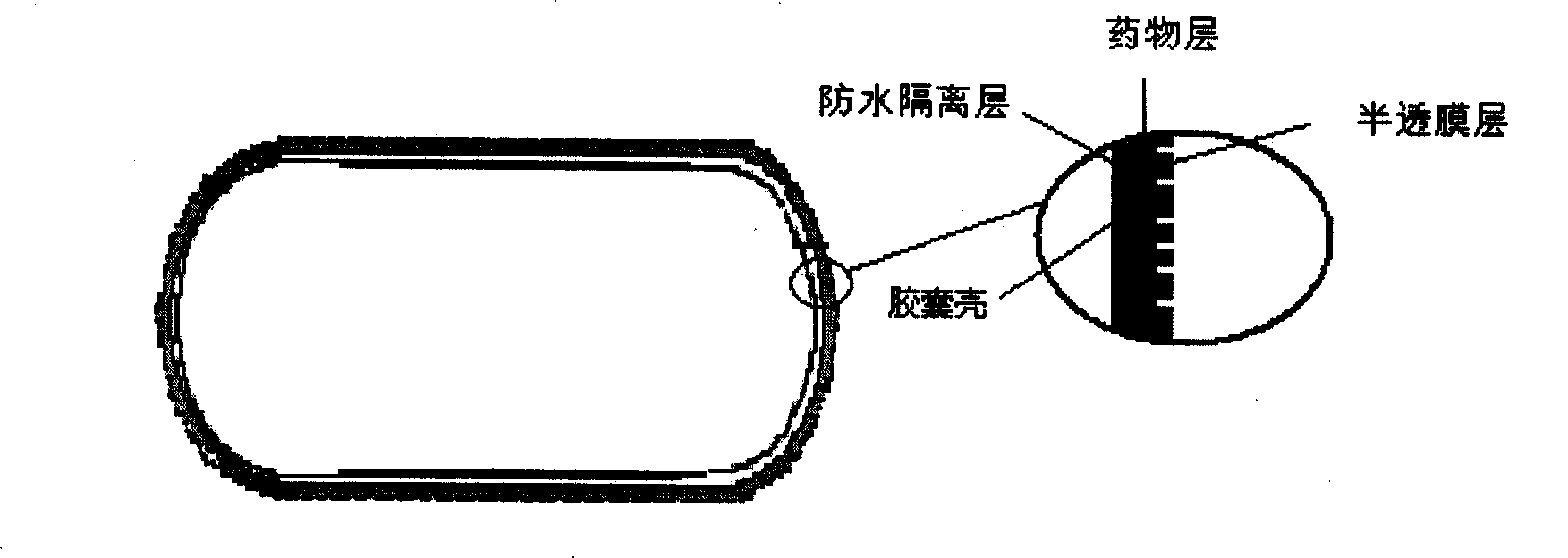

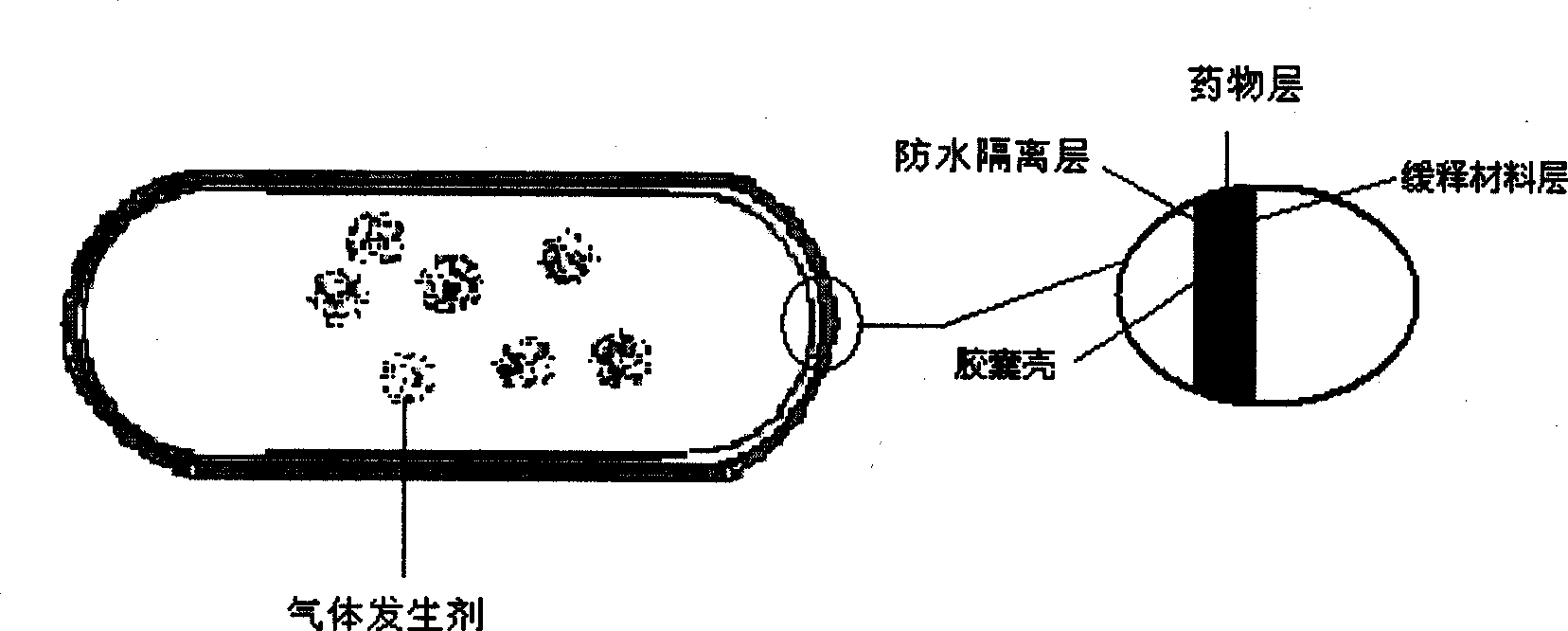

Stomach detention sustained and controlled release medicament releasing system and preparation method

A technology for controlled-release drugs and sustained-release drugs, applied in the field of medicine, can solve the problems of using many excipients, limiting flexibility, and high density of tablet cores.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0101] Air bag composition: Sustained release layer composition:

[0102] Capsule No. 1 1000 Rosiglitazone Tartrate 8g

[0103] Ethyl cellulose 9.0g Stearic acid 32g

[0104] Stearic acid 15.0g Ethyl cellulose 40g

[0105] Triethyl citrate 4.5g Povidone k30 16g

[0106] Talc powder 3.0g Polyethylene glycol 24g

[0107] Add absolute ethanol to 300ml Talc powder 16g

[0108] 90% ethanol solution to 1000ml

[0109] Process: Put the No. 1 capsule shell into the coating pan, spray the prepared waterproof coating solution (dissolved / dispersed by stearic acid, ethyl cellulose, triethyl citrate, talc powder) at a tablet bed temperature of 45°C Prepared in absolute ethanol), after the weight gain of the coating was 15%, the capsule was locked, and the weight gain of the coating was 15%, and placed at 45°C for 12h to obtain a waterproof air bag; Rosiglitazone tartrate, stearic acid , ethyl cellulose, povidone, polyethyle...

Embodiment 2

[0111] Air bag composition: Drug layer:

[0112] Capsule No. 1 1000 pcs Rosiglitazone Maleate 1.5g

[0113] Ethylcellulose 9.0g Eudragit RL100 4.5g

[0114] Stearic acid 15.0g Ethyl cellulose 2.0g

[0115] Triethyl citrate 4.5g Polyethylene glycol 1.0g

