Preparation method of WO3/NaSO4 composite

A composite material and mixed solution technology, applied in catalyst activation/preparation, chemical instruments and methods, chemical/physical processes, etc., can solve the problems of high photogenerated charge recombination rate, restricted photocatalytic efficiency, low conduction band potential, etc. Simple process steps, strong adsorption performance, mild reaction conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] 1) Take analytically pure ammonium metatungstate (H 28 N 6 o 41 W 12 ), using a volume ratio of absolute ethanol:isopropanol=1:1 mixed alcohol to prepare 0.08mol / L solution A;

[0025] 2) in solution A, add analytical grade sodium lauryl sulfate (C 12 h 25 SO 4 Na) magnetic stirring is even, the ratio of the amount of substance that obtains sodium lauryl sulfate and ammonium metatungstate is 0.5: 1 mixed solution B;

[0026] 3) Pour the mixed solution B into a polytetrafluoroethylene-lined high-pressure reactor at a volume filling ratio of 40%, put the sealed reactor into a homogeneous hydrothermal reactor, and react at 160°C for 24 hours;

[0027] 4) After the reaction was completed, the furnace was cooled to room temperature, the final reactant was centrifuged and washed 3 times with absolute ethanol, and the centrifuged material was oven-dried at 50°C for 4 hours to obtain WO 3 / NaSO 4 composite material.

