Diamond compound film piece used for absolute bolometer and method for producing the same

A bolometer and composite diaphragm technology is applied in the field of radiation-absorbing diamond composite diaphragm and its preparation, which can solve the problems of low sensitivity, low measurement accuracy of radiometer, low thermal conductivity, etc., so as to improve adaptability and service life, improving measurement accuracy and sensitivity, and the effect of small changes in absorption rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

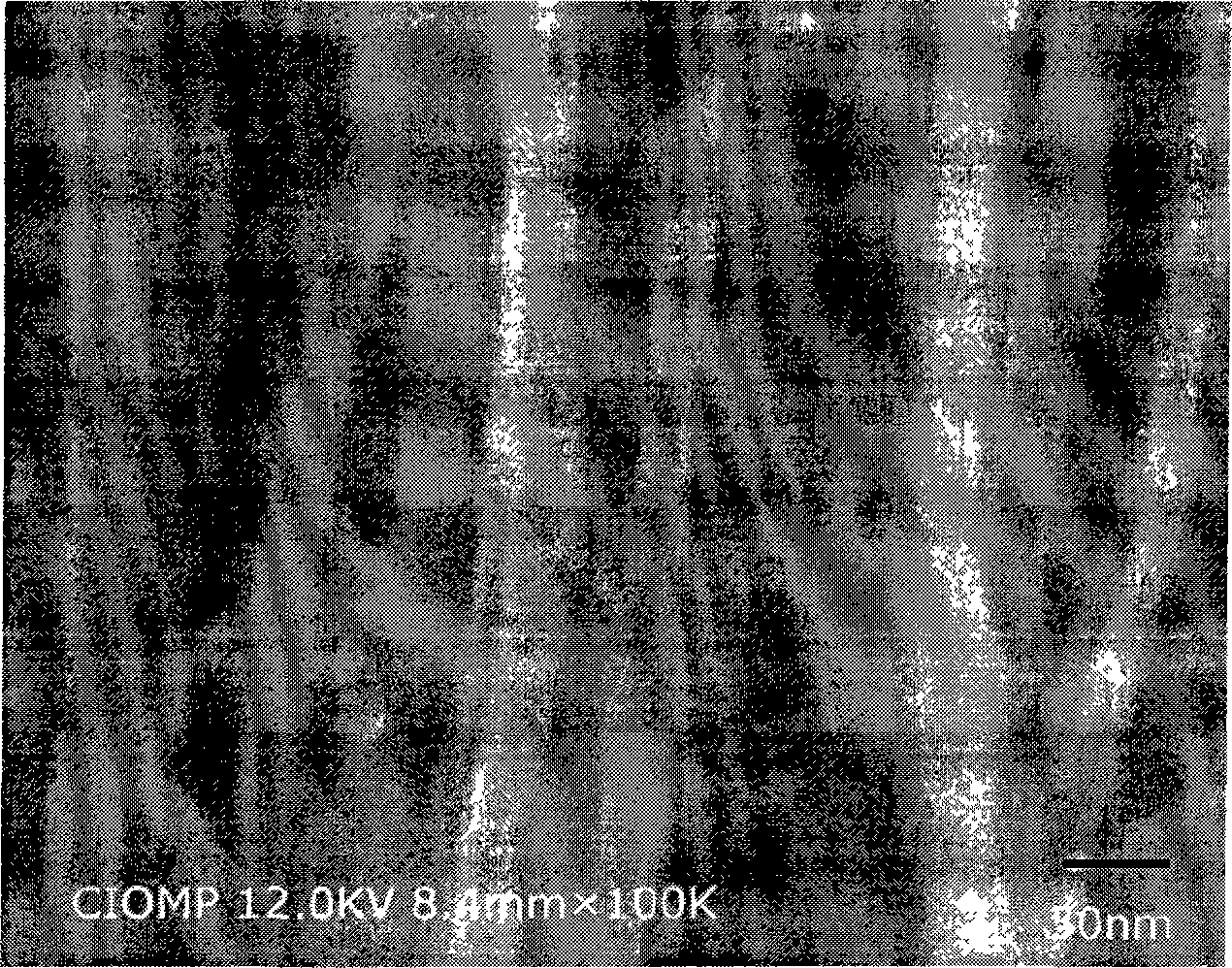

Embodiment 1

[0021] A diamond composite diaphragm used on an absolute bolometer is composed of a pure diamond sheet as a heat sink material and a carbon nanotube film as a light radiation absorbing material, and the diamond sheet is a thermal Conductivity ≥ 15W / K cm, resistivity 10 13 ~10 15 Ω·cm colorless transparent diaphragm; the carbon nanotube film layer is a tubular structure formed by carbon atoms bonded and interconnected, evenly distributed on the diamond sheet, and the carbon nanotube film layer has a thermal conductivity of 7 ~10W / K·cm, resistivity 10 9 ~10 13 Ω·cm.

[0022] Concrete preparation process is as follows:

[0023] (1) A chemical vapor deposition heat sink diamond sheet. The heat sink diamond film is prepared by MW-PCVD microwave plasma chemical vapor deposition system, which belongs to the electrodeless discharge method, and high-quality high-purity transparent diamond film can be obtained under relatively low pressure. Metal molybdenum plate was used as the s...

Embodiment 2

[0031] Prepare the diamond composite diaphragm used on the absolute absolute bolometer by the same method steps as in Example 1, the difference is only in:

[0032] (1) The process condition of a chemical vapor deposition heat sink diamond sheet is: H 2 The flow rate is 200sccm, CH 4 The flow rate is 1sccm, the microwave power is 3.8KW, the deposition pressure is 17KPa, the substrate temperature is 950°C, and the growth rate is about 1μm / h. The obtained diamond diaphragm has a thermal conductivity of 18W / K cm and a resistivity of 10 15 Ω·cm.

[0033] (2) The technological conditions of the deposition of carbon nanotube film layer by the floating catalytic method are: in the heating stage, the reaction chamber is filled with N 2 Protection, control its flow rate to 55sccm; when the reaction temperature reaches 800°C, feed C 2 h 2 gas while controlling C 2 h 2 The gas flow rate is 35sccm, N 2 The flow control is 200sccm, and the quality of ferrocene is controlled at 0.6g...

Embodiment 3

[0036] Prepare the diamond composite diaphragm used on the absolute absolute bolometer by the same method steps as in Example 1, the difference is only in:

[0037] (1) The process condition of a chemical vapor deposition heat sink diamond sheet is: H 2 The flow rate is 200sccm, CH 4 The flow rate is 2sccm, the microwave power is 4KW, the deposition pressure is 13KPa, the substrate temperature is 750°C, and the growth rate is about 2μm / h. The thermal conductivity of the prepared diamond sheet is 17W / K cm, and its resistivity is 10 14 Ω·cm.

[0038] (2) The technological conditions of the deposition of carbon nanotube film layer by the floating catalytic method are: in the heating stage, the reaction chamber is filled with N 2 Protection, control its flow rate to 50sccm; when the reaction temperature reaches 800°C, feed C 2 h 2 gas while controlling C 2 h 2 The gas flow rate is 40sccm, N 2 The flow control is 170sccm, and the ferrocene quality is controlled at 0.75g. A...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistivity | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com