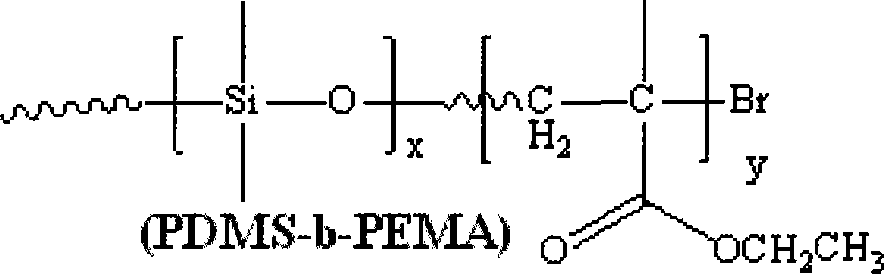

Method for synthesizing organic silicon di-block copolymers

A technology of block copolymers and synthesis methods, which is applied in the field of synthesis of silicone diblock copolymers, can solve the problems of reaction influence, high purity requirements, and the inability to contain oxygen and water, etc., and achieve mild reaction conditions and mild reactions Conditions, effect of narrow molecular weight distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

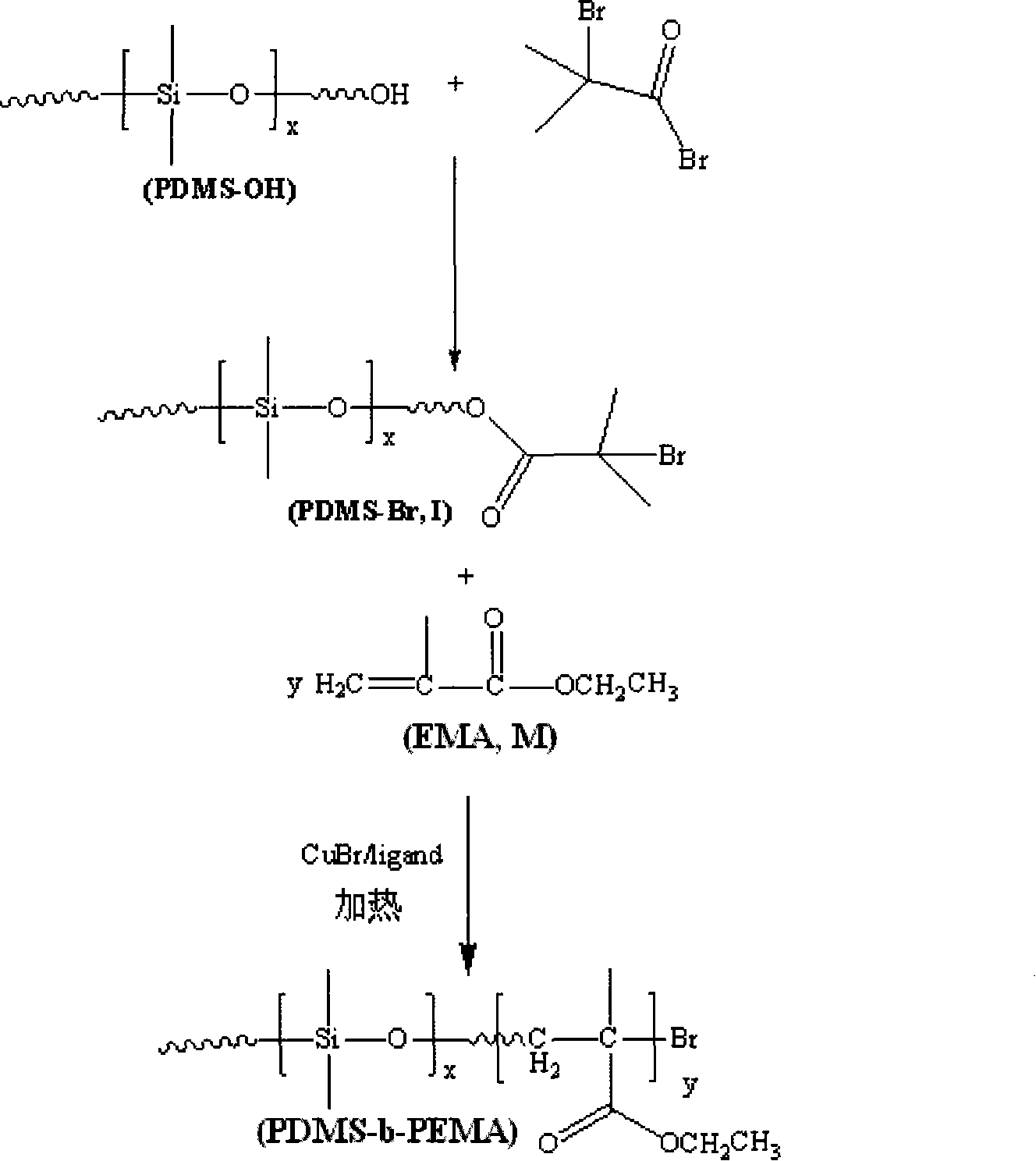

Method used

Image

Examples

Embodiment 1

[0020] 1) Under the protection of a nitrogen atmosphere, 1 part of monomethanol-terminated polydimethylsiloxane, 1.5 parts of 2-bromoisobutyryl bromide and 2.7 parts of triethylamine are reacted at 0°C. Then the above solution was stirred and reacted for 30h. After the reaction, it was filtered, the filtrate was distilled under reduced pressure to remove the solvent, and then dissolved in dichloromethane, washed with saturated sodium bicarbonate solution several times, separated, and the organic layer Dry with anhydrous magnesium sulfate to remove water, then filter, and finally distill the filtrate under reduced pressure to remove the methylene chloride solvent to obtain an oily yellow macroinitiator;

[0021] 2) The reaction system must be strictly deoxygenated, using 1 part of macromolecule as initiator, 1 part of cuprous bromide as catalyst, and 2 parts of N-(n-propyl)-2-pyridine methylamine as catalyst ligand React with 30 parts of ethyl methacrylate as a monomer at 40°C. Bef...

Embodiment 2

