A kind of porous composite material modified by silane coupling olefin polymer and preparation method thereof

A porous composite material, olefin polymer technology, applied in the field of materials, can solve problems such as limited application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

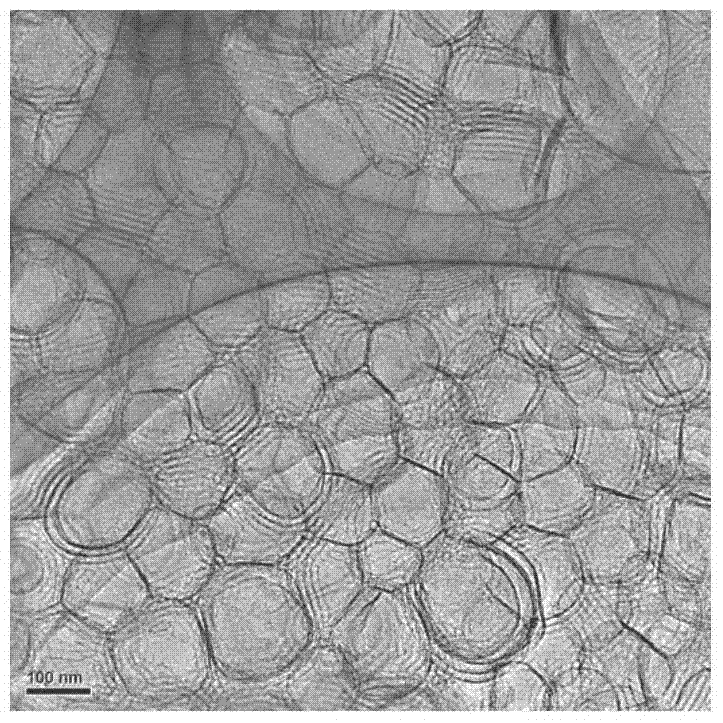

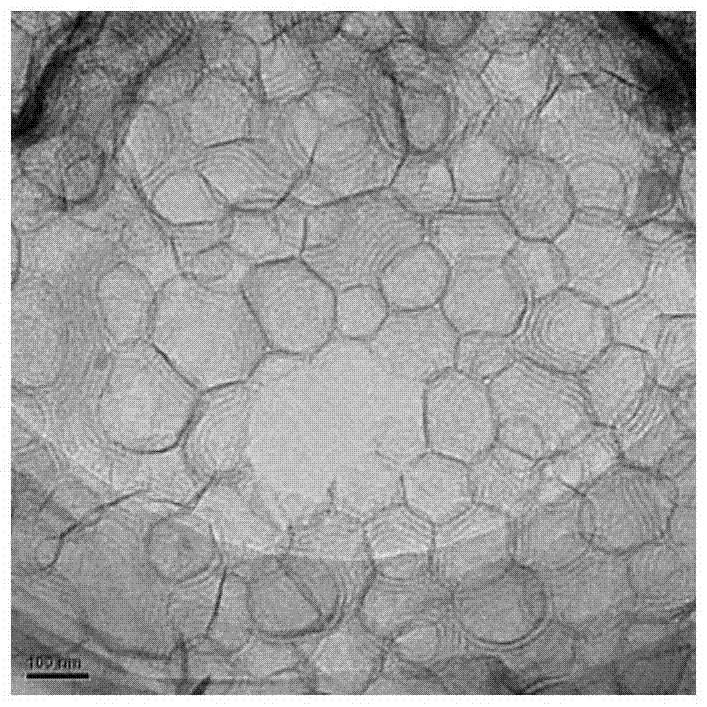

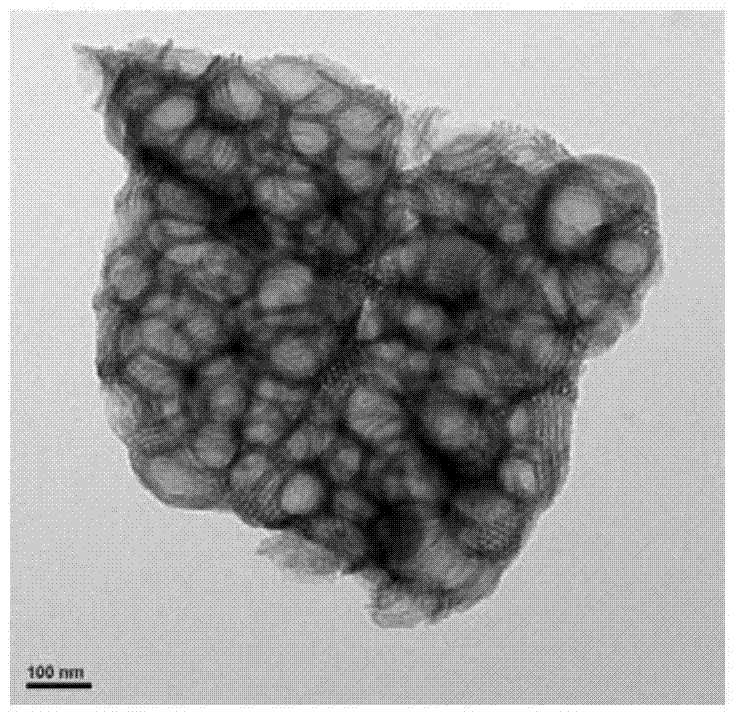

Image

Examples

Embodiment 1

[0150] 1. Synthesis of free radical initiators with silane coupling groups

[0151] First take a 500mL dry Schrank bottle and vacuumize it, replace nitrogen to remove oxygen, take 100mL dichloromethane, 17mL triethylamine and 13mL butenol into the Schrank bottle, then put the mixture in an ice-water bath at 0°C, and stir at the same time Using a separatory funnel, 12 mL of dibromoisobutyryl bromide was added dropwise. After 3 h of reaction, the ice-water bath was removed, and the mixture was stirred at room temperature for 10 h. After the reaction was completed, hydrochloric acid solution (0.1mol / L, 100mL) was added to quench, and then 100mL chloroform was added to extract twice, and the extract was then saturated with sodium bicarbonate solution (0.1mol / L, 100mL×2) and deionized water (100mL ×2) to wash, then add an appropriate amount of anhydrous magnesium sulfate to dry and filter. Finally, the obtained sample was analyzed and purified by column chromatography to obtain t...

Embodiment 2

[0163] Synthetic initiator, grafting initiator are all identical with embodiment 1.

[0164] Initiate free radical polymerization reaction in the material pores, change the ratio of each reactant, add according to the molar ratio of bromine in the vesicle material: CuBr: methyl methacrylate: PMEDTA / bpy=1:1:200:3, the reaction The process was the same as in Example 1 to obtain the second composite material. The second composite material was treated with HF, and the polymer was chemically cut out for GPC analysis. The molecular weight Mn of the polymer obtained was 31530, and the molecular weight distribution index was 1.20. The results showed that the molecular weight of the polymer increased correspondingly with the increase of the number of monomers, which indicated that the polymer was successfully grafted on the inner surface of the silicon-based vesicle material.

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com