Method for preparing high niobium containing titanium aluminium alloy powder

A high-niobium titanium-aluminum, pre-alloyed powder technology, applied in the field of powder metallurgy, can solve the problems of tissue sensitivity, easy pollution, and inability to maintain purity, and achieve the effect of good sphericity and high purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

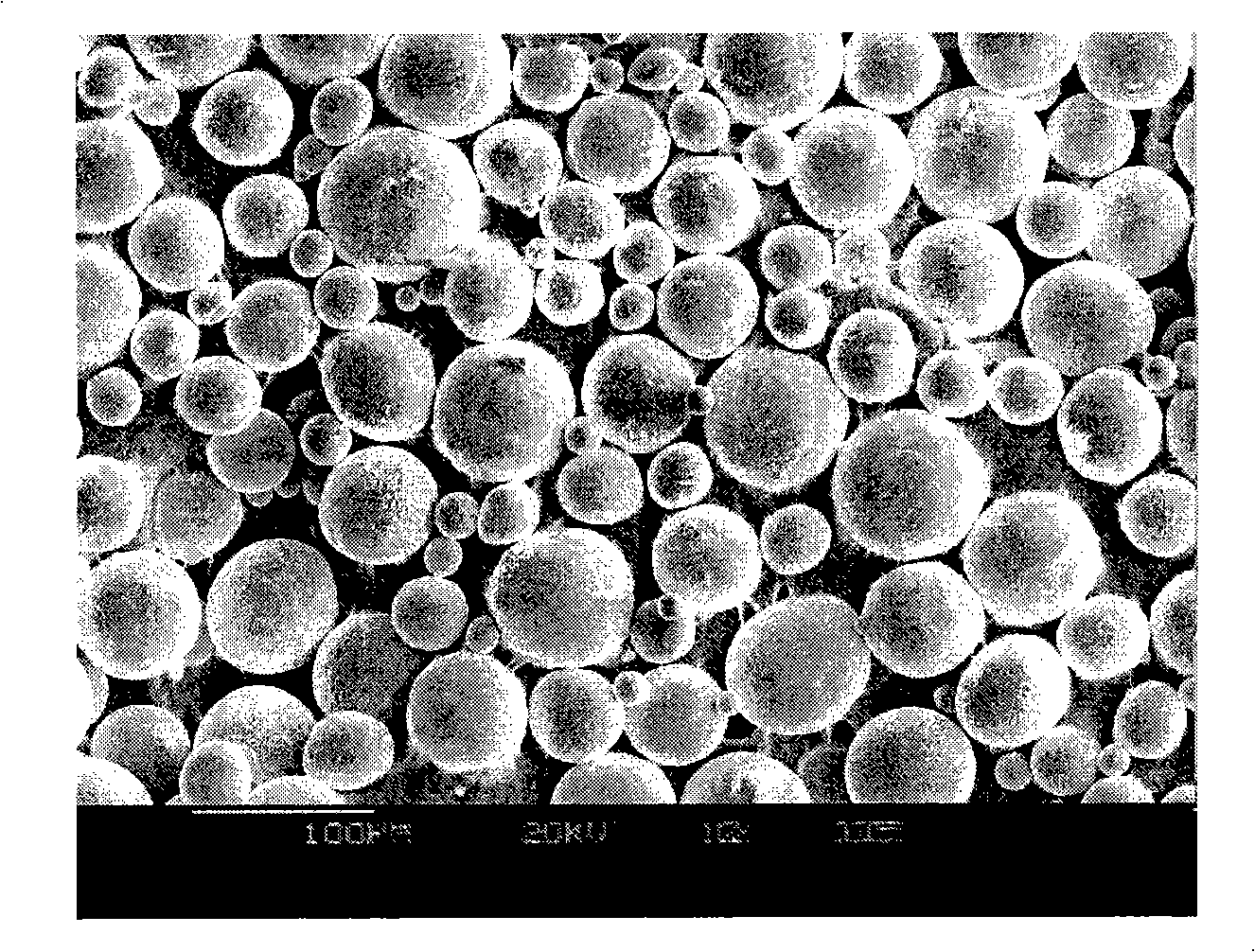

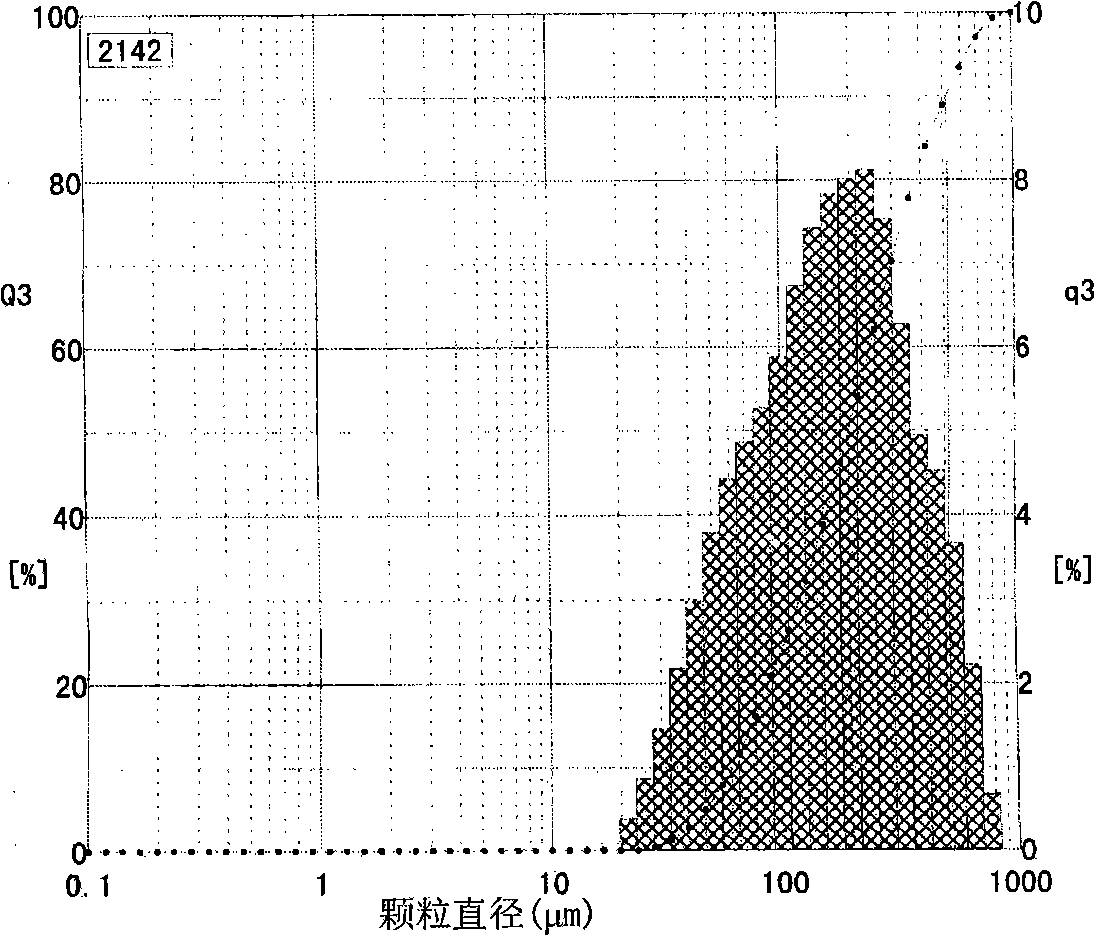

[0024] Use plasma cooling bed process to melt high-niobium titanium-aluminum ingot, keep it at 1200°C for 24 hours, and carry out soaking treatment; then remove the surface oxide scale of the ingot; use the wire cutting method to process the ingot into a diameter that can be connected It is a bar with a length of 20mm and a length of 220mm, and then it is turned to remove the iron oxide scale on the surface of the bar; the bar is made into powder by a continuous inert gas atomization process without crucible induction heating, and the process parameters are inert gas pressure 3.0MPa, argon Flow 180Ls -1 . The sphericity of the prepared powder reaches 92%, and the powder yield is 85%. When the particle size is -200 mesh, the oxygen content in the alloy powder is 1150ppm.

Embodiment 2

[0026] The high-niobium titanium-aluminum alloy is smelted by the consumable solidification process to make a round bar billet with a diameter of 30mm and a length of 150mm, and then the surface oxide skin of the billet is removed, and the billet is processed into a diameter of 25mm and a length that can be connected. The bar is 140mm; the bar is made into powder by induction heating continuous inert gas atomization process without crucible, the process parameters are inert gas pressure 3.0MPa, argon flow rate 200L s -1 . The sphericity of the prepared powder reaches 93%, and the powder yield is 87%. When the particle size is -200 mesh, the oxygen content in the alloy powder is 1200ppm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com