[0023] 1) Under the protection of an argon atmosphere, 1 part of monomethanol-terminated polydimethylsiloxane, 1.8 parts of 2-bromoisobutyryl bromide and 3 parts of triethylamine are reacted at 5°C. Then the above solution was stirred and reacted for 20 hours. After the reaction, it was filtered, the filtrate was distilled under reduced pressure to remove the solvent, and then dissolved in dichloromethane, washed twice with sodium bicarbonate solution, separated, and the organic layer Dry anhydrous magnesium sulfate to remove water, then filter, and finally distill the filtrate under reduced pressure to remove the dichloromethane solvent to obtain an oily yellow macroinitiator;

[0024] 2) The reaction system must strictly remove oxygen, using 1 part of macromolecule as initiator, 1 part of cuprous chloride as catalyst, and 2 parts of 1,1,4,7,7-pentamethyldivinyltriamine The catalyst ligand reacts with 40 parts of ethyl methacrylate as the monomer at 50°C. Before heating, the reac...

Embodiment 3

[0026] 1) Under the protection of a nitrogen atmosphere, 1 part of monomethanol-terminated polydimethylsiloxane, 2.5 parts of 2-bromoisobutyryl bromide and 4 parts of triethylamine are reacted at 15°C. Then, the above solution was stirred and reacted for 18 hours. After the reaction, it was filtered, the filtrate was distilled under reduced pressure to remove the solvent, and then dissolved in dichloromethane, washed twice with saturated sodium bicarbonate solution, separated, and the organic layer Dry with anhydrous magnesium sulfate to remove water, then filter, and finally distill the filtrate under reduced pressure to remove the methylene chloride solvent to obtain an oily yellow macroinitiator;

[0027] 2) The reaction system must strictly remove oxygen, using 1 part of macromolecule as initiator, 1 part of cuprous bromide as catalyst, and 2 parts of 1,1,4,7,7-pentamethyldivinyltriamine The catalyst ligand reacts with 55 parts of ethyl methacrylate as the monomer at 70°C. Bef...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com