A method for controlling the pore size of open-cell foamed copper

A technology of open-cell foam and copper foam, which is applied in the direction of cells, electrolysis, electroforming, etc., can solve the problems of large pore size, complex process, and difficult regulation of foam copper, and achieve low cost, simple process conditions, and increased skeleton size. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

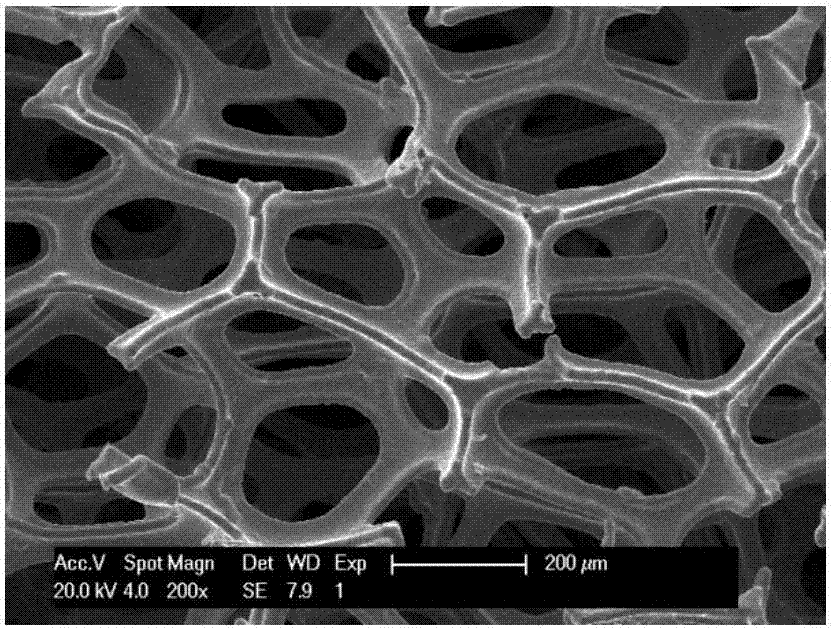

[0031] A copper foam with a thickness of 1.5 mm and a pore size of 450 μm was selected as the cathode, and cleaned with acetone and ethanol in an ultrasonic environment of 100 W power for 10 min, blown dry with nitrogen, and immersed in 1 mol / L hydrochloric acid aqueous solution for 3 min to remove the oxide film on the surface. And activate the surface of foamed copper tendons, take it out, wash it with dilute alkali solution and deionized water respectively, and dry it with nitrogen gas. The treated and activated foamed copper is used as the cathode, and two pure copper sheets of the same size are used as the anode, and a 200g L -1 CuSO 4` 5H 2 O and 60ml·L -1 H 2 SO 4 In the solution, the concentration of sodium dodecylbenzenesulfonate in the solution is 1g / L, the distance between the poles is 5cm, and the current density is 0.02A / cm 2 , 0.04A / cm 2 , 0.06A / cm 2 、0.08A / cm 2 , electroplating at room temperature for 5h, with 500r / m electromagnetic stirring during elect...

Embodiment 2

[0034] A copper foam with a thickness of 3mm and a pore size of 450μm was selected as the cathode, and the current density was 0.02A / cm 2 Next, plating for different times. The pretreatment process is the same as Example 1, inserting 200g L -1 CuSO 4` 5H 2 O and 60ml·L -1 H 2 SO 4 In the solution, the concentration of sodium dodecylbenzenesulfonate in the solution is 5g / L, the distance between the two poles is 8cm, and the current density is 0.02A / cm 2 , electroplating at room temperature for 3h, 6h, 9h, 12h, with 800r / m electromagnetic stirring during electroplating. After taking it out, rinse it with clean water and place it in an oven at 50-60°C for 0.5-1.5 hours.

