GaN dual heterogeneity node field effect transistor structure and its making method

A field effect transistor, gallium nitride based technology, applied in the fields of semiconductor/solid state device manufacturing, semiconductor devices, electrical components, etc. Adverse effects of electron gas transport properties, difficulties in epitaxial growth, etc., to reduce electron scattering, suppress current collapse effect, and improve mobility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

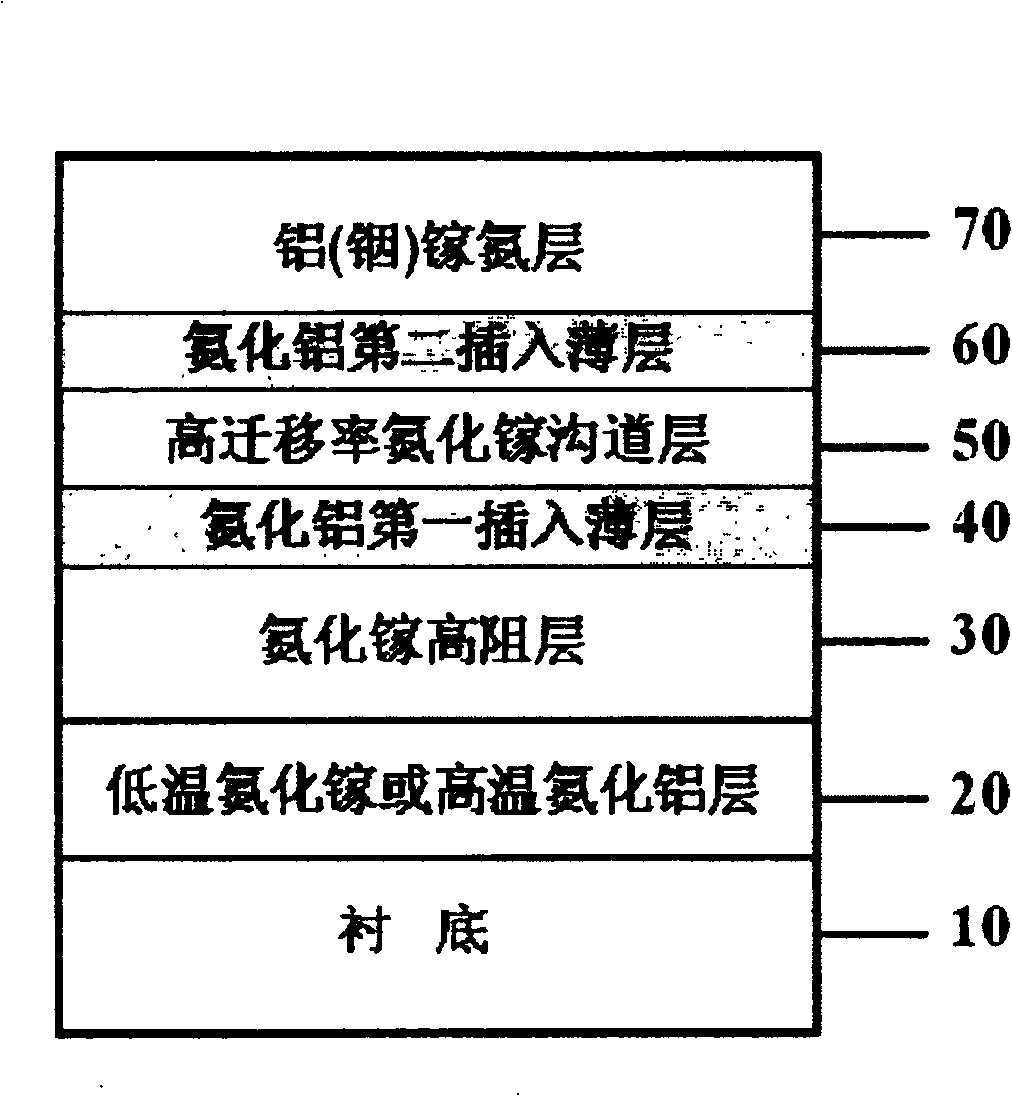

