Method for processing sweet potato beverage

A processing method and technology of sweet potato, applied in the field of non-alcoholic beverage preparation, can solve the problems of sweet potato active protein, active polysaccharide denaturation and inactivation, unutilized potato residue, anthocyanin loss and fading, etc. Nutritional value, prevention of constipation and intestinal diseases, effect of reducing vitamin loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0050] A kind of processing method of sweet potato beverage mainly is made up of following steps:

[0051] A, cleaning: the fresh sweet potato (the weight percentage composition of water in the fresh sweet potato is generally 50-90%) is cleaned manually or mechanically (can be automatically) with water, removes mud sand and impurity, and fresh sweet potato can be peeled or not peeled;

[0052] b. Crushing and grinding juice: Grinding the washed fresh sweet potatoes with a colloid mill or a refiner until the particles are less than 1000 microns to obtain sweet potato juice;

[0053] c. Sterilization: Pasteurize the raw sweet potato juice, or use ultra-high temperature instantaneous sterilization at 121°C for 3-15 seconds, or ultra-high temperature instantaneous sterilization at 130-150°C for 3-10 seconds, or use cobalt 60 (dose 1-10 1,000Gy) irradiation sterilization, or microwave sterilization for 1 to 20 minutes;

[0054] d. Canning: the sterilized sweet potato juice is asep...

Embodiment 2

[0057] A kind of processing method of sweet potato beverage is characterized in that comprising the following steps:

[0058] A, cleaning: the fresh sweet potato (the weight percentage composition of water in the fresh sweet potato is generally 50-90%) is cleaned manually or mechanically (can be automatically) with water, removes mud sand and impurity, and fresh sweet potato can be peeled or not peeled;

[0059] b. Crushing and grinding juice: Grinding the washed fresh sweet potatoes with a colloid mill or a refiner until the particles are less than 1000 microns to obtain sweet potato juice;

