Extrusion-type interelectrode sulfuration forming and encapsulating method for researching flexible sensor sensitive element

A sensitive unit, vulcanization molding technology, applied in the field of sensors, can solve the problems of difficult precise control of film thickness and uniformity, high contact resistance of sensitive units, concentric distribution of films, etc., to avoid uneven thickness, uniform thickness, good The effect of adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

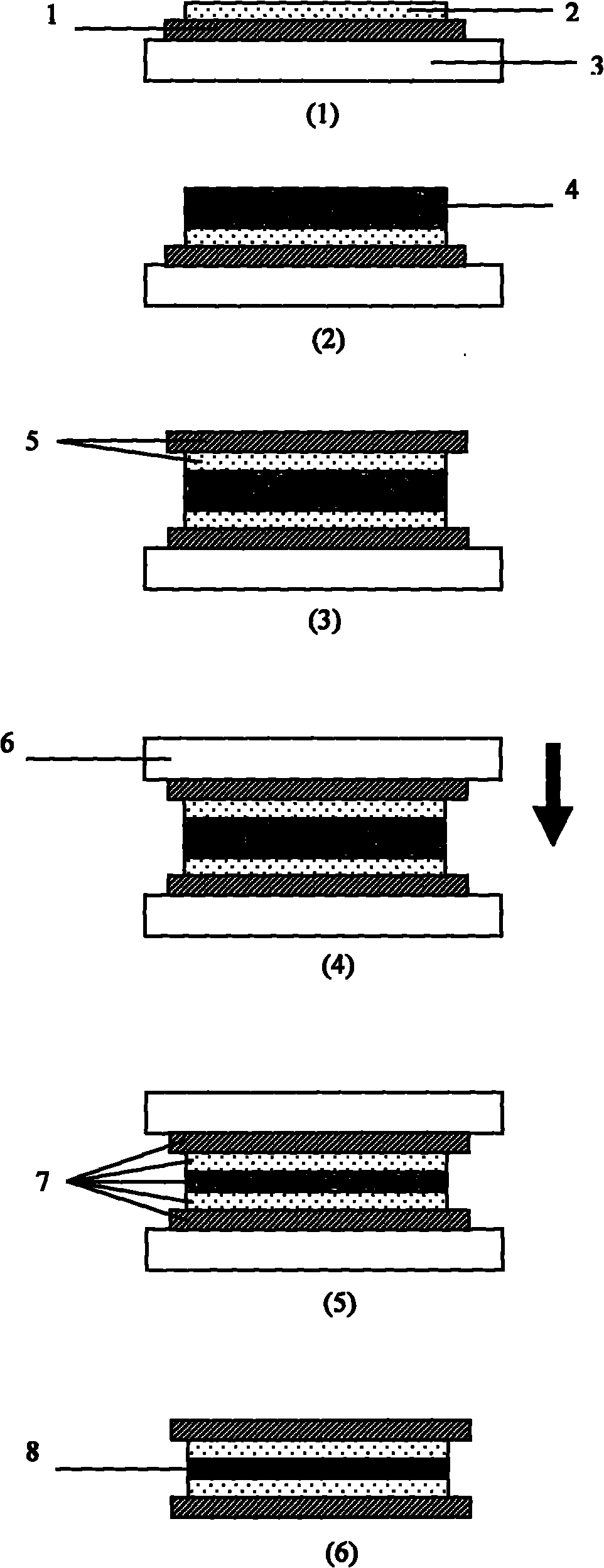

Image

Examples

Embodiment 1

[0025] A. Fix the polyimide film covered with copper foil electrodes on the lower platform of the microcomputer-controlled lifting platform for standby.

[0026] B. Dry single-walled carbon nanotubes with an inner diameter of less than 3 nanometers.

[0027] C. Mix single-walled carbon nanotubes and polydimethylsiloxane at a mass ratio of 0.02:1, and then add n-hexane organic solvent to the single-walled carbon nanotube / polydimethylsiloxane mixture, The volume ratio is 1:40.

[0028] D. Perform high-power mechanical stirring on the mixed solution of single-walled carbon nanotubes / n-hexane / polydimethylsiloxane, supplemented by ultrasonic oscillation, so that the single-walled carbon nanotubes are dispersed in the mixed solution at a temperature of 50 degrees. After the n-hexane is completely volatilized, a single-walled carbon nanotube / polydimethylsiloxane mixture is formed.

[0029] E. Mix the n-hexane and the single-walled carbon nanotube / polydimethylsiloxane mixture at a volume rat...

Embodiment 2

[0035] A. Fix the polyimide film covered with copper foil electrodes on the lower platform of the microcomputer controlled lifting platform for standby.

[0036] B. The contrast surface area is greater than 700m 2 / g of conductive carbon black powder is dried.

[0037] C. Mix the conductive carbon black powder and polydimethylsiloxane at a mass ratio of 0.08:1, and then add n-hexane organic solvent to the carbon black / polydimethylsiloxane mixture with a volume ratio of 1 : 40.

[0038] D. Perform high-power mechanical stirring on the carbon black / n-hexane / polydimethylsiloxane mixed solution, and at the same time assist with ultrasonic oscillation, to disperse the carbon black in the mixed solution at a temperature of 50 degrees, after the n-hexane is completely volatilized , To form a carbon black / polydimethylsiloxane mixture.

[0039] E. Mix the n-hexane and the carbon black / polydimethylsiloxane mixture at a volume ratio of 40:1, and repeat step D.

[0040] F. Repeat step E four time...

Embodiment 3

[0045] A. Fix the polyimide film covered with copper foil electrodes on the lower platform of the microcomputer-controlled lifting platform for standby.

[0046] B. Drying the multi-walled carbon nanotubes with an aspect ratio of 50.

[0047] C. Mix the multi-walled carbon nanotubes and polydimethylsiloxane at a mass ratio of 0.04:1, and then add n-hexane organic solvent to the multi-walled carbon nanotube / polydimethylsiloxane mixture, The volume ratio is 1:40.

[0048] D. Perform high-power mechanical stirring on the mixed solution of multi-walled carbon nanotubes / n-hexane / polydimethylsiloxane, supplemented by ultrasonic vibration, to disperse the multi-walled carbon nanotubes in the mixed solution at a temperature of 50 degrees. After the n-hexane is completely volatilized, a multi-walled carbon nanotube / polydimethylsiloxane mixture is formed.

[0049] E. Mix the n-hexane and the multi-walled carbon nanotube / polydimethylsiloxane mixture at a volume ratio of 40:1, and repeat step D....

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com