Galactomannan gum got by irradiation degradation, preparation and use thereof

A technology of galactomannan and irradiation, which is applied in coatings, natural resin coatings, etc., can solve the problems of low biodegradation and chemical degradation efficiency of galactomannan gum

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

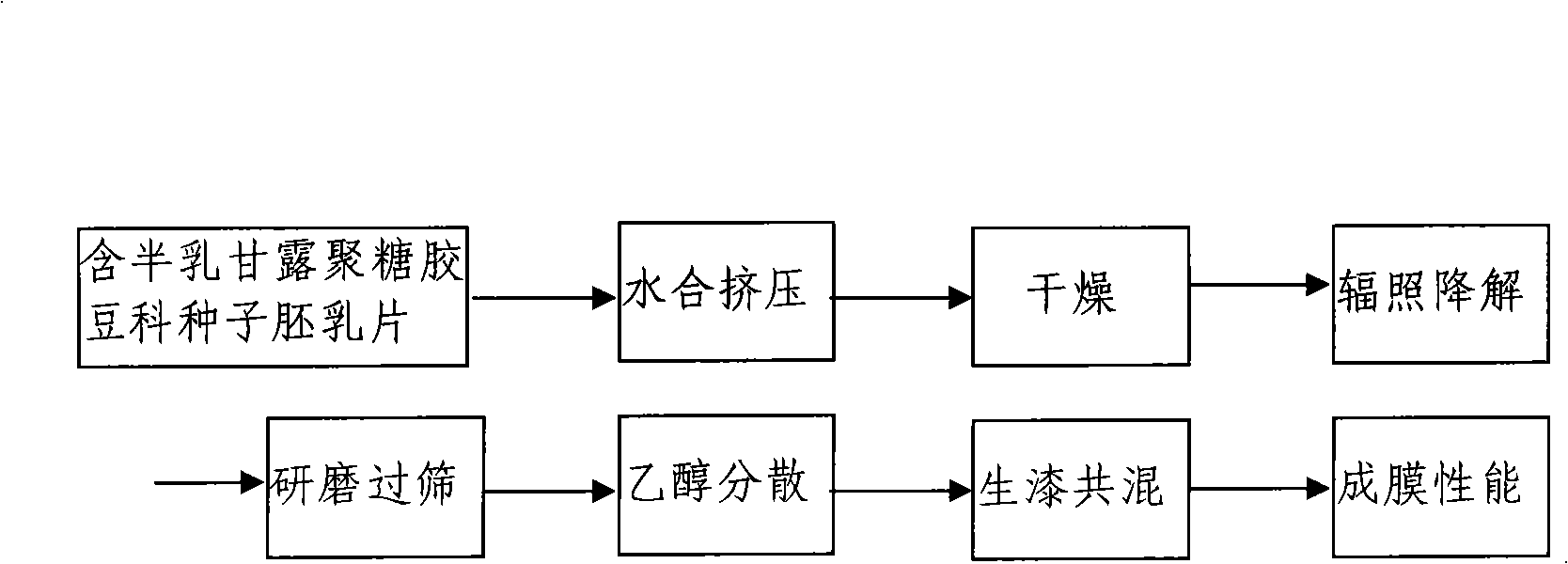

Method used

Image

Examples

Embodiment 1

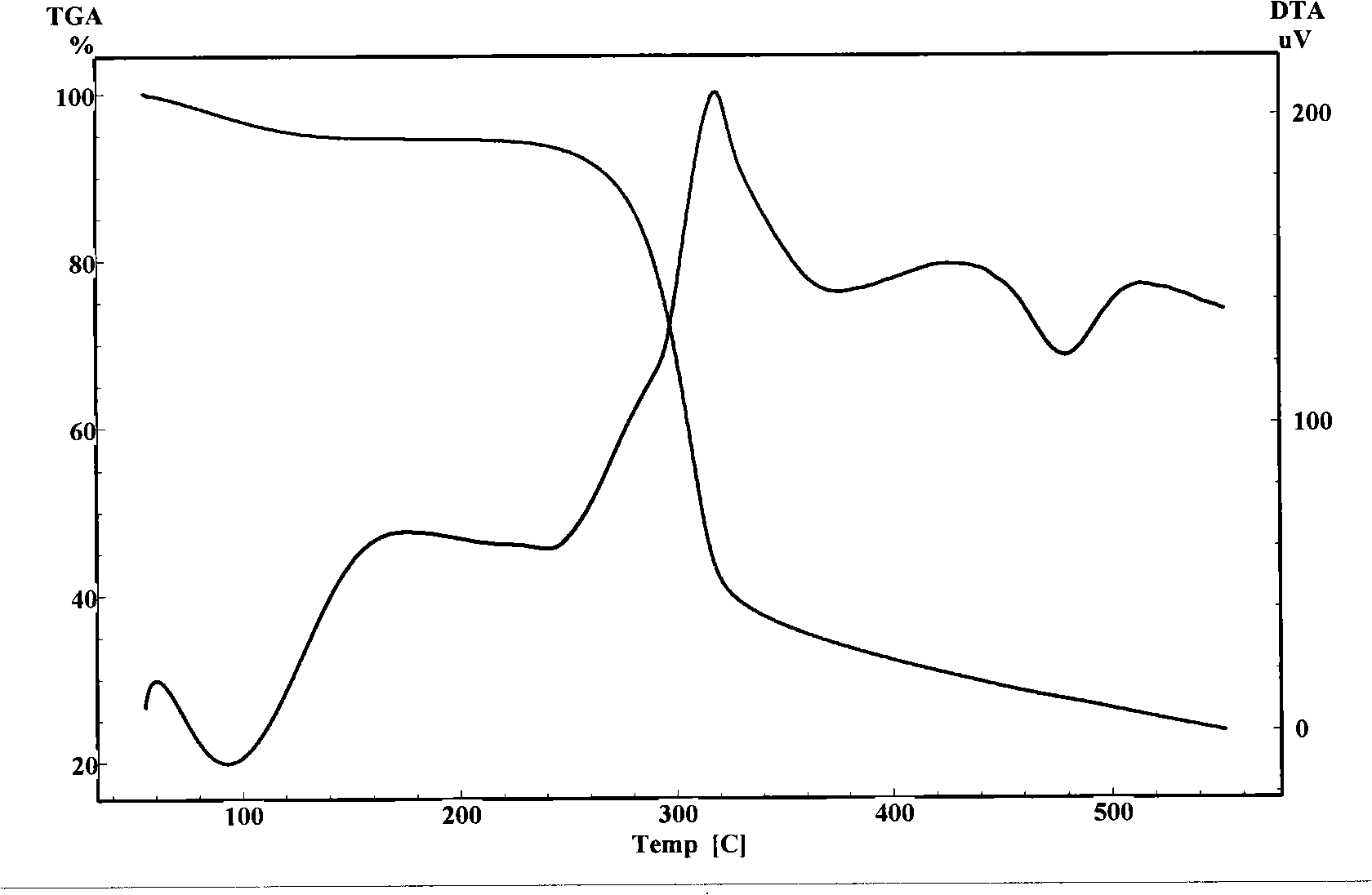

[0035] The preparation of embodiment 1 radiation degradation galactomannan gum

[0036] Acacia seed endosperm slices are hydrated, squeezed against rollers, and air-dried. The moisture content of the material is 18%. The material is put into a polyethylene plastic bag, and the bagged material is irradiated and degraded with cobalt 60-γ rays as the radiation source. , the irradiation dose is 8KGy, and then it is ground by a grinder and passed through a 500-mesh sieve to obtain radiation-degraded saponins polysaccharide gum powder. Disperse the radiation-degraded saponin locust polysaccharide gum powder in absolute ethanol at a weight ratio of 1:5, and stir for 15 minutes.

