A kind of low shrinkage, high rebound epe beads and preparation method thereof

A high-rebound, low-shrinkage technology, applied in the field of low-shrinkage, high-rebound EPE beads and their preparation, can solve the problems of inability to meet dimensional accuracy requirements, high shrinkage of EPE beads, large surface gloss and other problems , to achieve excellent mechanical properties, good surface gloss, and good dimensional stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

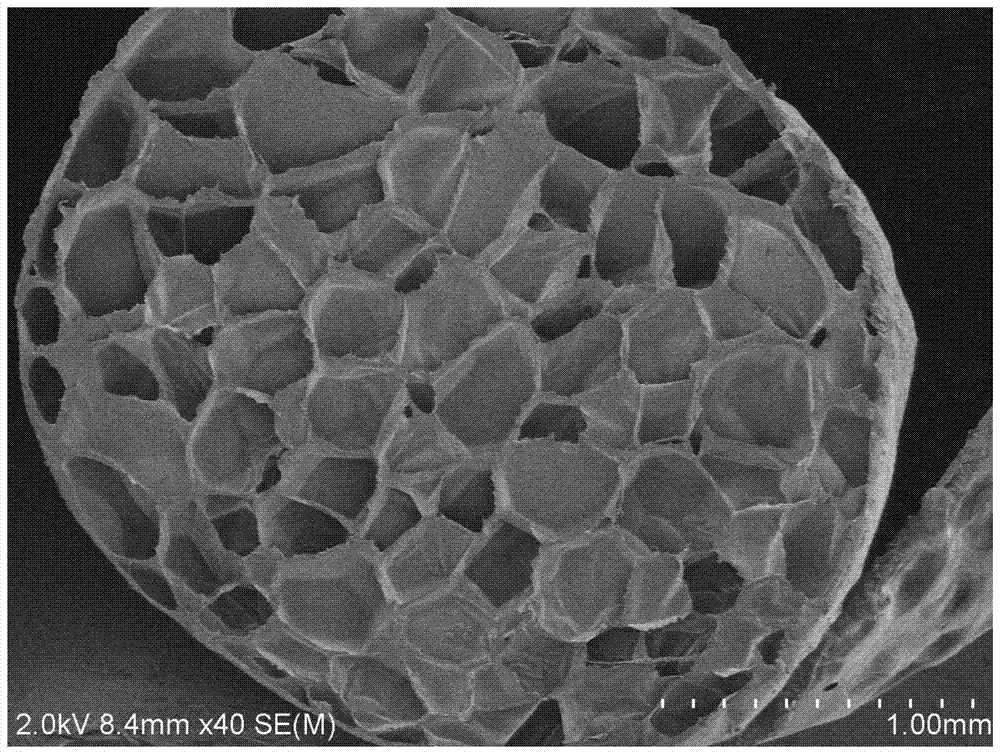

Image

Examples

Embodiment 1

[0036] A low shrinkage, high resilience EPE beads with a density of 15g / L. The formulation of the EPE beads includes the following components by weight:

[0037] 70 parts of non-metallocene catalyzed LLDPE resin, 20 parts of HDPE resin, 2 parts of antistatic agent and 8 parts of auxiliary agent;

[0038] Wherein, the MFR of the non-metallocene-catalyzed LLDPE resin is 1g / 10min, and the MFR of the HDPE resin is 2g / 10min;

[0039] The auxiliary agent is glycerin and polyethylene glycol.

[0040] The preparation method of the low shrinkage EPE beads adopts the following steps:

[0041] 1) First, mix and stir the non-metallocene-catalyzed LLDPE resin, HDPE resin, antistatic agent, and auxiliary agents according to the ratio;

[0042] 2). The above-mentioned mixed materials are subjected to extruder drawing and pelletizing to obtain polyethylene resin particles suitable for foaming; the diameter of the obtained polyethylene resin particles is 0.5mm;

[0043] 3) Disperse polyethylene resin par...

Embodiment 2

[0046] A kind of low shrinkage and high resilience EPE beads with a density of 100g / L, including the following components by weight:

[0047] 93.5 parts of non-metallocene catalyzed LLDPE resin, 5 parts of HDPE resin, 0.5 part of antistatic agent and 1 part of auxiliary agent;

[0048] Wherein, the MFR of the non-metallocene catalyzed LLDPE resin is 3g / 10min, and the MFR of the HDPE resin is 5g / 10min;

[0049] The auxiliary agent is polypropylene glycol neutralized palmitamide.

[0050] The preparation method of the low shrinkage EPE beads adopts the following steps:

[0051] 1) First, mix and stir the non-metallocene-catalyzed LLDPE resin, HDPE resin, antistatic agent, and auxiliary agents according to the ratio;

[0052] 2) The above-mentioned mixed material is subjected to extruder drawing and pelletizing to obtain polyethylene resin particles suitable for foaming; the diameter of the obtained polyethylene resin particles is 6mm;

[0053] 3) Disperse polyethylene resin particles in an ...

Embodiment 3

[0056] A kind of low shrinkage, high resilience EPE beads with a density of 80g / L. The formulation of the EPE beads includes the following components by weight:

[0057] 67 parts of non-metallocene catalyzed LLDPE resin, 20 parts of HDPE resin, 3 parts of antistatic agent and 10 parts of fatty acid glyceride;

[0058] Wherein the MFR of the non-metallocene catalyzed LLDPE resin is 2g / 10min, and the MFR of the HDPE resin is 3.5g / 10min;

[0059] The preparation method of the low shrinkage EPE beads adopts the following steps:

[0060] 1) First, mix and stir the non-metallocene-catalyzed LLDPE resin, HDPE resin, antistatic agent, and auxiliary agents according to the ratio;

[0061] 2) The above-mentioned mixed materials are subjected to extruder drawing and pelletizing to obtain polyethylene resin particles suitable for foaming; the diameter of the obtained polyethylene resin particles is 3mm;

[0062] 3) Disperse polyethylene resin particles in an aqueous dispersion medium, put them into...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com