[0116] Talc powder 3.0g 90% ethanol solution 100ml

[0117] Add absolute ethanol to 300ml

[0118] Isolation layer: Controlled release coating:

[0119] Lactose 30g Eudragit RS100 2.5g

[0120] povidone k30 3.0g Ethylcellulose 2.0g

[0121] Absolute Ethanol 200ml Polyethylene Glycol 1.0g

[0122] Triethyl citrate 0.8g

[0123] 90% ethanol 100ml

[0124] Process: Put the No. 1 capsule shell into the coating pan, spray the prepared waterproof coating solution (dissolved / dispersed by stearic acid, ethyl cellulose, triethyl citrate, talc powder) at a tablet bed temperature of 45°C prepared in absolute ethanol), after the weight gain of coati...

Embodiment 3

[0126] Airbag Composition Eudragit RL100 4.5g

[0127] Waterproof layer: ethyl cellulose 2.0g

[0128] Eudragit L100 9.0g Polyethylene glycol 1.0g

[0129] Stearic acid 15.0g 90% ethanol solution 100ml

[0130] Triethyl citrate 4.5g

[0131] Talc powder 3.0g Controlled Release Coating:

[0132] Absolute ethanol to 300ml Eudragit RS100 2.5g

[0133] Ethylcellulose 2.0g

[0134] Composition of drug-containing layer: Polyethylene glycol 1.0g

[0135] Drug layer: Triethyl citrate 0.8g

[0136] Rosiglitazone Maleate 1.5g 90% Ethanol 100ml

[0137] Process: Put the No. 1 capsule shell into the coating pan, spray the prepared waterproof coating solution (dissolved / dispersed in stearic acid, Eudragit L100, triethyl citrate, talc powder in the water ethanol), after the weight gain of coating was 15%, the capsule was locked, and then the weight gain of the coating was 15%, and placed at 45°C for 12h to obtain a waterproof air bag;...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com