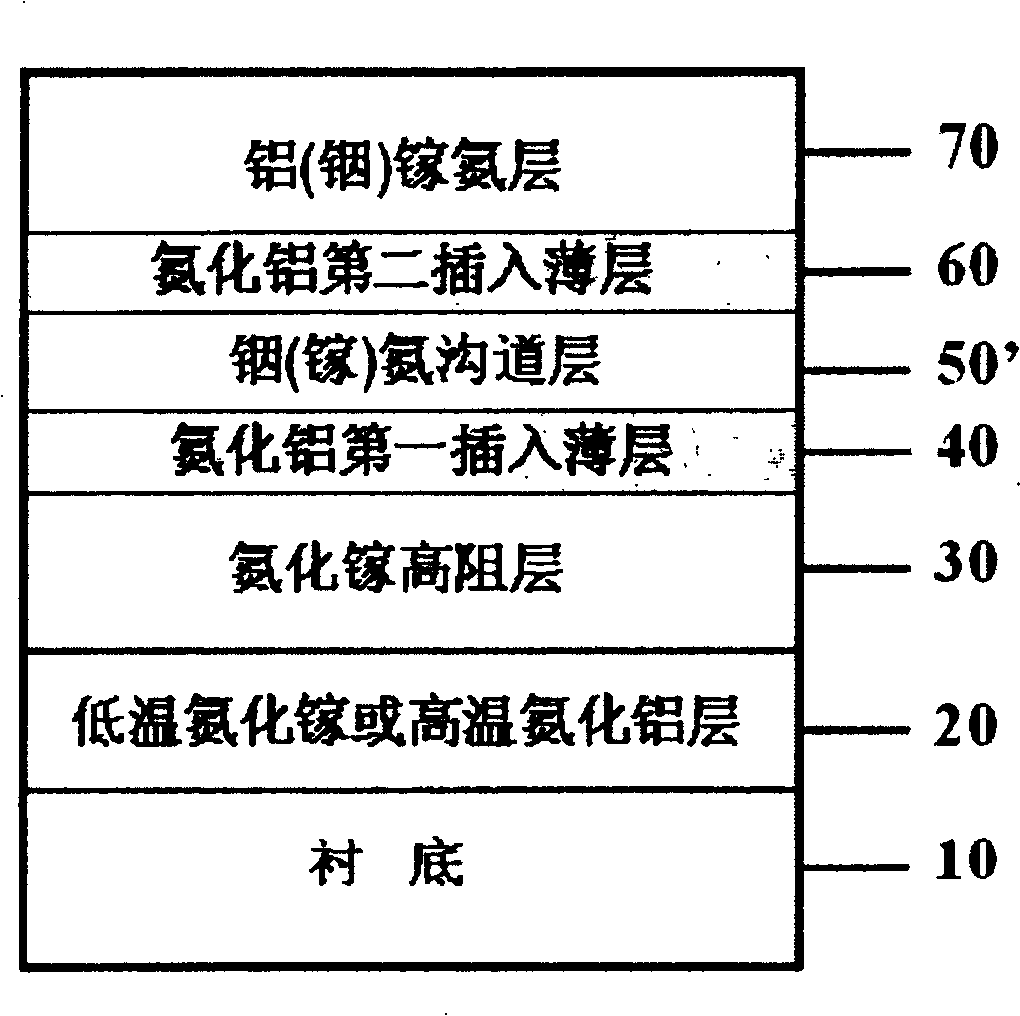

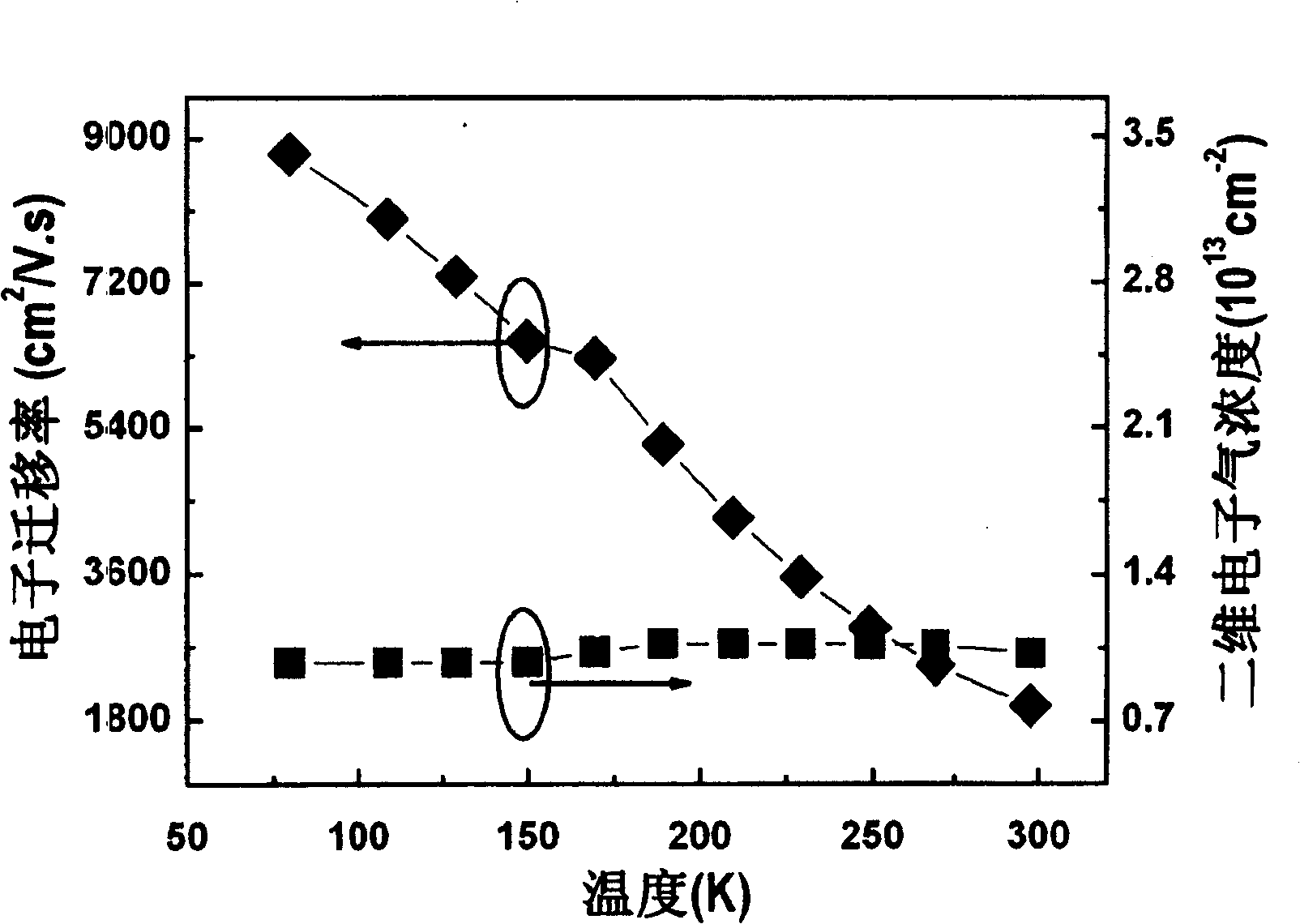

[0059] The present invention is a gallium nitride-based double heterojunction field effect transistor structure using a double aluminum nitride insertion layer. Between the channel layer and the aluminum (indium) gallium nitride barrier layer, and between the gallium nitride-based channel layer and the gallium nitride high-resistance buffer layer, insert thin layers of aluminum nitride to form a double heterogeneous field effect Transistor structure, through precise control of growth conditions, such as temperature, pressure, V / III ratio, high-quality gallium nitride-based double heterojunction field effect transistor structure materials are grown. Double aluminum nitride inserted into the thin layer can further increase the barrier height on both sides of the channel layer, which can better confine the two-dimensional electron gas in the channel layer, and effectively limit the flow of electrons to the aluminum (indium) gallium nitrogen barrier. layer and GaN buffer layer lea...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com