One-pot catalytic synthesis method for interfacial polymerization of aliphatic polyamide sulfonamide

A polyamide sulfonamide and interfacial polymerization technology is applied in the field of one-pot catalytic synthesis of aliphatic polyamide sulfonamide interfacial polymerization, and can solve the problems of poor operability, low yield, complicated preparation steps and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] The synthetic procedure in Example 1. A one-pot catalytic sulfonamide fatty polyamide interfacial polymerization:

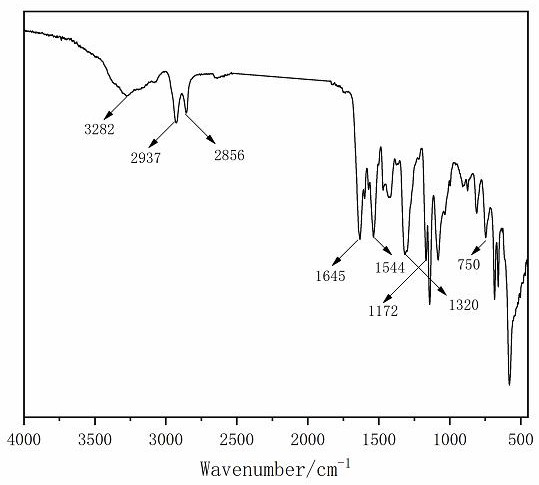

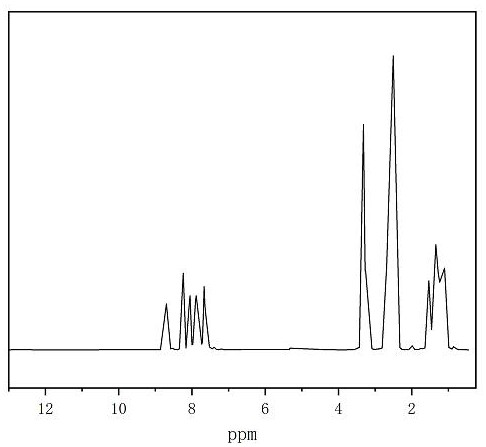

[0044] At atmospheric pressure, sufficient nitrogen, dissolved completely aliphatic diamine monomer, the composite catalyst, an acid binder deionized water was added with mechanical stirring vessel, the stirring speed of 250r / min of stirring continued dissolving an organic solvent was added dropwise a slight excess molar amount of 3-chloro-sulfonyl chloride monomers; 10 ~ 15min addition was complete, the reaction 45min at 25 deg.] C for 4h and then at 0 deg.] C, until the reaction solution PH≈7.25 when the reaction stopped, the polymer solution was precipitated white. End of the reaction, the resulting product was successively boiled deionized water and washed three times with absolute ethanol alternately, dried at 100 deg.] C under vacuum for 24 hours to obtain the sulphonamide fatty polyamide polymer, a yield of 89.53%.

[0045] Wherein: a molar ratio of 3...

Embodiment 2

[0047] Embodiment 2 A catalytic one-pot synthesis a fatty polyamide-sulfonamide interfacial polymerization:

[0048] At atmospheric pressure, sufficient nitrogen, dissolved completely aliphatic diamine monomer, the composite catalyst, an acid binder deionized water was added with mechanical stirring vessel, the stirring speed of 380r / min of stirring continued dissolving an organic solvent was added dropwise a slight excess molar amount of 3-chloro-sulfonyl chloride monomers; 10 ~ 15min addition was complete, the reaction after the reaction for 2h 25min at 40 ℃ 5 ℃, the reaction solution to be PH≈7.25 when the reaction stopped, the polymer solution was precipitated white. End of the reaction, the resulting product was boiled successively with deionized water and ethanol and alternately washed five times, dried at 100 deg.] C under vacuum for 24 hours to obtain the sulphonamide fatty polyamide polymer, a yield of 90.81%.

[0049] Wherein: a molar ratio of 3-chloro-sulfonyl chlorid...

Embodiment 3

[0051] Embodiment 3 A catalytic one-pot synthesis of an aliphatic polyamide sulfonamide interfacial polymerization:

[0052] At atmospheric pressure, sufficient nitrogen, dissolved completely aliphatic diamine monomer, the composite catalyst, an acid binder deionized water was added with mechanical stirring vessel, the stirring speed of 300r / min of stirring continued dissolving an organic solvent was added dropwise a slight excess molar amount of 3-chloro-sulfonyl chloride monomers; 10 ~ 15min addition was complete, the reaction 35min at after 3h reaction at 2 ℃ 30 ℃, the reaction solution to be PH≈7.25 when the reaction stopped, the polymer solution was precipitated white. End of the reaction, the resulting product was successively boiled deionized water and absolute ethanol alternately washed 4 times, dried at 100 deg.] C under vacuum for 24 hours to obtain the sulphonamide fatty polyamide polymer, a yield of 92.78%.

[0053] Wherein: a molar ratio of 3-chloro-sulfonyl chlorid...

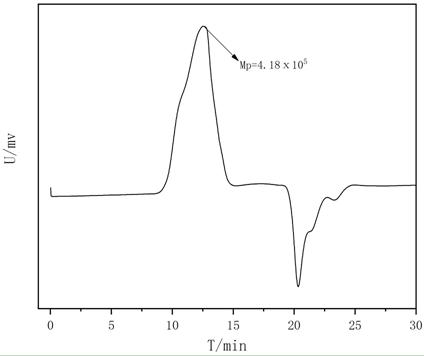

PUM

| Property | Measurement | Unit |

|---|---|---|

| friction coefficient | aaaaa | aaaaa |

| molecular weight distribution | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com