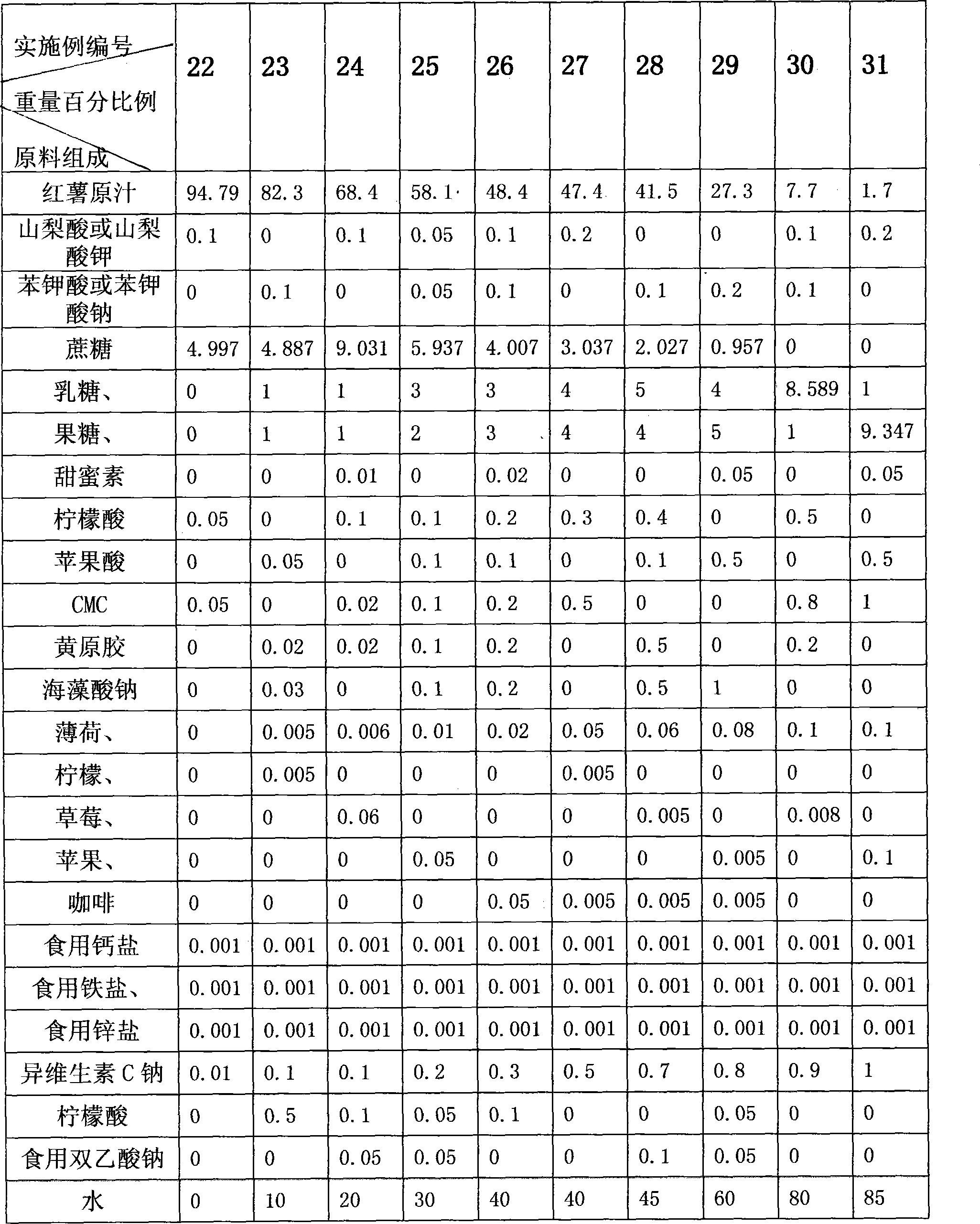

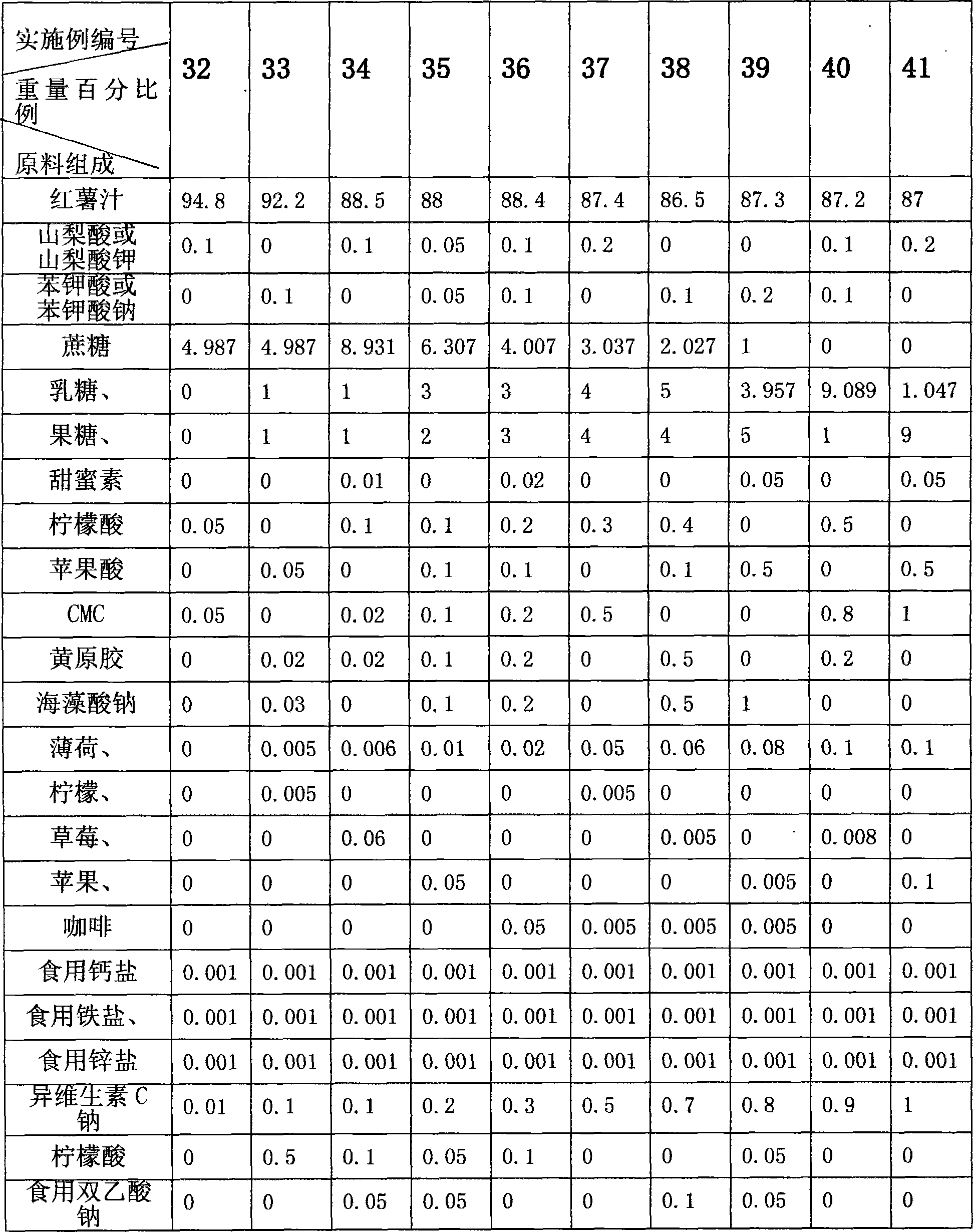

[0060] One or two or more of preservatives, sweeteners, sour agents, stabilizers, essences, vitamins or minerals are added to sweet potato juice (or after sterilization), and mixed evenly to obtain sweet potato juice;

[0061] The preservative can be sorbic acid, potassium sorbate, phenylpotassium acid or sodium benzoate in a weight percentage of 0.01 to 0.2%; the sweetener can be 0.1 t...

Embodiment 3

[0066] A kind of processing method of sweet potato beverage mainly is made up of following steps:

[0067] A, cleaning: the fresh sweet potato (the weight percentage composition of water in the fresh sweet potato is generally 50-90%) is cleaned manually or mechanically (can be automatically) with water, removes mud sand and impurity, and the fresh sweet potato can be peeled or not peeled;

[0068] b. Crushing and grinding juice: Grinding the washed fresh sweet potatoes with a colloid mill or a refiner until the particles are less than 1000 microns to obtain sweet potato juice;

[0069] In the process of crushing and grinding juice, 0.005-1% by weight of vitamin C, sodium isovitamin C or citric acid, or 0.05-0.1% of edible sodium diacetate, etc. are also added; the grinding and crushing of the step (b) The process can also be crushed under sealed conditions or vacuum degassing conditions to avoid discoloration of sweet potato juice and loss of nutrients;

[0070] c. Sterilizat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com