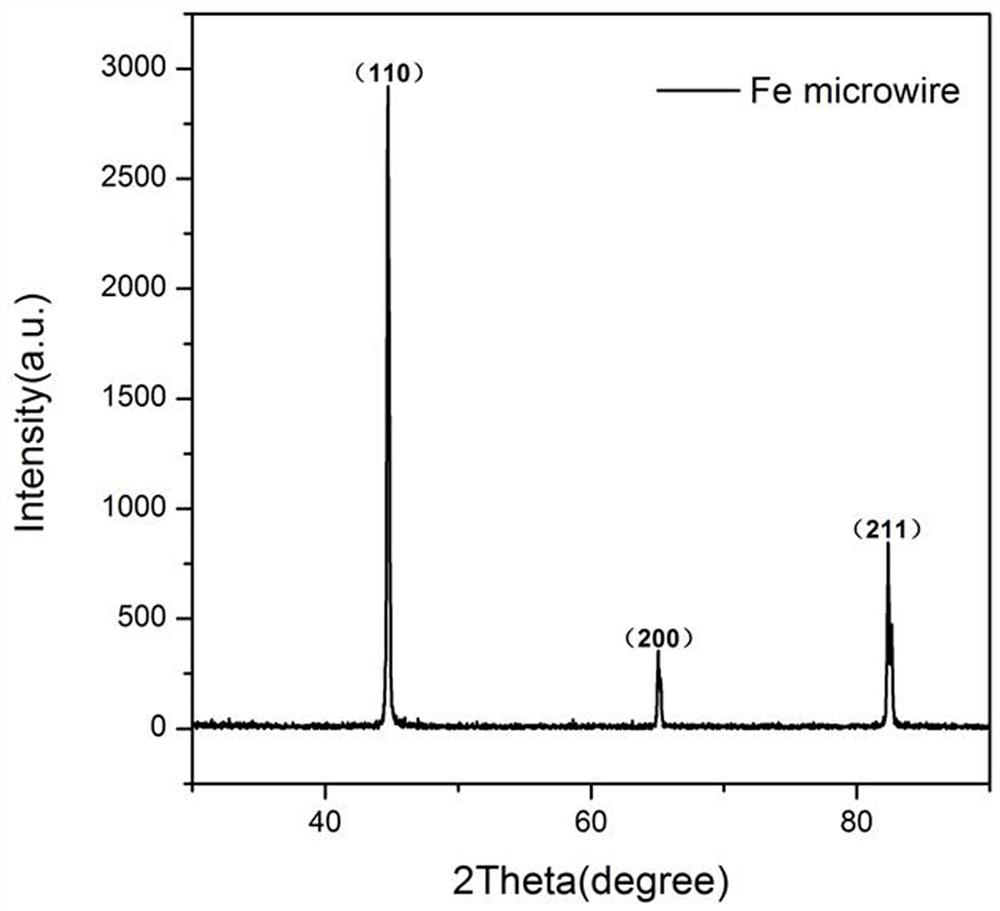

A kind of soft magnetic metal iron porous micro-wire and preparation method thereof

A technology of soft magnetic metals and micron wires, applied in the manufacture of inductors/transformers/magnets, magnetic objects, magnetic materials, etc., to achieve the effects of simple preparation process, low coercive force, and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0052] Described a kind of soft magnetic metal iron microwire with porous structure, its preparation step is as follows:

[0053] (1) Dissolve sodium hydroxide in isopropanol at room temperature to prepare a sodium hydroxide solution with a concentration of 1.4 mol / L.

[0054] (2) adding pyromellitic acid to the solution in step (1) and mixing well. The concentration of pyromellitic acid was 0.03 mol / L.

[0055] (3) At room temperature, isopropanol dissolves ferrous sulfate heptahydrate, and prepares a ferrous sulfate heptahydrate solution with a concentration of 0.01 mol / L.

[0056] (4) Add the solution of step (3) to the solution of step (2) and mix well.

[0057] (5) Add cetyltrimethylammonium bromide to the solution in step (4), and mix well. The concentration of cetyltrimethylammonium bromide was 0.01 mol / L.

[0058] (6) Add hydrazine hydrate to the solution in step (5) and mix well. The concentration of hydrazine hydrate was 1.9 mol / L.

[0059] (7) The solution in ...

