Self-cleaning coating agent for construction exterior wall paint, preparation and use method

A self-cleaning technology for building exterior walls, applied to polyester coatings, devices for coating liquid on surfaces, coatings, etc., can solve problems such as complex high-temperature calcination processes, achieve stable and long-lasting dispersion effects, save costs, and increase costs Effect of Membrane Properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

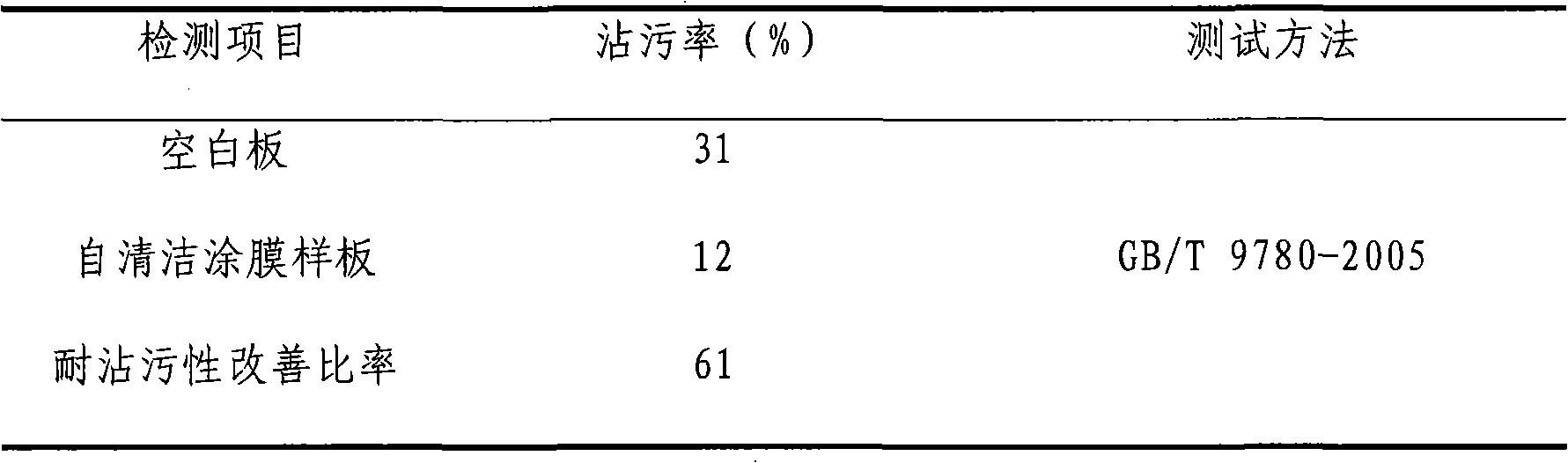

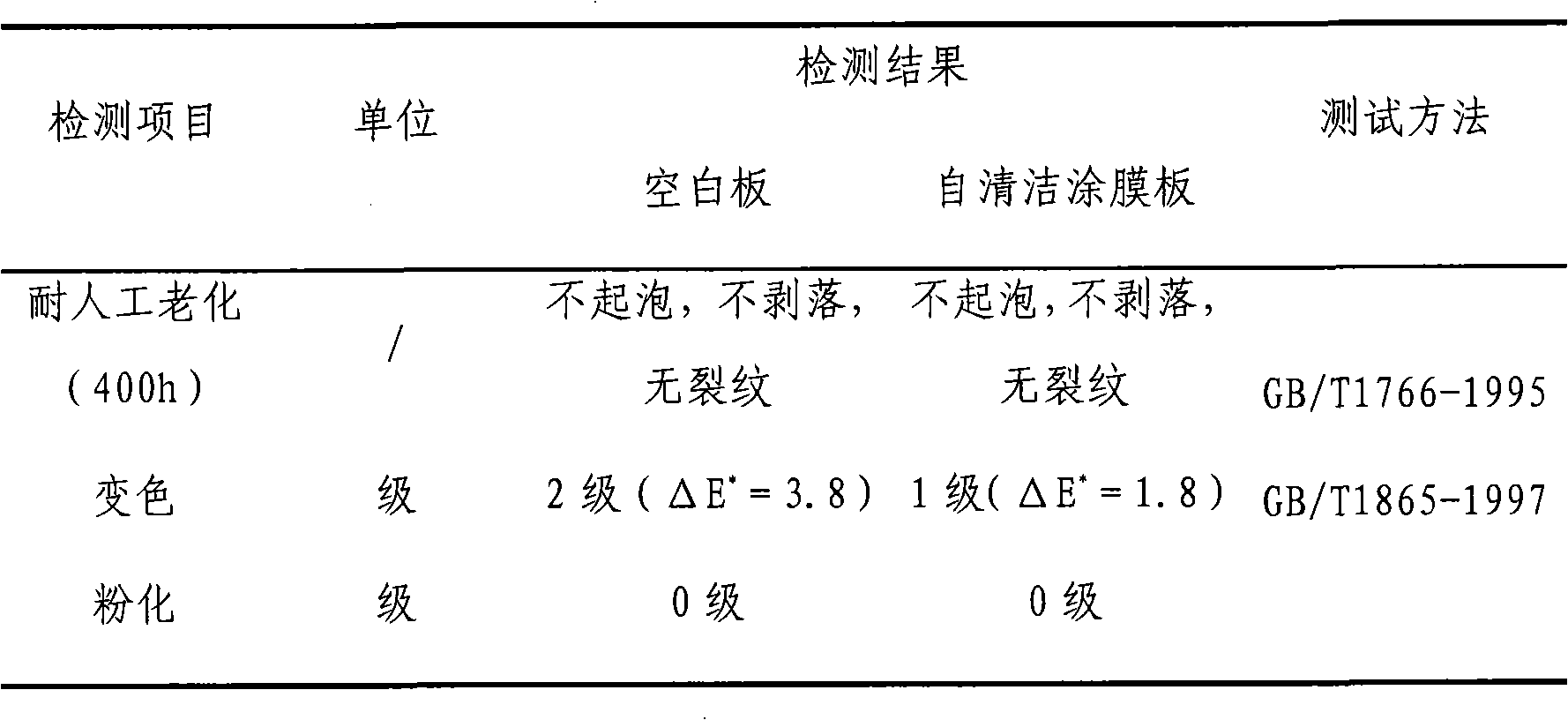

Embodiment 1

[0022] Firstly, a nano-titanium oxide composite sol with a solid content of 2% was prepared, in which the titanium oxide was in anatase crystal form and the particle diameter was less than 10 nm. 0.5% of sodium dodecylbenzenesulfonate and polyethylene glycol- The mixture of 600, wherein the mass ratio of sodium dodecyl benzene sulfonate and polyethylene glycol-600 is 3:1, is dispersed in the sodium hydroxide aqueous solution of pH=10 after vigorous stirring to form a transparent and stable dispersion. The dispersion liquid is added to the acrylic emulsion with a mass percentage of 0.3%, and the mixture is stirred evenly at normal temperature to obtain a self-cleaning functional film coating agent. The above-mentioned film coating agent is sprayed on the surface of the building exterior wall paint for secondary coating, and is naturally dried at normal temperature to form a multifunctional coating with anti-fouling, anti-ultraviolet radiation and air purification properties. Ta...

