Molten-salt solid solution and method and device for preparing same

A preparation device and solid solution technology, which is applied in chemical instruments and methods, lighting and heating equipment, inorganic chemistry, etc., can solve the problems of poor corrosion resistance of preparation devices, easily affected composition and physical and chemical properties, and achieve the effect of reducing corrosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

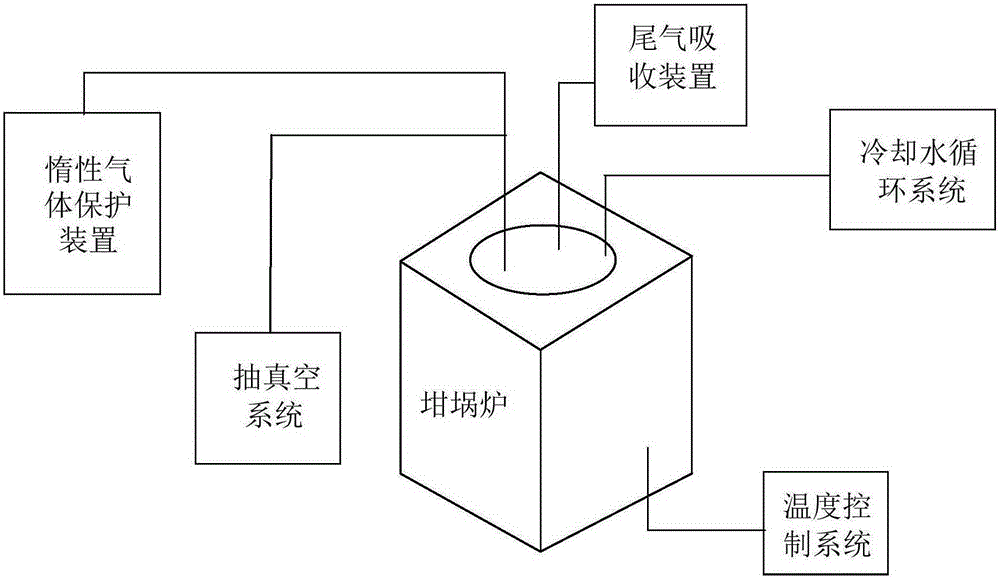

[0042] A preparation device for molten salt solid solution, its schematic diagram is as follows figure 1 As shown, the preparation device consists of a crucible furnace and an auxiliary system connected to the crucible furnace, wherein the auxiliary system includes a temperature control system, an inert atmosphere protection device, a vacuum system, a cooling water circulation system and an exhaust gas absorption device.

