Antistatic coating and preparation method thereof, and application of antistatic coating

An anti-static and coating technology, applied in conductive coatings, coatings and other directions, can solve the problems of poor mechanical properties of ordinary anti-static PVC materials, poor graphene dispersion, environmental pollution, etc., to improve mechanical properties and thin coating thickness. , the effect of reducing the dosage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

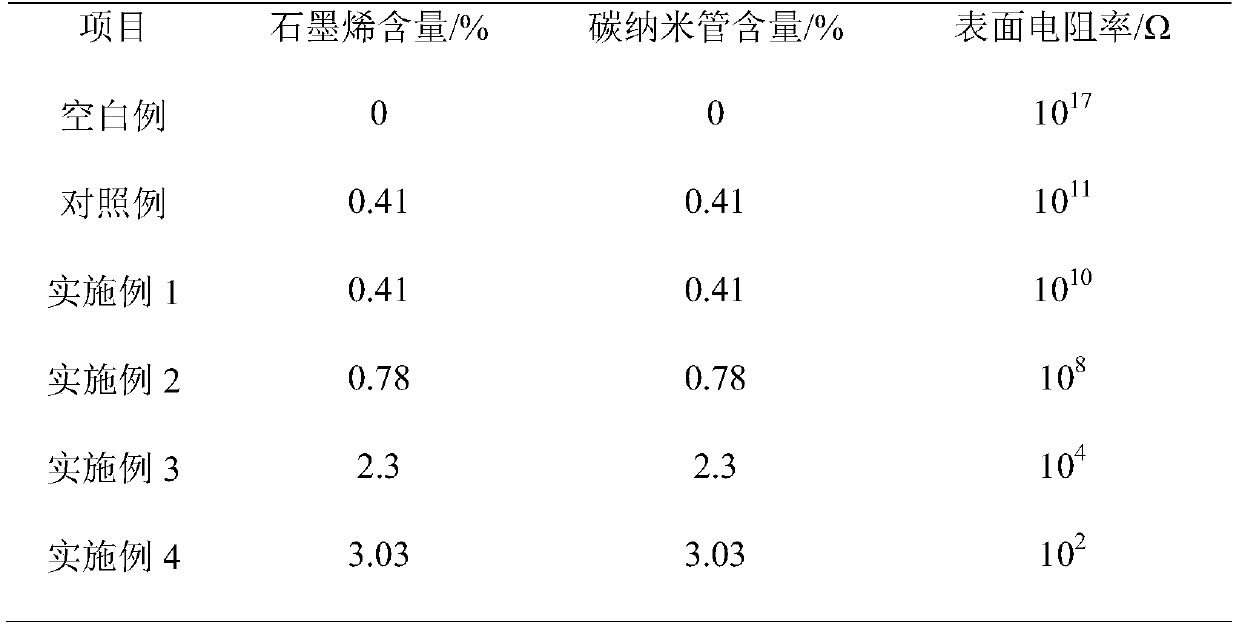

Examples

Embodiment 1

[0037] (1) Take the following graphene slurry components by weight: 1 part by weight graphene, 1 part by weight carbon nanotube, 100 parts by weight DOP, 0.5 part by weight polyvinylpyrrolidone;

[0038] (2) adding the material taken in step (1) into a sand mill, and grinding for 2 hours to obtain a graphene slurry;

[0039] (3) Take the following graphene PVC paste resin antistatic coating components by weight: 100 parts by weight PVC paste resin, 80 parts by weight of graphene slurry of step (2) gained, 2 parts by weight stabilizer, 2 parts by weight Calcium carbonate, 1 part by weight of stearic acid;

[0040] (4) adding the material taken by step (3) into a high-speed disperser and mixing for 1 hour, obtaining graphene PVC paste resin antistatic coating;

[0041] (5) Weighing the graphene PVC paste resin antistatic coating obtained in step (4) and coating it on a PVC plate, baking at 150° C. for 3 minutes and performing a performance test.

Embodiment 2

[0043] (1) Take the following graphene slurry components by weight: 2 parts by weight of graphene, 2 parts by weight of carbon nanotubes, 100 parts by weight of DOP, 1 part by weight of polyvinylpyrrolidone;

[0044] (2) adding the material taken in step (1) into a sand mill, and grinding for 2 hours to obtain a graphene slurry;

[0045](3) take by weight the following graphene PVC paste resin antistatic coating components: 100 parts by weight of PVC paste resin, 20 parts by weight of vinyl chloride paste resin, 100 parts by weight of the graphene slurry of step (2) gained, 3 Parts by weight stabilizer, 5 parts by weight calcium carbonate, 2 parts by weight stearic acid;

[0046] (4) adding the material taken by step (3) into a high-speed disperser and mixing for 1 hour, obtaining graphene PVC paste resin antistatic coating;

[0047] (5) Weighing the graphene PVC paste resin antistatic coating obtained in step (4) and coating it on a PVC plate, baking at 150° C. for 3 minutes...

Embodiment 3

[0049] (1) Take the following graphene slurry components by weight: 5 parts by weight of graphene, 5 parts by weight of carbon nanotubes, 100 parts by weight of DOP, 3 parts by weight of polyvinylpyrrolidone;

[0050] (2) adding the material taken in step (1) into a sand mill, and grinding for 2 hours to obtain a graphene slurry;

[0051] (3) take by weight the following graphene PVC paste resin antistatic coating components: 100 parts by weight of PVC paste resin, 30 parts by weight of vinyl chloride paste resin, the graphene slurry of 200 parts by weight of step (2) gained, 5 parts by weight Parts by weight stabilizer, 8 parts by weight calcium carbonate, 3 parts by weight stearic acid;

[0052] (4) adding the material taken by step (3) into a high-speed disperser and mixing for 1 hour, obtaining graphene PVC paste resin antistatic coating;

[0053] (5) Weighing the graphene PVC paste resin antistatic coating obtained in step (4) and coating it on a PVC plate, baking at 150...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| degree of polymerization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com