Embodiment 2

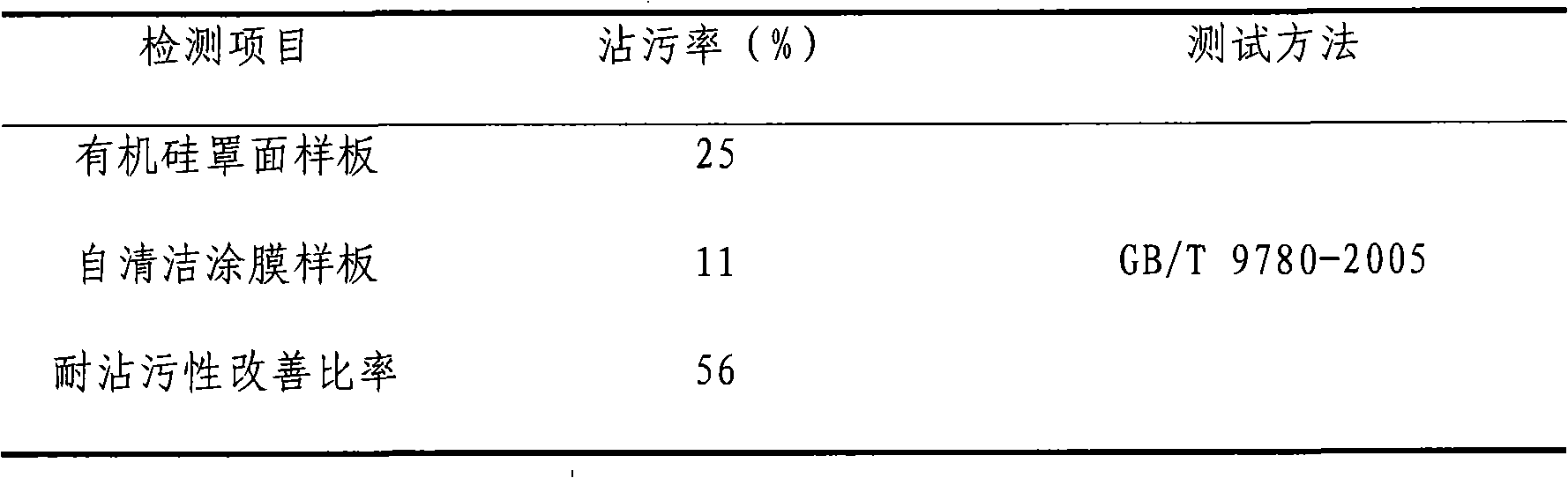

[0032] Firstly, a nano-titanium oxide composite sol with a solid content of 2% was prepared, in which the titanium oxide was anatase crystal form and the particle diameter was less than 10 nm. A mixture of 10% aliphatic alcohol polyoxyethylene ether sodium sulfate and diethanolamine was added to the sol. The ratio of fatty alcohol polyoxyethylene ether sodium sulfate and diethanolamine is 1:1, and after vigorous stirring, it is dispersed in an aqueous sodium hydroxide solution with pH=10 to form a transparent and stable dispersion. The dispersion liquid is added with 5% by mass of silicone-acrylic emulsion, and the mixture is uniformly stirred at room temperature to obtain a self-cleaning functional coating agent. The above-mentioned film coating agent is sprayed on the surface of the building exterior wall paint for secondary coating, and is naturally dried at normal temperature to form a multifunctional coating with anti-fouling, anti-ultraviolet radiation and air purificatio...

Embodiment 3

[0034]Firstly, a nano-titanium oxide composite sol with a solid content of 2% was prepared, in which the titanium oxide was in anatase crystal form and the particle diameter was less than 10 nm, and a mixture of 3% sodium dodecyl sulfonate and diethanolamine was added to the sol, wherein The ratio of fatty alcohol polyoxyethylene ether sodium sulfate and diethanolamine is 2:1, and after vigorous stirring, it is dispersed in an aqueous sodium hydroxide solution with pH=10 to form a transparent and stable dispersion. The dispersion liquid is added to the pure acrylic emulsion with a mass percentage of 2%, and the mixture is stirred evenly at room temperature to obtain a self-cleaning functional coating agent. The above-mentioned film coating agent is sprayed on the surface of the building exterior wall paint for secondary coating, and is naturally dried at normal temperature to form a multifunctional coating with anti-fouling, anti-ultraviolet radiation and air purification prope...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com