Preparation method of nanofiltration membrane for intercepting nitrate and resource utilization of concentrated solution

A nanofiltration membrane and nitrate technology, applied in chemical instruments and methods, membrane technology, semi-permeable membrane separation, etc., can solve problems such as monovalent chloride ion rejection rate less than 40%, secondary pollution, etc., to improve retention efficiency , Improve flux, improve the effect of nanofiltration membrane flux

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

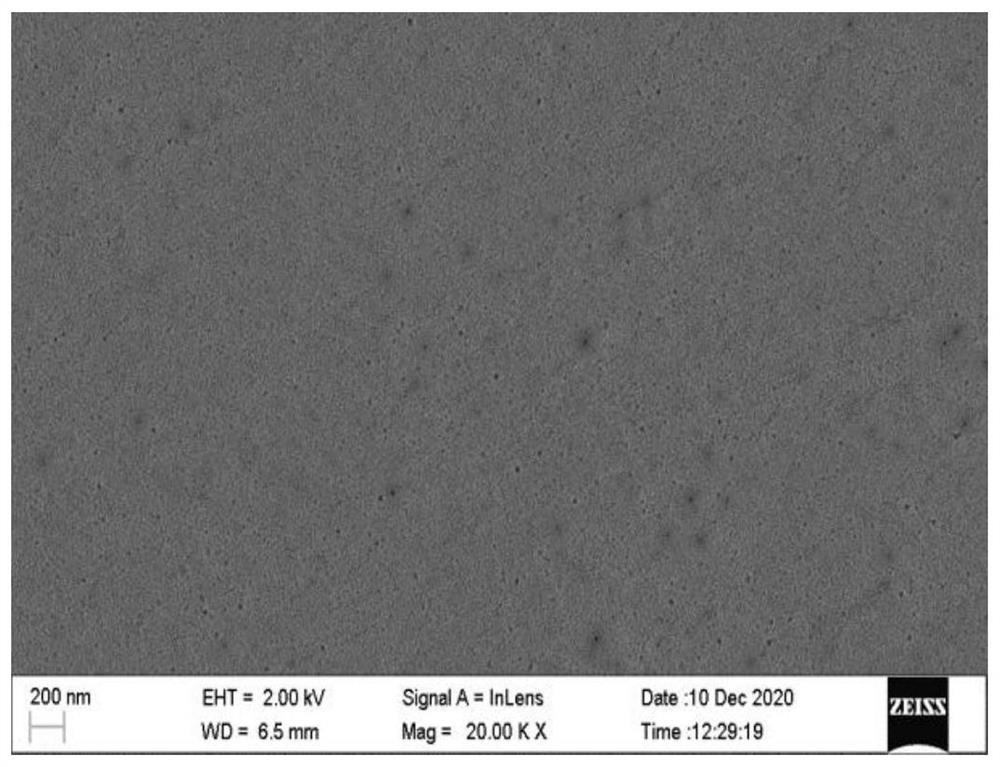

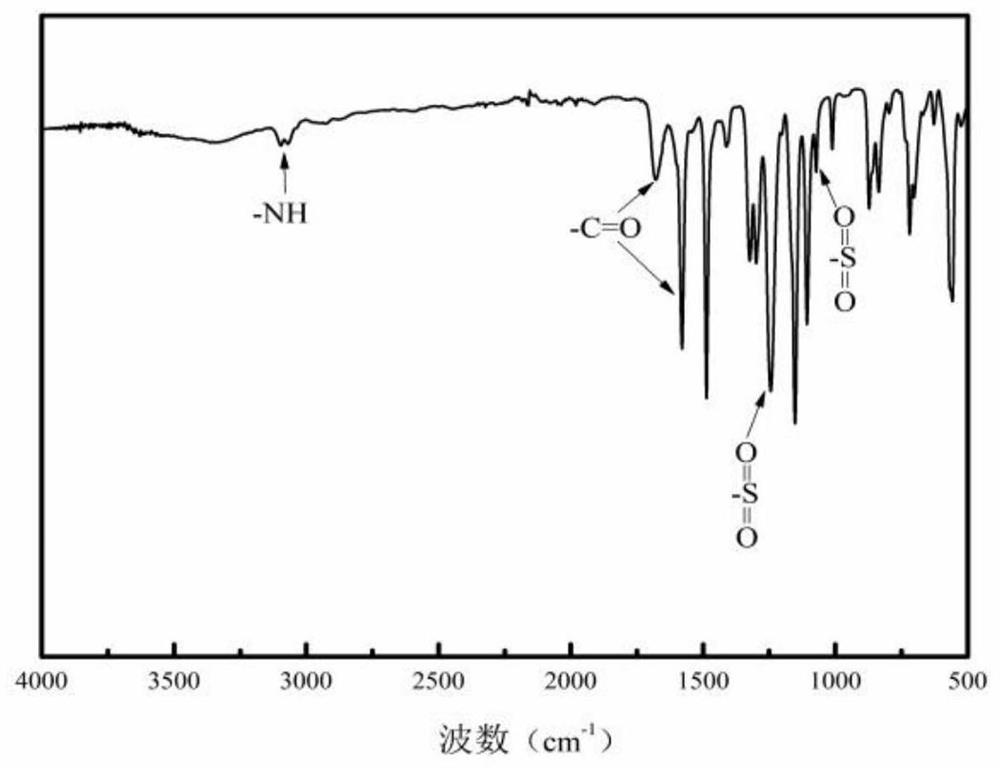

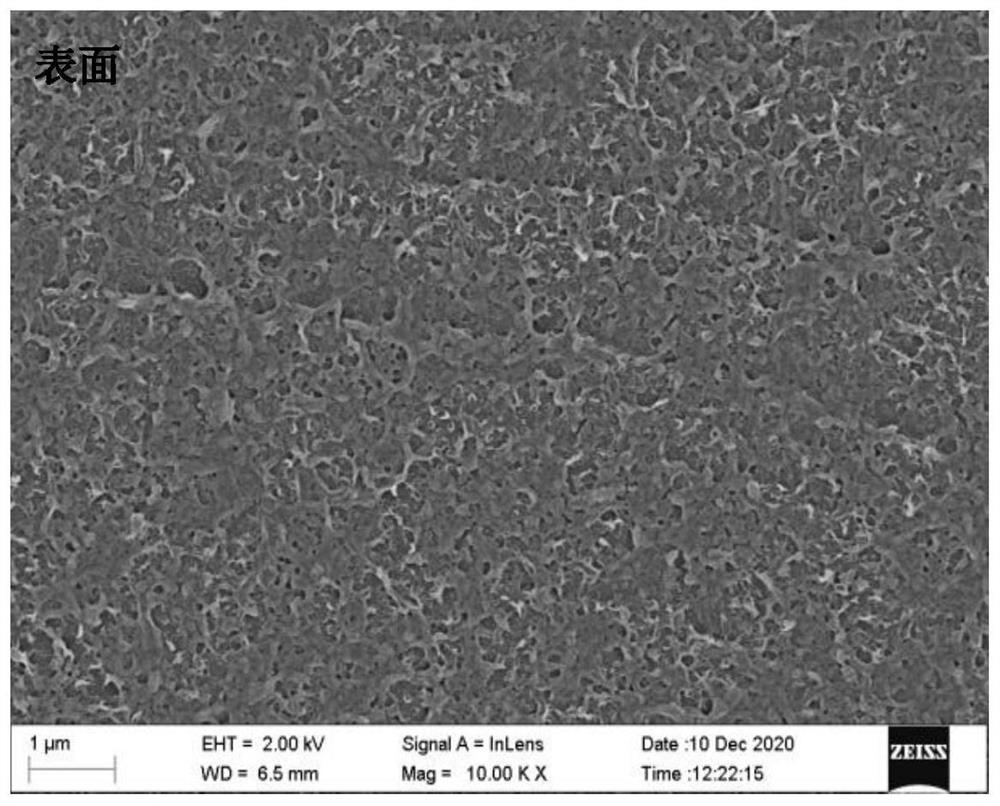

[0086] Embodiment 1 The inventive method prepares nanofiltration membrane;

[0087] S1, preparation of aqueous phase solution;

[0088] First, add 0.1g of anhydrous piperazine, 0.95g of m-phenylenediamine, and 0.95g of 2,4-diaminobenzenesulfonic acid into the beaker successively, then add 100g of deionized water into the beaker and seal it with plastic wrap, and then place it Place on a magnetic stirrer and carry out magnetic stirring, the stirring rate is 300r / min, and the stirring temperature is room temperature. After the above-mentioned raw materials are completely dissolved, 2.5g of ammonia water is added dropwise to the above-mentioned solution while stirring, and the stirring is stopped after continuing to stir for 1min. Finally, it was left to stand at room temperature for 10 minutes to eliminate possible air bubbles, and the aqueous phase solution was obtained;

[0089] S2, preparation of organic phase solution;

[0090] First 0.15g of crystalline trimesoyl chloride...

Embodiment 2

[0114] Embodiment 2 Replacement conditions The inventive method prepares nanofiltration membrane;

[0115] S1, preparation of aqueous phase solution;