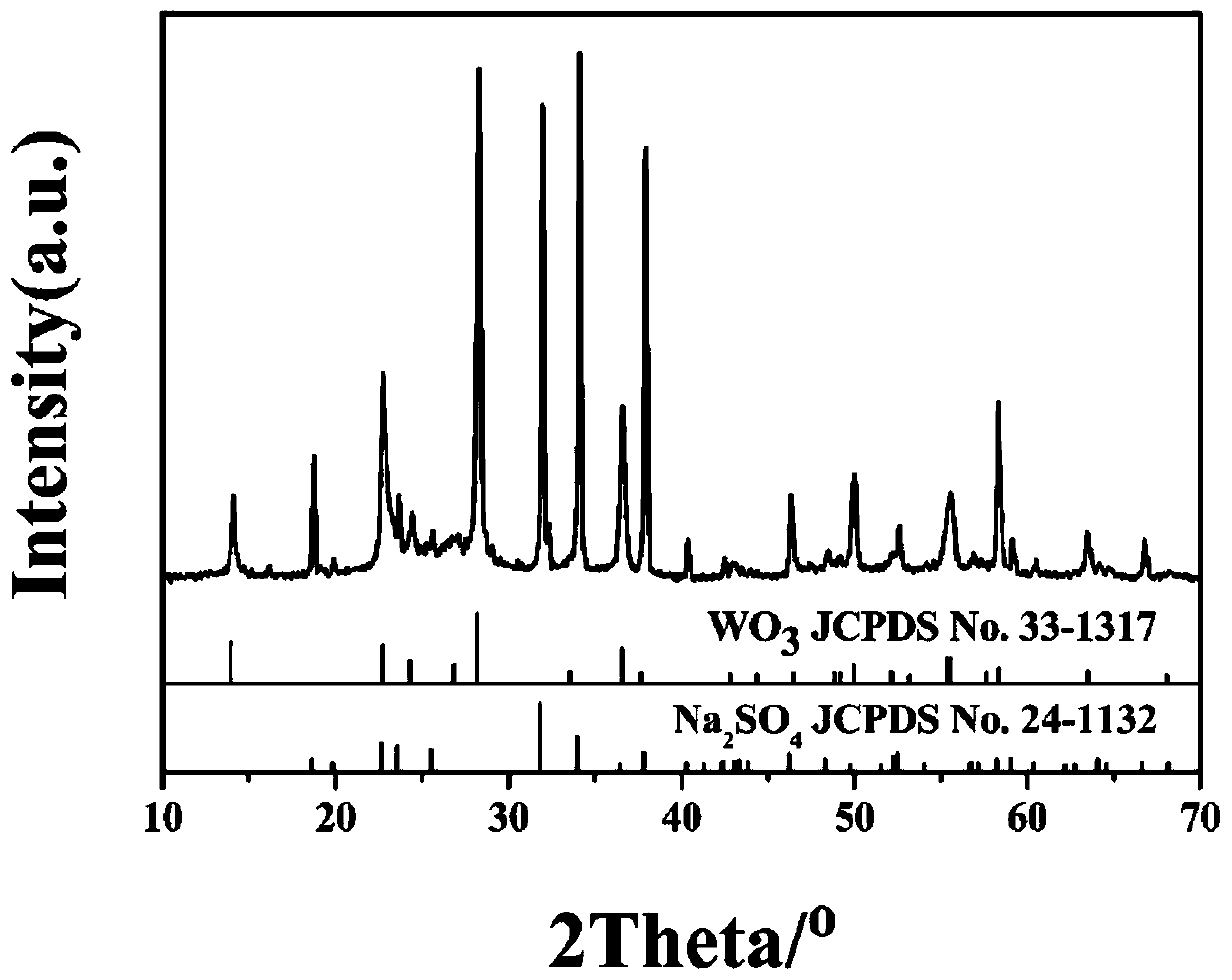

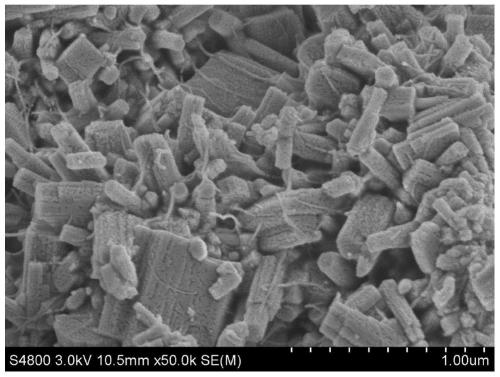

[0028] The obtained rod-shaped WO with nanowires ev...

Embodiment 2

[0032] 1) Take analytically pure ammonium metatungstate (H 28 N 6 o 41 W 12 ), use a volume ratio of absolute ethanol:isopropanol=1:0.5 mixed alcohol to prepare 0.05mol / L solution A;

[0033] 2) in solution A, add analytical grade sodium lauryl sulfate (C 12 h 25 SO 4 Na) magnetic stirring is even, the ratio of the amount of substance that obtains sodium lauryl sulfate and ammonium metatungstate is 0.3: 1 mixed solution B;

[0034] 3) Pour the mixed solution B into a polytetrafluoroethylene-lined high-pressure reactor at a volume filling ratio of 60%, put the sealed reactor into a homogeneous hydrothermal reactor, and react at 150°C for 12 hours;

[0035] 4) After the reaction was completed, the furnace was cooled to room temperature, the final reactant was centrifuged and washed 3 times with absolute ethanol, and the centrifuged material was dried in an oven at 40°C for 6 hours to obtain WO 3 / NaSO 4 composite material.

[0036] Uniformly distributed linear WO obtain...

Embodiment 3

[0038] 1) Take analytically pure ammonium metatungstate (H 28 N 6 o 41 W 12 ), using a mixed alcohol with a volume ratio of absolute ethanol:isopropanol=1:2 to prepare a 1mol / L solution A;

[0039] 2) in solution A, add analytical grade sodium lauryl sulfate (C 12 h 25 SO 4 Na) magnetic stirring is even, the ratio of the amount of substance that obtains sodium lauryl sulfate and ammonium metatungstate is 0.8: 1 mixed solution B;

[0040] 3) Pour the mixed solution B into a polytetrafluoroethylene-lined high-pressure reactor at a volume filling ratio of 30%, put the sealed reactor into a homogeneous hydrothermal reactor, and react at 140°C for 28 hours;

[0041] 4) After the reaction was completed, it was cooled to room temperature with the furnace, and the final reactant was centrifuged and washed 3 times with absolute ethanol, and the centrifuged material was dried in an oven at 60°C for 3 hours to obtain WO 3 / NaSO 4 composite material.

[0042] The evenly distribut...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com