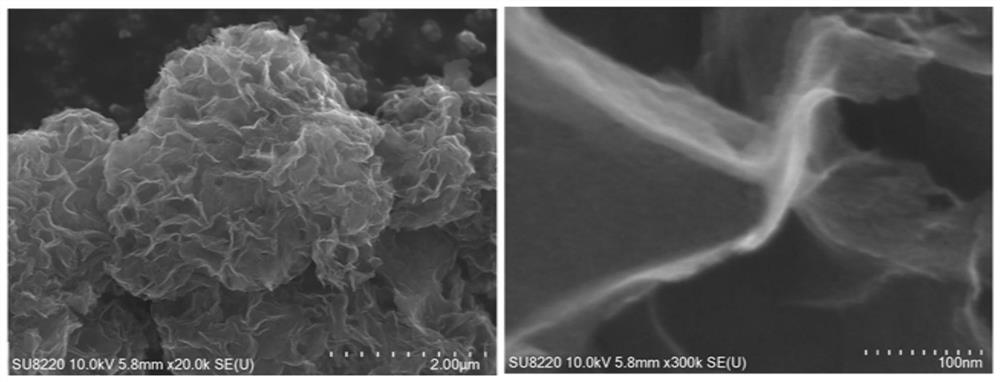

A kind of lignin-based nano-flower porous carbon carrier-loaded Ru-based catalyst and its preparation method and application in lignin depolymerization

A lignin-based, carrier-loaded technology, applied in chemical instruments and methods, physical/chemical process catalysts, metal/metal oxide/metal hydroxide catalysts, etc., can solve the problem of easy loss of active components and easy repolymerization of products etc. to achieve excellent activity, facilitate desorption, and easy control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0054] (1) Weigh 1 part by mass of alkali lignin, weigh 0.5 part by mass of magnesium oxide and add it to 20 parts by volume of water, and continue stirring at a speed of 300-500 rpm for 1 hour to form a uniform gray-yellow mixture.

[0055] (2) Transfer the mixture into a microwave reactor, raise the temperature to 200° C. for 5 minutes at a rate of 10° C. / min, and react for 5 minutes to obtain a light yellow mixture.

[0056] (3) Put the light yellow mixture into a freeze dryer at -50°C and dry for 24 hours to obtain a composite of lignin and magnesium oxide.

[0057] (4) transfer the compound obtained into the tube furnace, under N 2 Under the atmosphere of 3°C / min, the temperature was raised to 400°C at a constant temperature of 1h to obtain a black solid. After the calcined product was ground, it was mixed with 200 volume parts (2mol / L) of HCl, stirred at a speed of 400rpm for 12h, and statically After standing for 24 hours, filter, wash with water until neutral, and dry...

Embodiment 2

[0062] (1) Weigh 1 part by mass of enzymatic lignin, weigh 5 parts by mass of magnesium oxide and add it to 30 parts by volume of water, and continue stirring for 1 hour at a speed of 300-500 rpm to form a uniform gray-yellow mixture.

[0063] (2) Transfer the mixture into a microwave reactor, raise the temperature to 100° C. for 10 minutes at a rate of 60° C. / min, and react for 10 minutes to obtain a light yellow mixture.

[0064] (3) Put the light yellow mixture into a freeze dryer at -50°C and dry for 24 hours to obtain a composite of lignin and magnesium oxide.

[0065] (4) transfer the compound obtained into the tube furnace, under N 2 Under an atmosphere of 15°C / min, the temperature was raised to 800°C at a constant temperature of 6h to obtain a black solid. After the calcined product was ground, it was mixed with 200 parts by volume (2mol / L) of HCl, stirred at a speed of 400rpm for 12h, and statically After standing for 24 hours, filter, wash with water until neutral, ...

Embodiment 3

[0070] (1) Weigh 1 part by mass of the organic solvent lignin, add 1 part by mass of magnesium oxide into 30 parts by volume of water, and continue stirring for 1 hour at a speed of 300-500 rpm to form a uniform gray-yellow mixture.

[0071] (2) Transfer the mixture into a microwave reactor, raise the temperature to 50° C. for 30 minutes at a rate of 20° C. / min, and react for 30 minutes to obtain a light yellow mixture.

[0072] (3) Put the light yellow mixture into a freeze dryer at -50°C and dry for 24 hours to obtain a composite of lignin and magnesium oxide.

[0073] (4) transfer the compound obtained into the tube furnace, under N 2 Under an atmosphere of 10°C / min, the temperature was raised to 600°C at a constant temperature of 1h to obtain a black solid, and the calcined product was ground and mixed with 200 volume parts (2mol / L) of HCl, stirred at a speed of 400rpm for 12h, and statically After standing for 24 hours, filter, wash with water until neutral, and dry at 5...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com