Electro-chemistry detecting method for fast identifying peripheral nerve bundle nature

A peripheral nerve and detection method technology, applied in biochemical equipment and methods, microbial determination/inspection, measuring devices, etc., can solve the problems of in-situ staining, clinical application limitations, long staining time, etc., and achieve simplified steps, fast identification, low-cost results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1a

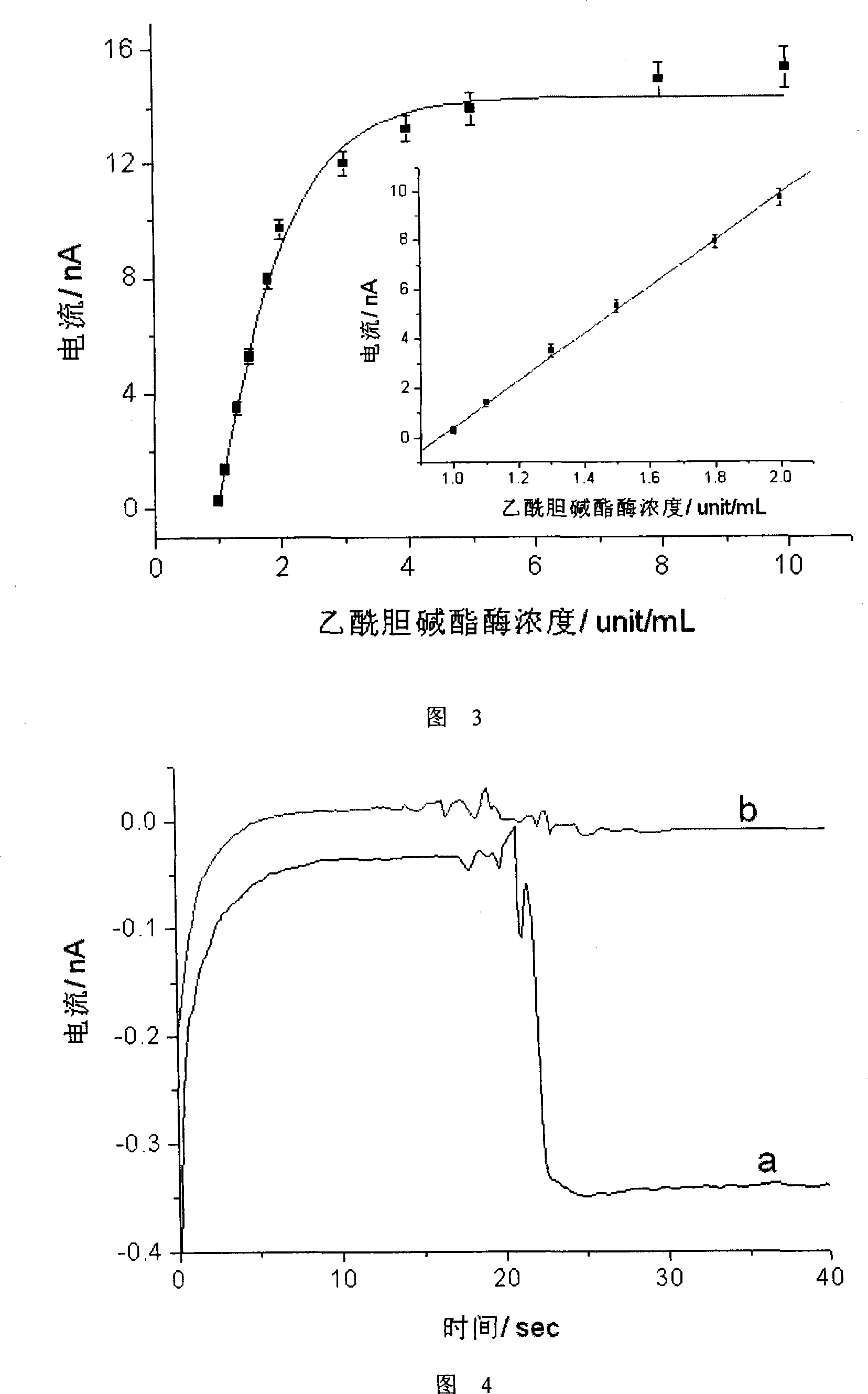

[0031] Before the experiment, the gold plate electrode (4) was polished on silicon carbide fine sandpaper, and then polished into a "mirror surface" with suede with 0.3 μm and 0.05 μm alumina suspension, and finally cleaned by ethanol and secondary water ultrasonically. ,spare.

