Process for preparing high dispersion supported type transition metal phosphide catalyst

A transition metal and phosphide technology, which is applied in the field of preparation of highly dispersed supported transition metal phosphide catalysts, can solve problems such as uneven distribution of phosphides, and achieve easy large-scale preparation, improved dispersion degree, and high dispersion degree Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

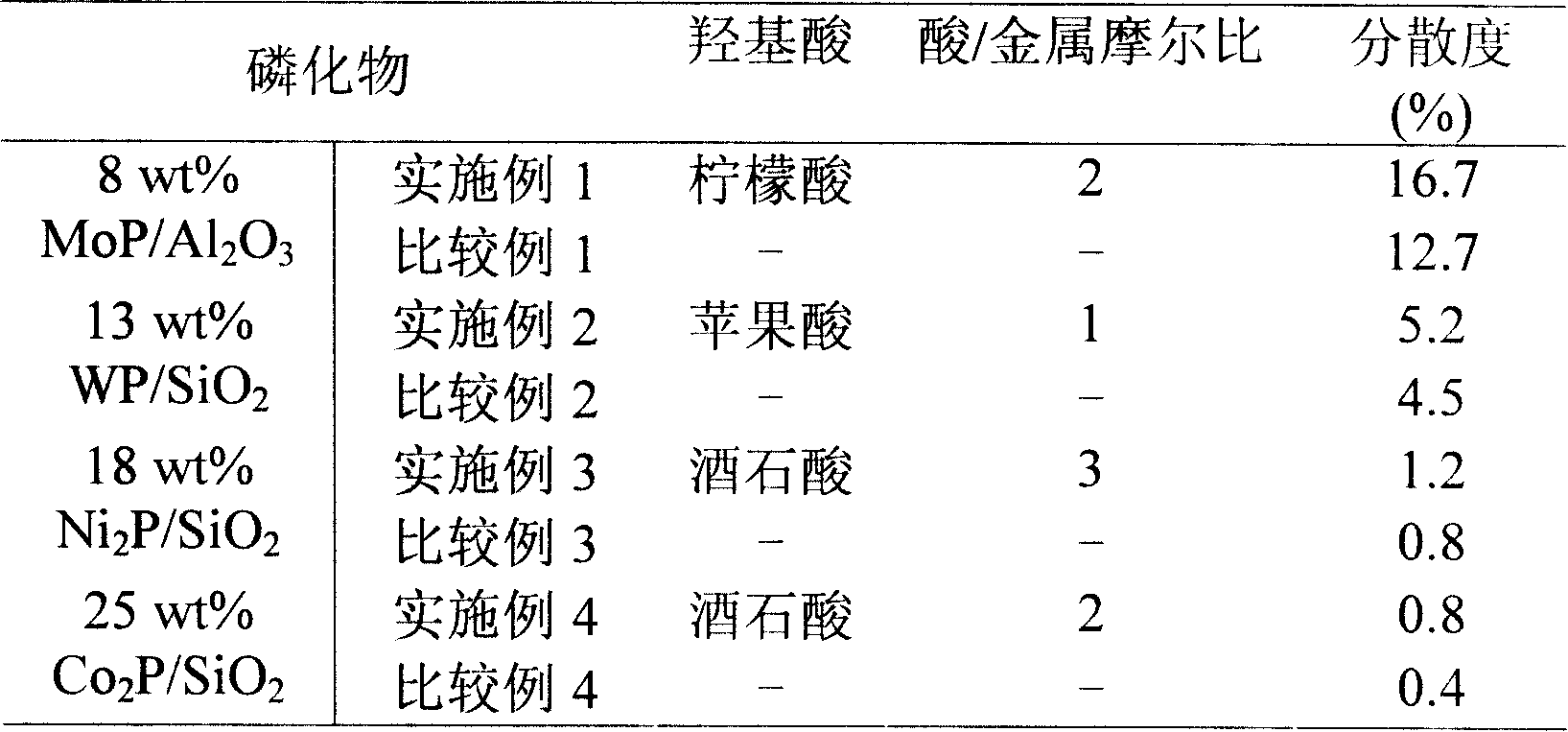

Embodiment 1

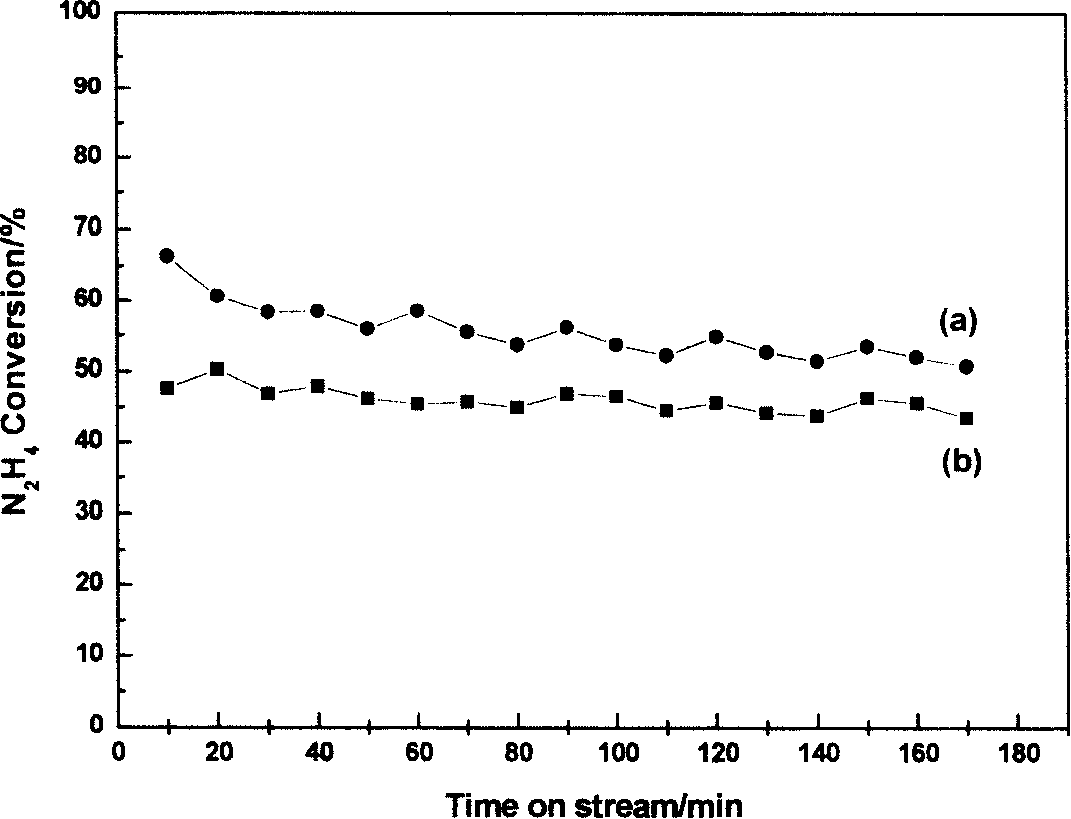

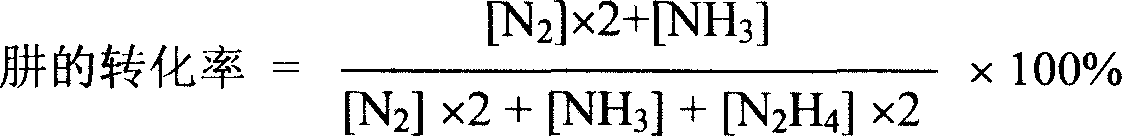

[0019] Example 1MoP / Al 2 o 3

[0020] The pore volume (mlg) of the carrier used was determined in advance -1 ), according to the amount of carrier, determine the water content in the impregnation solution. Al used in this example 2 o 3 The pore volume is 1.1mlg -1 . Weigh ammonium molybdate 0.364g and diammonium hydrogen phosphate 0.276g of target phosphide (MoP) stoichiometric ratio (molybdenum: phosphorus = 1: 1) and be dissolved in 3.3ml water, after completely dissolving, citric acid is added to above solution to obtain impregnation solution. The amount of citric acid and metal molybdenum is 2:1 (molar ratio). Weigh 3.0g Al 2 o 3 Immerse in the immersion solution, let stand for 6 hours, dry at 120°C for 12 hours, and finally calcinate at 500°C for 5 hours under a flowing air atmosphere to obtain a precursor. Under a hydrogen atmosphere, the precursor was raised from room temperature to 350 °C in 0.5 h, then raised to 850 °C at a rate of 5 °C / min, kept at this te...

Embodiment 2

[0023] Example 2 WP / SiO 2