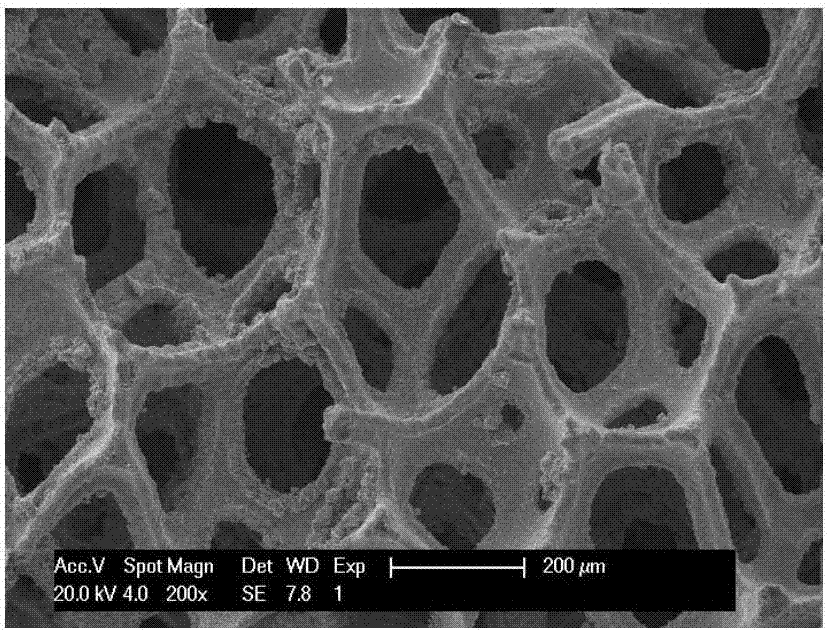

[0035] Under this current density, the microscopic morphology of copper foam electroplated for different times of 3h and 12h is as follows: Figure 5 with Image 6 shown. When electroplating for 3 hours, the plating layer is formed by the arrangement of regular-shaped individual copper particles. With ...

Embodiment 3

[0037] A copper foam with a thickness of 5mm and a pore size of 450μm was selected as the cathode, and the current density was 0.06A / cm 2 Next, plating for different times. The pretreatment process is the same as Example 1, inserting 200g L -1 CuSO 4` 5H 2 O and 60ml·L -1 H 2 SO 4 In the solution, the concentration of sodium dodecylbenzenesulfonate in the solution is 10g / L, the distance between the two poles is 10cm, and the current density is 0.06A / cm 2 , electroplating at room temperature for 3h, 6h, 9h, 12h, with 1000r / m electromagnetic stirring during electroplating. After taking it out, rinse it with clean water and place it in an oven at 50-60°C for 0.5-1.5 hours.

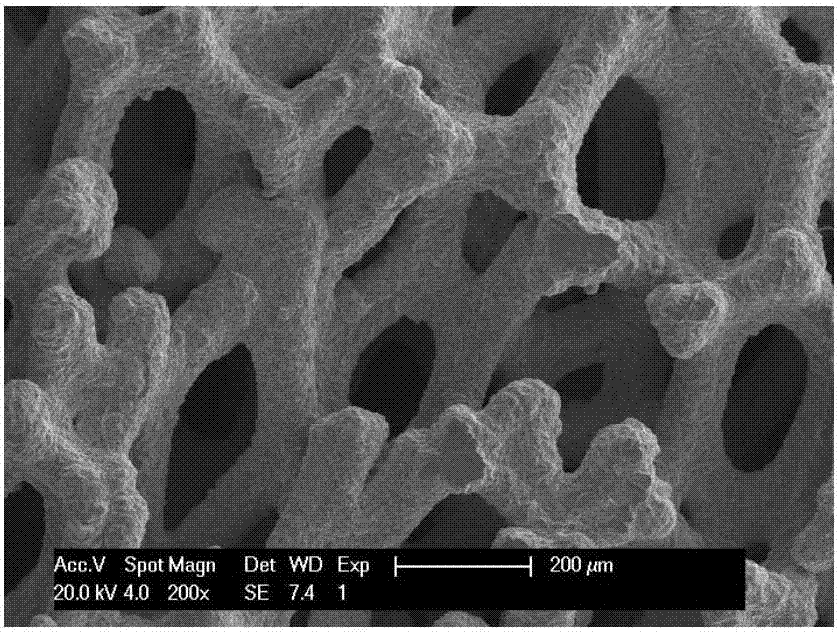

[0038] Under high current density, the microscopic morphology of copper foam electroplated for different time 3h and 12h is as follows Figure 8 with Figure 9 shown. Under the condition of constant plating time, high current density has a greater effect on reducing the aperture than low current den...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com