A kind of corn cob derived activated carbon electrode material and preparation method thereof

An electrode material, corncob technology, applied in chemical instruments and methods, carbon compounds, inorganic chemistry, etc., can solve serious problems such as ammonia environmental pollution, and achieve high specific capacity, low cost, and easily controllable conditions.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Soak corncobs in 25% potassium hydroxide solution, the ratio of corncobs to potassium hydroxide is 1:3, fully soaked and dried, then calcined at 800 °C for 2 h, and then the obtained product was washed with dilute hydrochloric acid Wash with deionized water until the pH value of the solution is 7, and dry the obtained precipitate at 70° C. for 12 hours to obtain the first activated product.

[0030] The product activated for the first time and potassium hydroxide were fully ground and mixed in a mortar at a ratio of 1:3, and calcined at 800°C for 2 h, and the obtained product was washed with dilute hydrochloric acid and deionized water until the pH value of the solution was was 7, and the resulting precipitate was dried at 70°C for 12 hours to obtain a corncob-derived activated carbon electrode material.

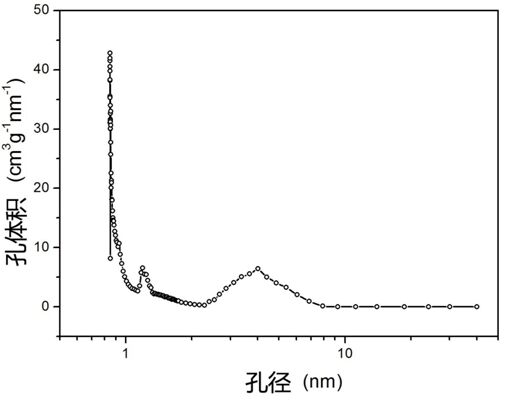

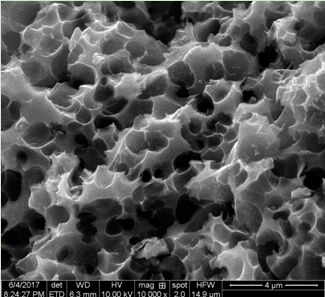

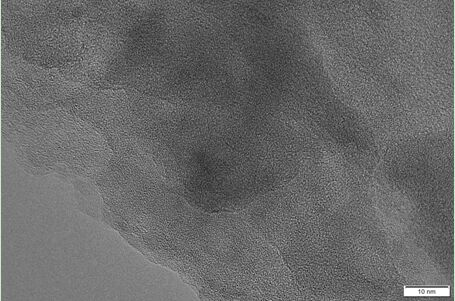

[0031] The pore size distribution of the prepared corncob-derived activated carbon electrode material is as follows: figure 1 shown by figure 1 It can be seen tha...

Embodiment 2

[0035] Soak corncobs in a 15% potassium hydroxide solution, the ratio of corncobs to potassium hydroxide is 1:1, fully soak and dry, and then calcined at 600 °C for 6 h, and then the resulting product is washed with dilute hydrochloric acid Wash with deionized water until the pH value of the solution is 7, and dry the obtained precipitate at 50° C. for 24 hours to obtain the first activated product.

[0036] The product activated for the first time and potassium hydroxide were fully ground and mixed in a mortar at a ratio of 1:0.5, and calcined at 600°C for 6 h, and the obtained product was washed with dilute hydrochloric acid and deionized water until the pH value of the solution was was 7, and the resulting precipitate was dried at 50°C for 24 hours to obtain a corncob-derived activated carbon electrode material.

[0037] In the prepared corncob-derived activated carbon electrode material, the average size of micropores is about 0.1 nm, and the average size of mesopores is a...

Embodiment 3

[0040]Soak corncobs in 50% potassium hydroxide solution, the ratio of corncobs to potassium hydroxide is 1:6, fully soak and dry, and then calcined at 1000 °C for 1 h, and then the obtained product is treated with dilute hydrochloric acid Wash with deionized water until the pH value of the solution is 7, and dry the obtained precipitate at 120° C. for 6 hours to obtain the first activated product.

[0041] The product activated for the first time and potassium hydroxide were fully ground and mixed in a mortar at a ratio of 1:6, and calcined at 1000°C for 1 h, and the obtained product was washed with dilute hydrochloric acid and deionized water until the pH value of the solution was was 7, and the resulting precipitate was dried at 120°C for 6 hours to obtain a corncob-derived activated carbon electrode material.

[0042] In the prepared corncob-derived activated carbon electrode material, the average size of micropores is about 1 nm, and the average size of mesopores is about ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com