[0024] The preparation method is the same as in Example 1. SiO used in this example 2 The pore volume is 1.5mlg -1 . Weigh 0.567g of ammonium metatungstate with the target phosphide (WP) stoichiometric ratio (tungsten: phosphorus = 1:1), and dissolve 0.275g of diammonium hydrogen phosphate in 4.5ml of water. After completely dissolving, add malic acid to the above solution to obtain an impregnating solution. The amount of malic acid and metal molybdenum is 1:1 (molar ratio). Weigh 3.0g SiO2 2 into the immersion solution. After standing still for 10 hours, it was dried at 140°C for 10 hours, and finally calcined at 450°C for 5 hours under a flowing air atmosphere to obtain a precursor. Under a hydrogen atmosphere, the precursor was raised from room temperature to 350 °C in 0.5 h, then raised to 750 °C at a rate of 5 °C / min, kept at this temperature for 2 h, and then cooled to room temperature. In order to prevent the violent oxidation reacti...

Embodiment 3

[0025] Example 3 Ni 2 P / SiO 2

[0026] Weigh the target phosphide (Ni 2 P) nickel nitrate 3.15g of stoichiometric ratio (nickel: phosphorus = 2: 1) is mixed with diammonium hydrogen phosphate 0.74g and dissolved in 4.5ml water, and a green precipitate is formed; 3:1) was added to the above solution, and after the tartaric acid was completely dissolved, a clear impregnation solution was obtained. Weigh 3.0g SiO2 2 Put it into the immersion solution, let it stand for 10 hours, dry it at 140°C for 10 hours, and finally calcinate it at 450°C for 5 hours under the flowing air atmosphere to obtain the precursor. Under a hydrogen atmosphere, the precursor was raised from room temperature to 350 °C in 0.5 h, then raised to 600 °C at a rate of 5 °C / min, and kept at this temperature for 2 h, then cooled to room temperature. In order to prevent the violent oxidation reaction of phosphide in contact with air, before the sample is exposed to air, use O 2 / N 2 (1% V / V) passivation fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com