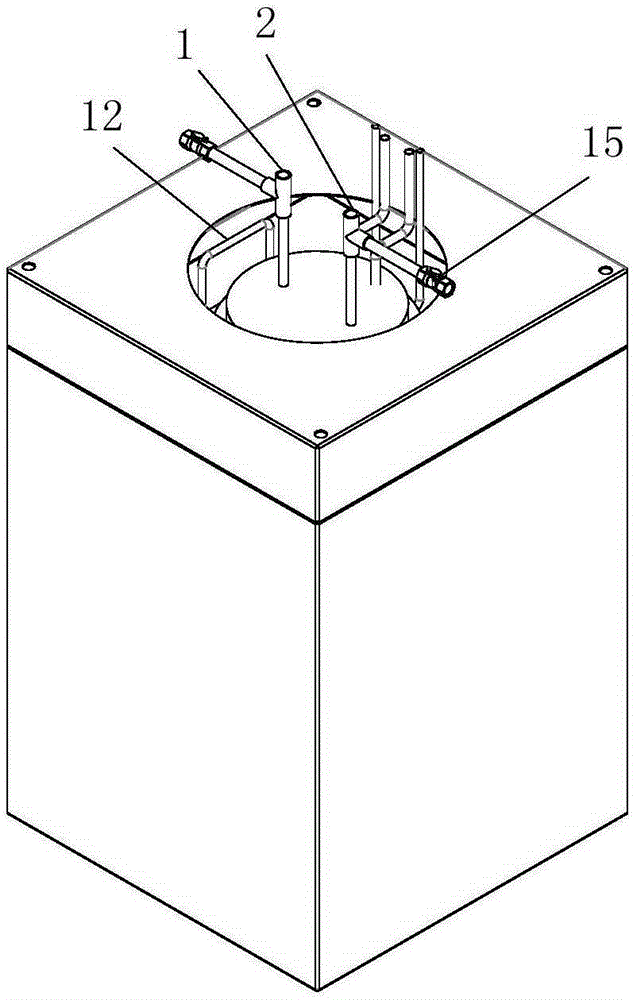

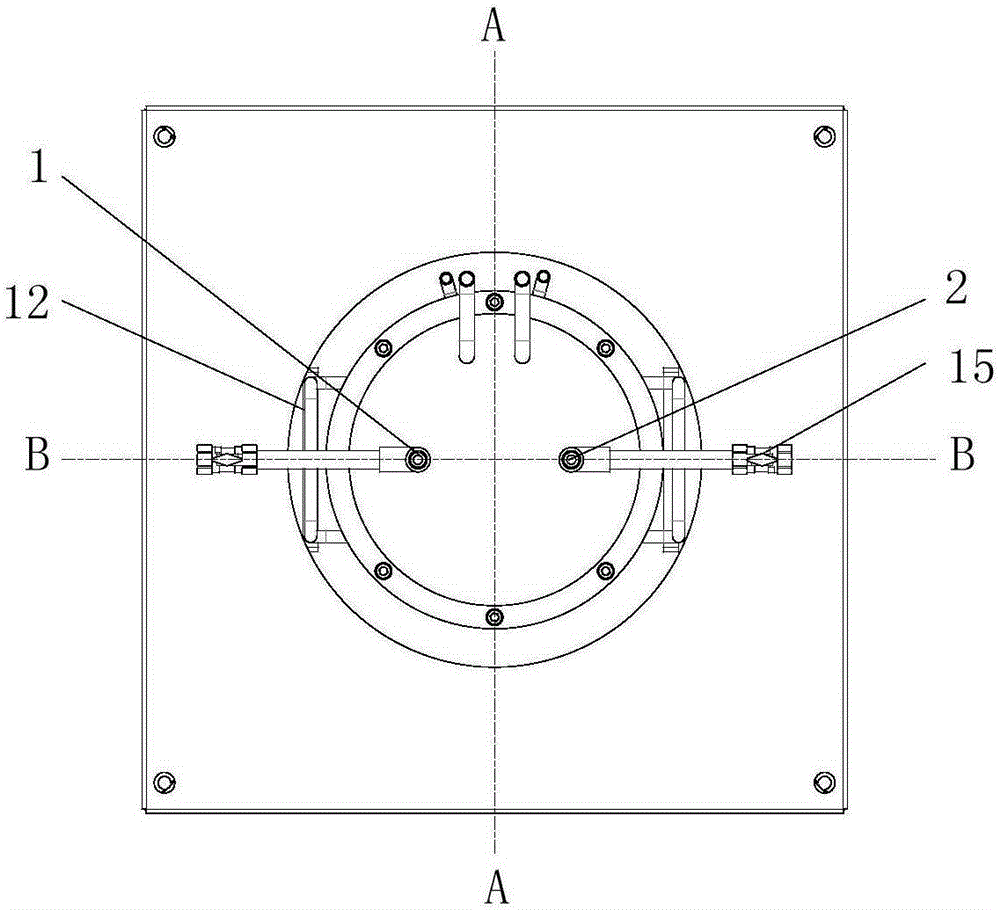

[0043] Among them, the structure of the crucible furnace is as follows Figure 2-5 as shown, figure 2 Schematic diagram of the structure of the crucible furnace, image 3 is the top view of the crucible furnace, Figure 4 is the cross-sectional view of the crucible furnace along line A-A, Figure 5 It is a sectional view of the crucible furnace along the line B-B. Such as Figure 2-5 As shown, the crucible furnace includes an inner furnace shell bracket 4, an outer furnace shell 5, an inner furnace shell 6, an inner tank 9, a furnace 7, an insulation l...

Embodiment 2

[0049] This embodiment describes the specific preparation method for preparing molten salt solid solution using the preparation device of Embodiment 1:

[0050] Program the temperature of the crucible furnace through the temperature control system, and preheat the furnace 7 to 150°C; then mix LiNaKF, ThF 4 and UF 4 Solid molten salt, a total of 10g, was put into a glassy carbon crucible, and this operation was carried out in a glove box; after that, two corundum bricks were placed at the bottom of the inner tank 9 of the crucible furnace, and the glassy carbon crucible was quickly transferred from the glove box to the inner tank. In the tank 9, close the inner tank cover 10;

[0051] Open the vacuum system and continue to heat the crucible furnace. When the temperature in the inner tank 9 rises to 350°C, keep the constant temperature and open the cooling water circulation system; meanwhile, open the inert atmosphere protection device and use argon to replace the air in the cr...

Embodiment 3

[0054] This embodiment describes the specific preparation method for preparing molten salt solid solution using the preparation device of Embodiment 1:

[0055] Program the temperature of the crucible furnace through the temperature control system, and preheat the furnace chamber 7 to 150°C; then mix uniformly LiNaKF and UF 4 Solid molten salt, a total of 20.5g, was put into a glassy carbon crucible, and this operation was carried out in a glove box; after that, two corundum bricks were placed at the bottom of the inner container 9 of the crucible furnace, and then the glassy carbon crucible was quickly transferred from the glove box In the inner container 9, close the inner container cover 10;

[0056] Open the vacuum system and continue to heat the crucible furnace. When the temperature in the inner tank 9 rises to 350°C, keep the constant temperature and open the cooling water circulation system; meanwhile, open the inert atmosphere protection device and use argon to replac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com