Limitation-enhanced GaN-based deep ultraviolet laser

A deep ultraviolet and laser technology, applied in the direction of lasers, semiconductor lasers, phonon exciters, etc., can solve the problems of increased activation energy, increased difficulty of P-type doping, and affecting the transmission of hole active regions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments, but the protection scope of the present invention is not limited thereto.

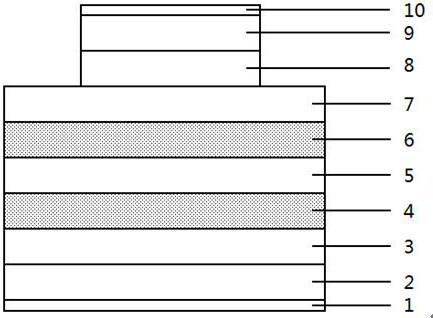

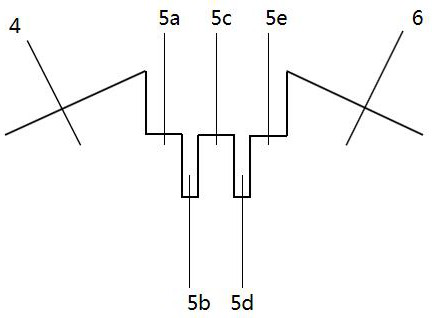

[0024] Such as figure 1 A confinement-enhanced GaN-based deep ultraviolet laser is shown, from bottom to top are N-type electrode 1, substrate 2, N-type lower confinement layer 3, N-type Al x Ga 1-x N lower waveguide layer 4, active region 5, P-type Al x Ga 1-x N upper waveguide layer 6 , P type electron blocking layer 7 , P type upper confinement layer 8 , P type ohmic contact layer 9 and P type electrode 10 . More specifically:

[0025] The N-type electrode 1 is made of Ti / Al / Ti / Au material with a thickness of 70 / 150 / 70 / 200nm.

[0026] Substrate 2 is an AlN substrate with a thickness of 100 μm.

[0027] N-type lower confinement layer 3 is grown on AlN substrate 2, and the material is Al 0.55 Ga 0.45 N, with a thickness of 2 μm.

[0028] N-type Al is grown on th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com