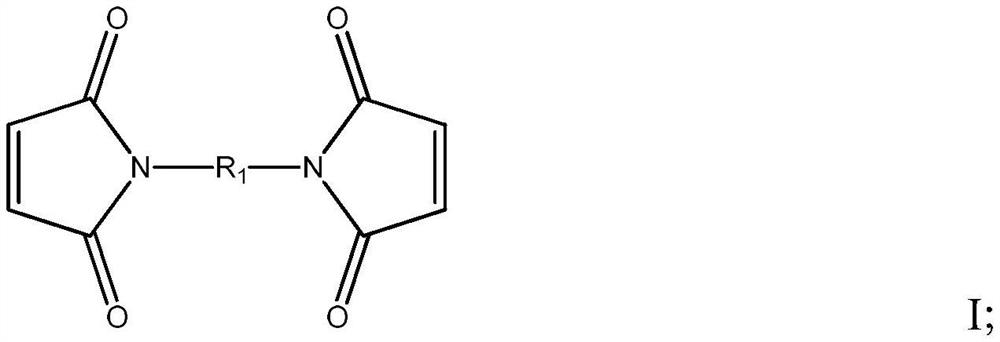

A kind of bismaleimide polymer and preparation method thereof

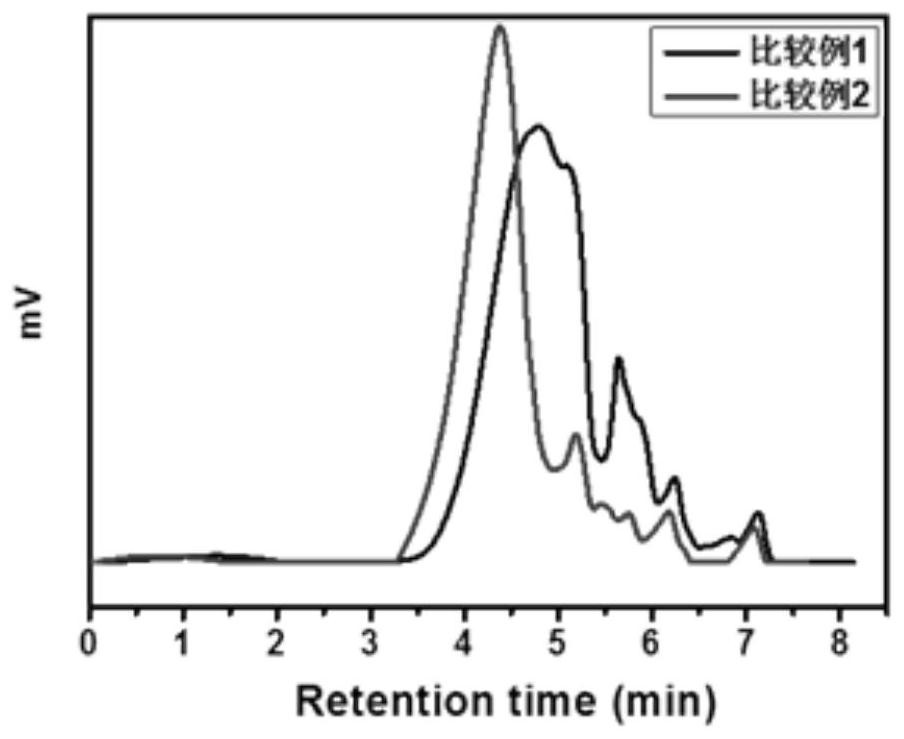

A technology of bismaleimide and polymer, which is applied in the field of bismaleimide polymer and its preparation, can solve the problems of high process cost, troublesome processing methods, and easy crosslinking of highly branched polymers. Achieve the effect of promoting application, reducing pressure and saving cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

