Accurate structure POSS hybridization low dielectric material preparation

A low-dielectric material, hybrid technology, used in plastic/resin/wax insulators, organic insulators, etc., can solve the problems of unstable material properties, difficult to control precise material structure, etc., to achieve mild reaction conditions, efficient and controllable environment , Environmentally friendly effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

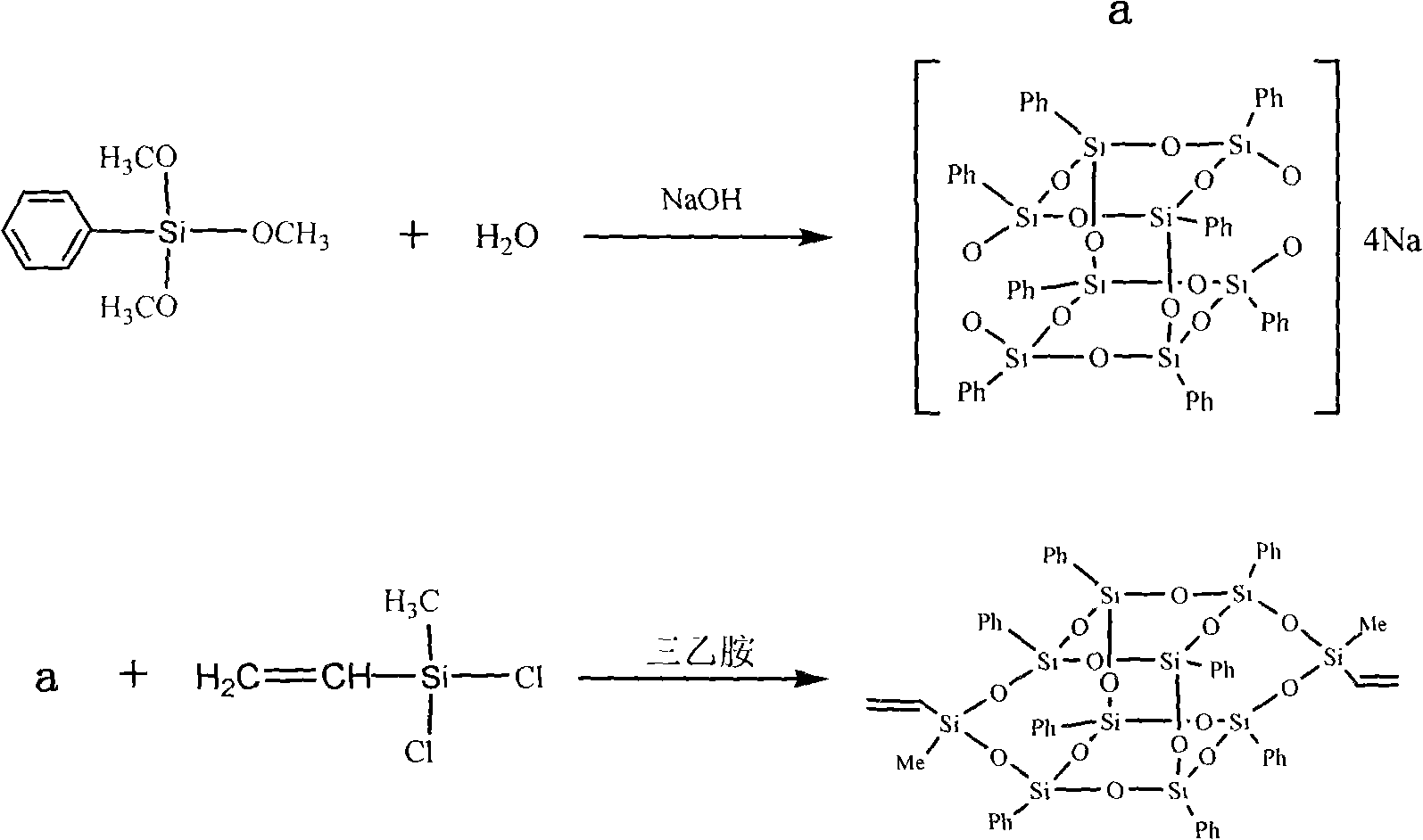

[0022] Synthesis of double-arm vinyl POSS: (1) Preparation of double-arm vinyl POSS intermediate: 120g of trimethoxyphenylsilane, 16g of NaOH and 10-20g of H 2 O is placed in a 1000mL four-neck flask equipped with a constant pressure funnel, a condensing reflux tube, and a thermometer, and then 2-propanol is added (the mass ratio of the reaction substance to 2-propanol is 1:4 to 1:40) to dissolve the above substances , under the protection of nitrogen, magnetically stirred and heated to reflux for 4h, stopped heating, left the reaction mixture at room temperature for 8h, filtered, washed with 2-propanol, and dried in vacuo to obtain a white solid a; (2) 22.60g (0.02mol) of solid a and 8.00g (0.08mol) of triethylamine were placed in a four-necked flask equipped with a condensing reflux tube, a constant pressure funnel and a thermometer, and 200-300mL of THF was added, and magnetically stirred for 1h. Add 8.40g (0.06mol) of methylvinyldichlorosilane dropwise through the funnel, ...

Embodiment 2

[0029] Synthesis of mercapto POSS: 196.30g (1.0mol) of γ-mercaptopropyltrimethoxysilane, 800mL of methanol, 55mL of distilled water and an appropriate amount of concentrated hydrochloric acid are used to adjust the pH value to 3.0, and then added to the In a 1500mL three-neck flask, under the protection of nitrogen, the reaction was carried out at a constant temperature of 60°C for 48h. Then stop heating and cool to room temperature, filter the product precipitated by the reaction, and wash the product with cyclohexane.

[0030]

[0031] Synthesis of diene monomer: Take a 1000mL flask, add 20.00g (0.144mol) p-hydroxybenzoic acid, then pour 300mL ethanol and 200mL water. Also known as 10g NaOH and 2g KI, dissolved in 100mL H 2 In O, add NaOH, KI solution to the ethanol-water solution drop by drop, after about 1~2h, add 13mL (0.153mol, excess) bromopropene, and reflux at 65~70°C for 70h. Stop the reaction, add 30mL of concentrated hydrochloric acid to acidify, rotary evapor...

Embodiment 3

[0036] The synthesis of two-arm azido-based POSS, its synthetic method is divided into 3 steps, (1) is identical with the synthetic step (1) of double-arm vinyl POSS in embodiment 1; (2) only double-arm vinyl in embodiment 1 The methylvinyldichlorosilane in the synthetic step (2) of the base POSS is replaced by 3-propylmethyldichlorosilane of 11.40g (0.06mol); (3) the substance of 26.44g (0.02mol) b was dissolved in 150mL of THF, and then added 3.90g (0.06mol) NaN 3 20mL of aqueous solution, stirred at room temperature for 2 to 6 hours, and purified to obtain double-armed azido POSS. The response is as follows:

[0037]

[0038] Synthesis of bifunctional alkyne monomer: put 8.00g (0.10mol) of acetylenic acid and 23.80g (0.20mol) of thionyl chloride in a 250mL round-bottomed flask with a condenser, heat and stir, and react at 65°C for 4h , excess SOCl was distilled off under reduced pressure 2 , and then dissolved in dichloromethane (diamine monomer and dichloromethane ma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com