Preparation method for ferrite, ferrite and inductor

A technology of ferrite and nickel oxide, applied in the direction of transformer/inductor core, etc., can solve the problem of ferrite's weak resistance to current impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

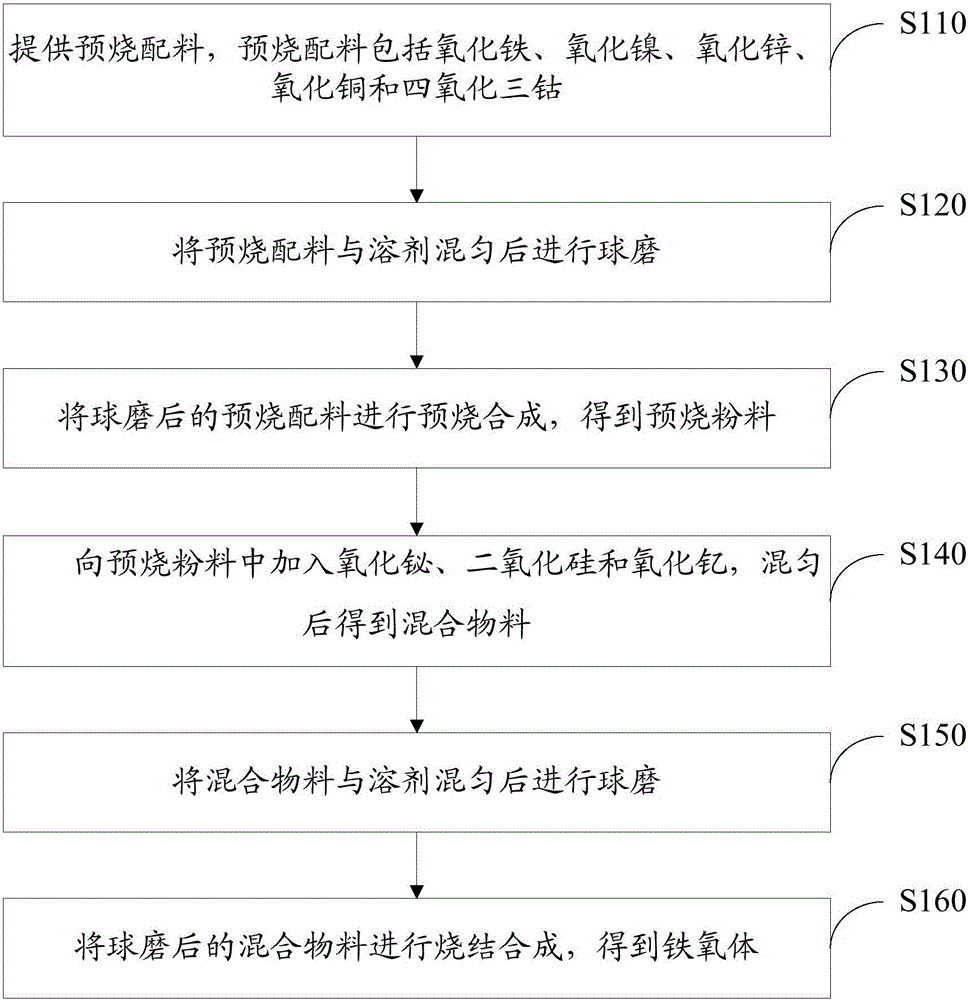

[0024] The preparation method of ferrite will be further described in detail mainly in conjunction with the accompanying drawings.

[0025] Such as figure 1 As shown, the method for preparing ferrite according to one embodiment includes the following steps S110-S160.

[0026] S110, providing pre-fired ingredients, the pre-fired ingredients include iron oxide, nickel oxide, zinc oxide, copper oxide and tricobalt tetroxide.

[0027] By iron oxide (Fe 2 o 3 ) by adding nickel oxide (Ni 2 o 3 ), zinc oxide (ZnO) and copper oxide (CuO) can be used to prepare NiCuZn soft magnetic ferrite, which has a high initial permeability and can be used for high-current inductors. Further add tricobalt tetroxide (Co 3 o 4 ), the resistance of the ferrite can be increased by cobalt tetroxide, thereby enhancing the ability of the ferrite to resist current impact.

[0028] Iron oxide, nickel oxide, zinc oxide, copper oxide and cobalt tetroxide are all commercially available. In this embod...

Embodiment 1

[0072] (1) Weigh the materials according to the following ratio (unit: g, tolerance: ±10%)

[0073] Material

Fe 2 o 3

Ni 2 o 3

ZnO

CuO

co 3 o 4

Deionized water

Zirconium ball

weight

62.77

8.44

19.67

9.02

0.10

100

400

[0074] The diameter of zirconium balls is 7mm, the mass ratio of pre-fired ingredients: balls: water is 1:4:1, the speed is 350 rpm, and ball milling is carried out for 4 hours. After discharging, drying, and passing through a 60-mesh sieve, put it in a mullite crucible, and prepare for pre-firing synthesis.

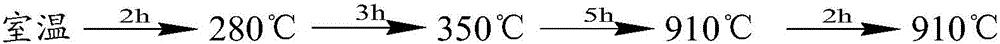

[0075] (2) Pre-fired synthesis

[0076] Pre-burning equipment: box furnace

[0077] Heating curve: starting from room temperature, the temperature is raised to 830°C at a rate of 2.5°C / min;

[0078] Heat preservation: keep heat at 830°C for 2.5 hours, close the box furnace, and cool the pre-fired powder to room temperature with the furnace.

[0079] (3) Weigh ...

Embodiment 2

[0090] (1) Weigh the materials according to the following ratio (unit: g, tolerance: ±10%)

[0091] Material

Fe 2 o 3

Ni 2 o 3

ZnO

CuO

co 3 o 4

Deionized water

Zirconium ball

weight

64.18

7.35

19.63

8.75

0.09

100

400

[0092] The diameter of zirconium balls is 7mm, the mass ratio of pre-fired ingredients: balls: water is 1:4:1, the speed is 350 rpm, and ball milling is carried out for 4 hours. After discharging, drying, and passing through a 60-mesh sieve, put it in a mullite crucible, and prepare for pre-firing synthesis.

[0093] (2) Pre-fired synthesis

[0094] Pre-burning equipment: box furnace

[0095] Heating curve: starting from room temperature, the temperature is raised to 855°C at a rate of 2.5°C / min;

[0096] Heat preservation: keep heat at 855°C for 2.5 hours, close the box furnace, and cool the pre-fired powder to room temperature with the furnace.

[0097] (3) Weigh ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Average particle size | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com