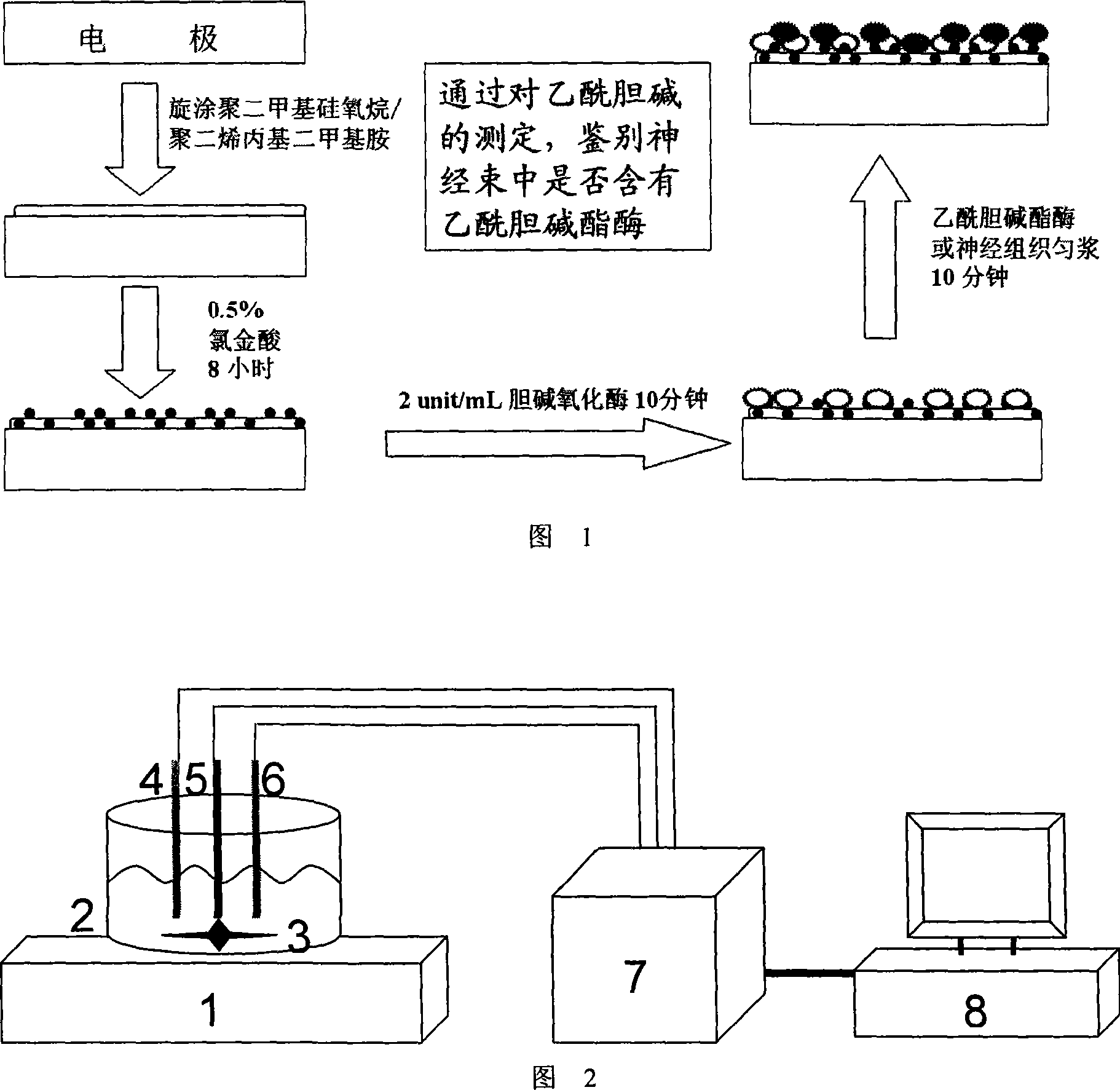

[0032]1. In the process of modifying the electrode, first fix the gold electrode in the spin coater with the surface facing up, and mix 0.1mL of 20% polydimethyldiallylamine aqueous solution with a mass ratio of 7:10:1 (weight-average molecular weight 100000, Aldrich company), polydimethylsiloxane (weight-average molecular weight 60000) and curing agent (Sylgard 184 Dow Coming company) are drip-coated on the electrode surface, start the spin coater, at 2000 rpm Rotate at a high speed for 15 minutes, and then stand in an oven at 80°C for one hour to solidify the polymer film on the electrode surface.

[0033] 2. Immerse the gold electrode modified polymer film into a beaker containing 0.5% chloroauric...

Embodiment 1b

[0039] Before the experiment, the gold plate electrode (4) was polished on silicon carbide fine sandpaper, and then polished into a "mirror surface" with suede with 0.3 μm and 0.05 μm alumina suspension, and finally cleaned by ethanol and secondary water ultrasonically. ,spare.

[0040] 1. In the process of modifying the electrode, first fix the gold electrode in the spin coater with the surface facing up, and mix 0.1 mL of 20% polydimethyldiallylamine ( Weight-average molecular weight 20000, Aldrich company) aqueous solution, polydimethylsiloxane (weight-average molecular weight 60000) and curing agent (Sylgard 184 Dow Corning company) are drip-coated on the electrode surface, start the spin coater, at 2500 rpm Rotate at a high speed for 15 minutes, and then stand in an oven at 80°C for one hour to solidify the polymer film on the electrode surface.

[0041] Other steps are the same as Example 1a, and the result obtained is exactly the same as Example 1a.

Embodiment 2

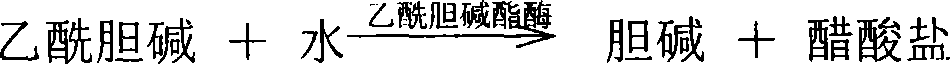

[0043] 1. The Beagle dogs were anesthetized and killed in stages, and the spinal canal was opened from the middle of the back immediately, and the T section running from the epidural to the entrance of the spinal nerve root canal was taken. 12 -S 2 For the anterior root and posterior root of the spinal nerve (the anterior root is the motor nerve, and the posterior root is the sensory nerve), fresh specimens of the two types of nerve roots of each dog were put into specimen bottles, and quickly stored in liquid nitrogen for future use. Naturally thaw at room temperature when taking it, and store it in a wet box after thawing to prevent the specimen from drying and dehydrating.

[0044] 2. Immerse a nerve specimen in 0.05M 1mL pH7.4 phosphate buffer solution and break it up in a tissue homogenizer. Then centrifuge at 10,000 rpm at 4°C for 15 min, take the supernatant and add ammonium sulfate to 25% saturation. Afterwards, centrifuge at 10000 rpm at 4°C for 15 min, remove the p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com