Embodiment 2

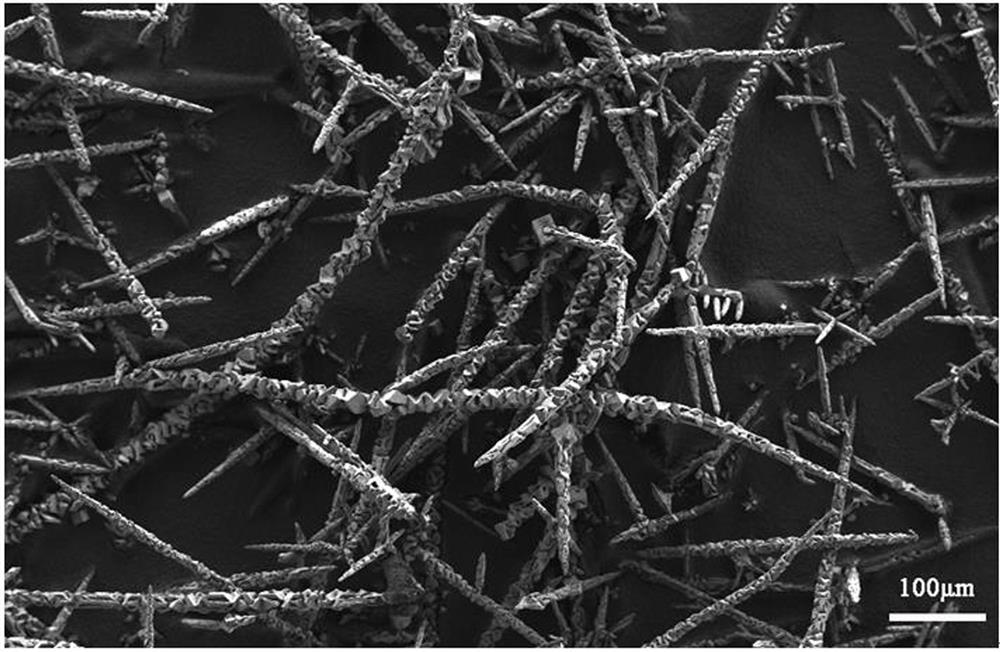

[0066] The difference from Example 1 is that the concentration of ferrous sulfate heptahydrate is 0.02 mol / L, the solvothermal reaction temperature is 180°C, and the solvothermal reaction time is 12h. Its microstructure is Image 6 shown.

[0067] from Image 6 It can be seen that the prepared iron microwires are grown from iron particles, have a porous structure, and the pores are uniformly distributed in the iron microwires. Its length is about 650 μm, its diameter is about 18 μm, and its pore size is about 3-5 μm.

Embodiment 3

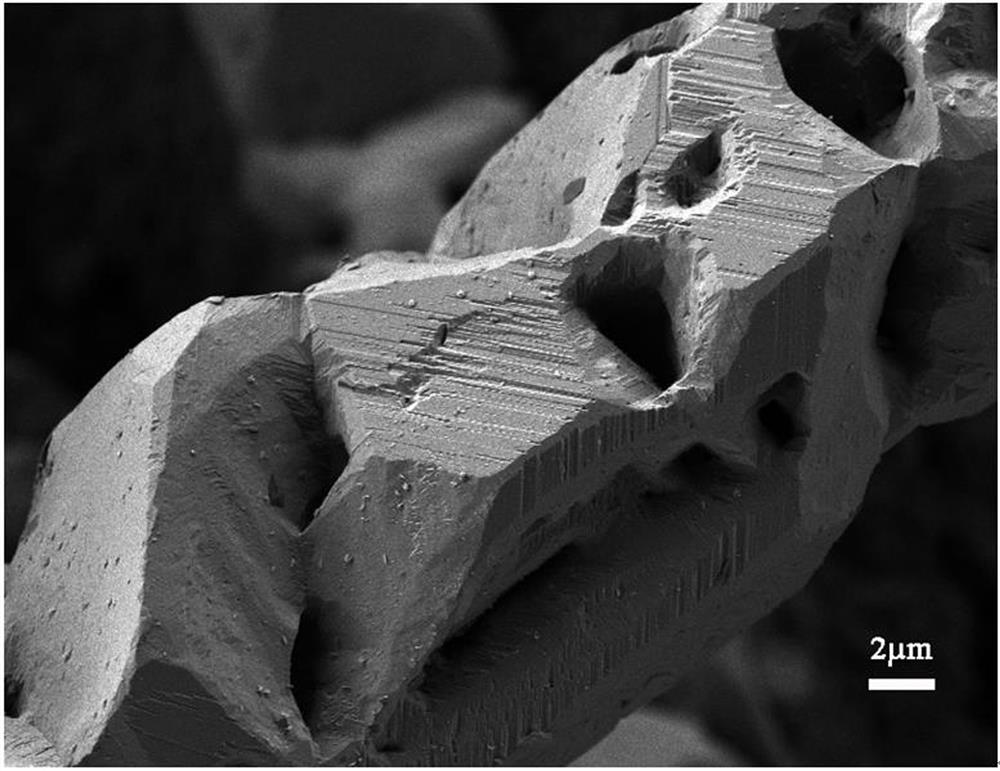

[0069] The difference from Example 1 is that the solvent is absolute ethanol, the concentration of sodium hydroxide is 1.8 mol / L, the ligand is sodium citrate dihydrate, the solvothermal reaction temperature is 180°C, and the solvothermal reaction time is 12h. Its microstructure is Figure 7 shown.

[0070] from Figure 7 It can be seen that the prepared iron microwires are grown from iron particles, have a porous structure, and the pores are uniformly distributed in the iron microwires. Its length is about 60 μm, its diameter is about 8 μm, and its pore size is about 1-2 μm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com