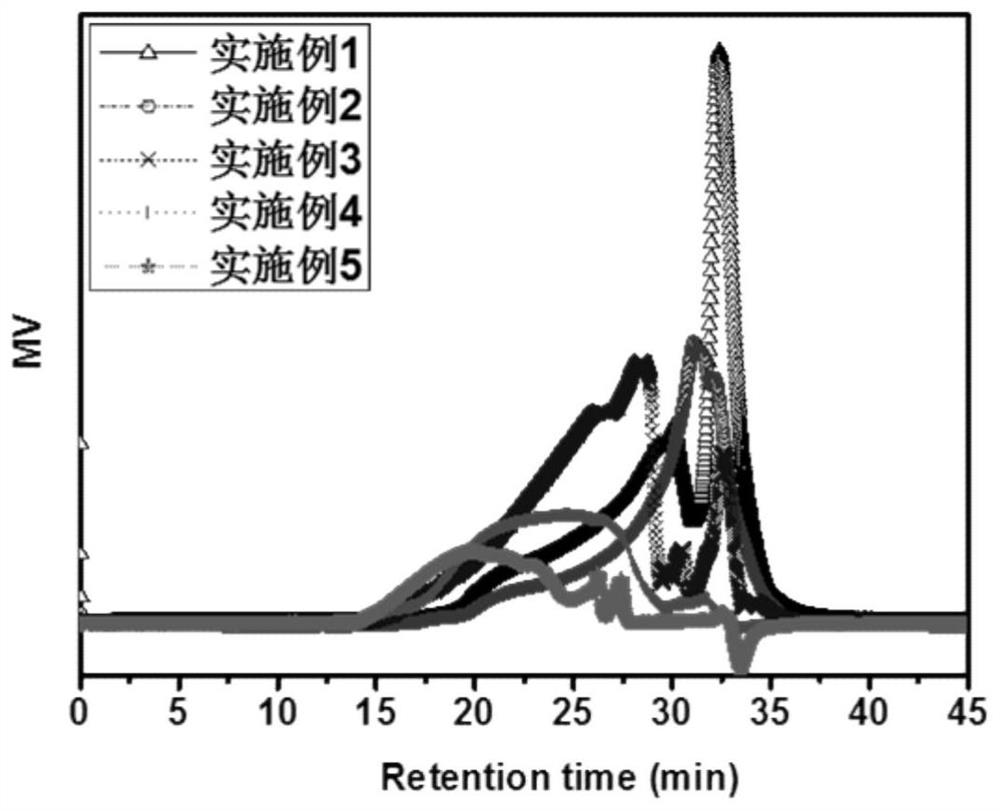

Embodiment 1

[0039] The present embodiment provides a kind of bismaleimide polymer and preparation thereof:

[0040] Put 20g of N,N'-(methylenediphenyl)bismaleimide into a 250mL three-necked flask, add 20g of γ-butyrolactone solvent and 60g of toluene, heat to 80°C, fully stir and disperse for 30min, wait After the temperature is stabilized, add 3.572g of barbituric acid powder at one time, keep stirring at 80°C for 4 hours, cool to room temperature, and separate the upper layer solvent and precipitate by wall tilting method; the obtained precipitate is washed with methanol and dried at 80°C Instantly.

Embodiment 2

[0042] The present embodiment provides a kind of bismaleimide polymer and preparation thereof:

[0043] Put 20g of N,N'-(methylenediphenyl)bismaleimide into a 250mL three-necked flask, add 60g of γ-butyrolactone solvent and 20g of toluene, heat to 80°C, fully stir and disperse for 30min, wait After the temperature is stabilized, add 3.572g of barbituric acid powder at one time, keep stirring at 80°C for 4 hours, cool to room temperature, and separate the upper layer solvent and precipitate by wall tilting method; the obtained precipitate is washed with methanol and dried at 80°C Instantly.

Embodiment 3

[0045] The present embodiment provides a kind of bismaleimide polymer and preparation thereof:

[0046] Put 20g of N,N'-(methylenediphenyl)bismaleimide into a 250mL three-necked flask, add 60g of γ-butyrolactone solvent and 20g of toluene, heat to 100°C, fully stir and disperse for 30min, wait After the temperature is stabilized, add 3.572g of barbituric acid powder at one time, keep stirring at 100°C for 4 hours, cool to room temperature, and separate the upper layer solvent and precipitate by wall tilting method; the obtained precipitate is washed with methanol and dried at 80°C Instantly.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com