[0116] Except that used medicine is 0.2g anhydrous piperazine, 0.9g m-phenylenediamine, 0.9g 2,4-diaminobenzenesulfonic acid, 2g ammoniacal liquor, other are the same as example 1, so no longer describe in detail;

[0117] S2, preparation of organic phase solution;

[0118] Same as example 1, so no more details;

[0119] S3. Preparation of polyethersulfone nanofiltration membrane with high efficiency for intercepting nitrate;

[0120] S31, aqueous phase immersion treatment of polyethersulfone base membrane;

[0121] Except that the soaking time is 5min, others are the same as Example 1, so no more detailed description;

[0122] S32, organic phase impregnation treatment;

[0123] Except that the soaking time is 3min, others are the same as Example 1, so no more detailed description;

[0124] S4. Preparation of high-through...

Embodiment 3

[0130] Embodiment 3 Replacement conditions The inventive method prepares nanofiltration membrane;

[0131] S1, preparation of aqueous phase solution;

[0132] Except that used medicine is 0.3g anhydrous piperazine, 0.85g m-phenylenediamine, 0.85g 2,4-diaminobenzenesulfonic acid, 1.5g ammoniacal liquor, others are the same as example 1, so no more detailed description;

[0133] S2, preparation of organic phase solution;

[0134] Same as example 1, so no more details;

[0135] S3. Preparation of polyethersulfone nanofiltration membrane with high efficiency for intercepting nitrate;

[0136] S31, aqueous phase immersion treatment of polyethersulfone base membrane;

[0137] Except that the soaking time is 6min, others are the same as Example 1, so no more detailed description;

[0138] S32, organic phase impregnation treatment;

[0139] Except that the soaking time is 4min, others are the same as Example 1, so no more detailed description;

[0140] S4. Preparation of high-th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| retention rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com