Rapid preparation method of LaB6 polycrystalline bulk cathode material

A cathode material and crystal block technology, which is applied in the field of rare earth boride cathode materials, can solve problems such as poor mechanical properties and emission properties of products, unfavorable large-scale industrial production and application, and complicated nano-powder preparation process, etc., to achieve large-scale Industrial production, improved mechanical and emission properties, and short sintering time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0013] LaB 6 The powder is loaded into a graphite mold, and after being pressurized and compacted, it is put into an SPS sintering furnace for sintering. The sintering process is as follows: the axial pressure is 30MPa, the atmosphere is high-purity argon gas (purity 99.999%), and the temperature is increased at 90°C / min. The rate of temperature rise, the sintering temperature is 1400 ° C, the holding time is 20 min, and the furnace is cooled to room temperature to obtain LaB 6 Polycrystalline bulk.

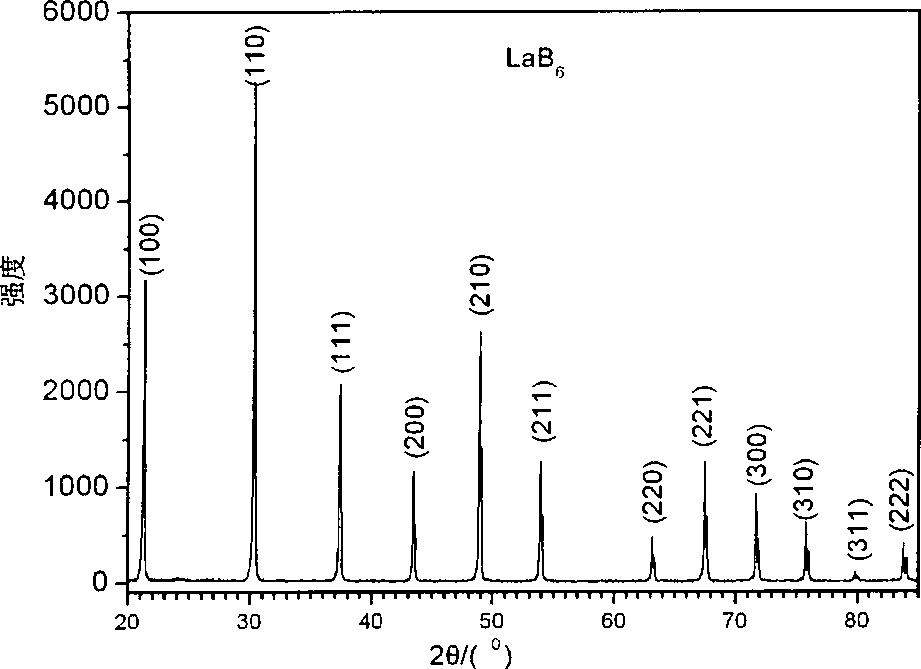

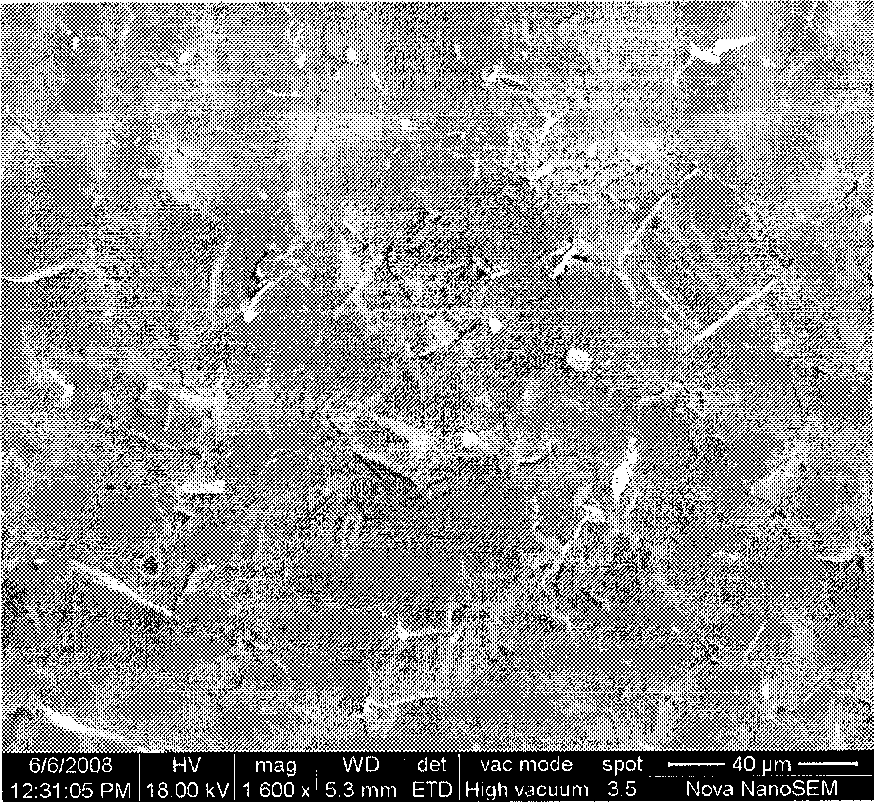

[0014] from figure 1 It can be seen that the sintered bulk crystallizes well and is LaB 6 Single phase structure. from figure 2 It can be seen that LaB 6 The grains are uniform, and the fracture mode of the sample is transgranular fracture, which helps to increase the flexural strength of the sample. The relative density of the sample reaches 90.5%, and the Vickers hardness reaches 1548kg / mm 2 , the flexural strength reaches 167.4MPa. The emission current density of the ...

Embodiment 2

[0016] LaB 6 The powder is put into a graphite mold, and after being pressurized and compacted, it is put into an SPS sintering furnace for sintering. The sintering process is as follows: the axial pressure is 40 MPa, the atmosphere is high-purity argon gas (purity 99.999%), and the temperature is increased at a temperature of 150°C / min. The rate of heating, the sintering temperature is 1500 ° C, the holding time is 10 min, and the furnace is cooled to room temperature to obtain LaB 6 Polycrystalline bulk.

[0017] LaB 6 The polycrystalline bulk was analyzed as LaB by X-ray diffraction 6 Single phase structure. The relative density of the sample reaches 92.6%, and the Vickers hardness reaches 1580kg / mm 2 , the flexural strength reaches 195.6MPa. The emission current density of the sample reaches 16.63A / cm at 1520℃ 2 , the work function is 2.40eV.

Embodiment 3

[0019] LaB 6 The powder is put into a graphite mold, and after being pressurized and compacted, it is put into an SPS sintering furnace for sintering. The sintering process is as follows: the axial pressure is 50MPa, the vacuum is evacuated to 5Pa, and the temperature is increased at a heating rate of 200℃ / min. The sintering temperature is 1700 ℃, the holding time is 5min, and the furnace is cooled to room temperature to obtain LaB 6 Polycrystalline bulk.

[0020] LaB 6 The polycrystalline bulk was analyzed as LaB by X-ray diffraction 6 Single phase structure. The relative density of the sample reaches 96.5%, and the Vickers hardness reaches 1720kg / mm 2 , the flexural strength reaches 203.2MPa. The emission current density of the sample reaches 16.98A / cm at 1520℃ 2 , the work function is 2.40eV.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Bending strength | aaaaa | aaaaa |

| Work function | aaaaa | aaaaa |

| Bending strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com