Embodiment 2

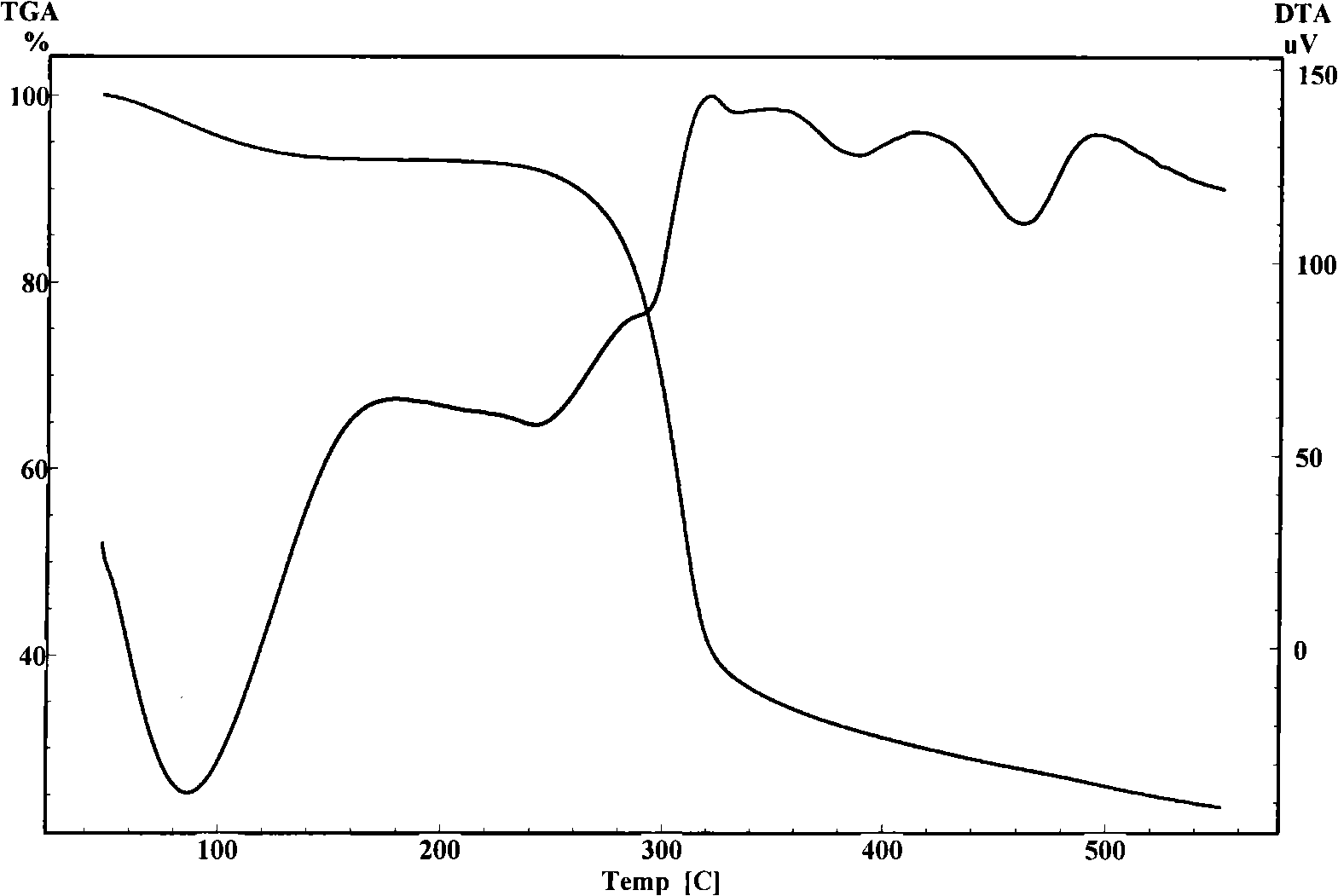

[0037] Example 2 Preparation of Radiation Degraded Galactomannan Gum

[0038] Acacia seed endosperm slices are hydrated, squeezed against rollers, and air-dried. The moisture content of the material is 21%. The material is put into a polyethylene plastic bag, and the bagged material is irradiated and degraded with cobalt 60-γ rays as the radiation source. , the irradiation dose is 7KGy, and then it is ground by a grinder and passed through a 500-mesh sieve to obtain radiation-degraded saponins polysaccharide gum powder. Disperse the radiation-degraded saponin locust polysaccharide gum powder in absolute ethanol according to the weight ratio of 1:3, and stir for 15 minutes.

Embodiment 3

[0039] Example 3 Preparation of Radiation Degraded Galactomannan Gum

[0040] The endosperm slices of Tara seeds are hydrated, squeezed on opposite rollers, and dried by air flow. The moisture content of the material is 22%. The material is put into a polyethylene plastic bag, and the bagged material is irradiated with cobalt 60-γ rays as the radiation source. Degradation, the irradiation dose is 7KGy, then through the grinder grinding and all pass through 500 mesh sieve, make radiation degradation saponins polysaccharide gum powder. Disperse the radiation-degraded acacia polysaccharide gum powder in absolute ethanol at a weight ratio of 1:8, and stir for 15 minutes.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com