Preparation method of hyperstable endovascular stent anticoagulant coatings

An anticoagulant and internal stent technology, applied in the field of biomedical materials, can solve problems such as poor stability, achieve the effects of increasing flexibility, reducing adhesion and aggregation, and improving anticoagulant performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

[0030] Specific implementation mode one: this implementation mode is realized in this way:

[0031] 1) Cleaning the intravascular stent material: Soak the Ni-Ti alloy in an organic solvent, sonicate for 1-120 min, and rinse with deionized water.

[0032] 2) use H 2 o 2 Boil the solution for 1-120 minutes, rinse with deionized water; etch with KOH solution for 1-120 minutes, rinse with deionized water.

[0033] 3) Electrostatic attraction self-assembled layer by layer diazo resin / heparin coating: put Ni-Ti alloy in 0.001-100mg / ml positively charged diphenylamine diazo resin solution, absorb for 0.5-30min, remove the solution and use Washing with deionized water; then putting the alloy into 0.001-100mg / ml negatively charged polyanion solution, absorbing for 0.5-30min, removing the solution and washing with deionized water. Repeat the above steps to assemble the diazo resin and polyanions alternately on the surface of the Ni-Ti alloy sheet until the required number of layers i...

specific Embodiment approach 2

[0043] Specific implementation mode two: this implementation mode is realized in this way:

[0044] 1) Electrostatic attraction layer-by-layer self-assembly of diphenylamine diazo resin and polyanion ultra-thin film including sodium alginate and heparin: put the Ni-Ti alloy sheet that has been oxidized and pretreated into 0.001~100mg / ml to be positively charged In the diphenylamine diazo resin solution, absorb for 0.5-30min, remove the solution and wash it with deionized water; then put the alloy sheet into 0.001-100mg / ml negatively charged polymer solution (sodium alginate or heparin), Adsorb for 0.5-30min, remove the solution and wash it with deionized water. Repeat the above steps to alternately assemble the diphenylamine diazo resin and polyanions on the surface of the Ni-Ti alloy sheet until the required number of layers is reached (the thickness is generally 1-1000 nm). After the reaction, the solution was taken out, washed with deionized water, and dried with nitrogen....

specific Embodiment approach 3

[0057] Specific implementation mode three: this implementation mode is realized in this way:

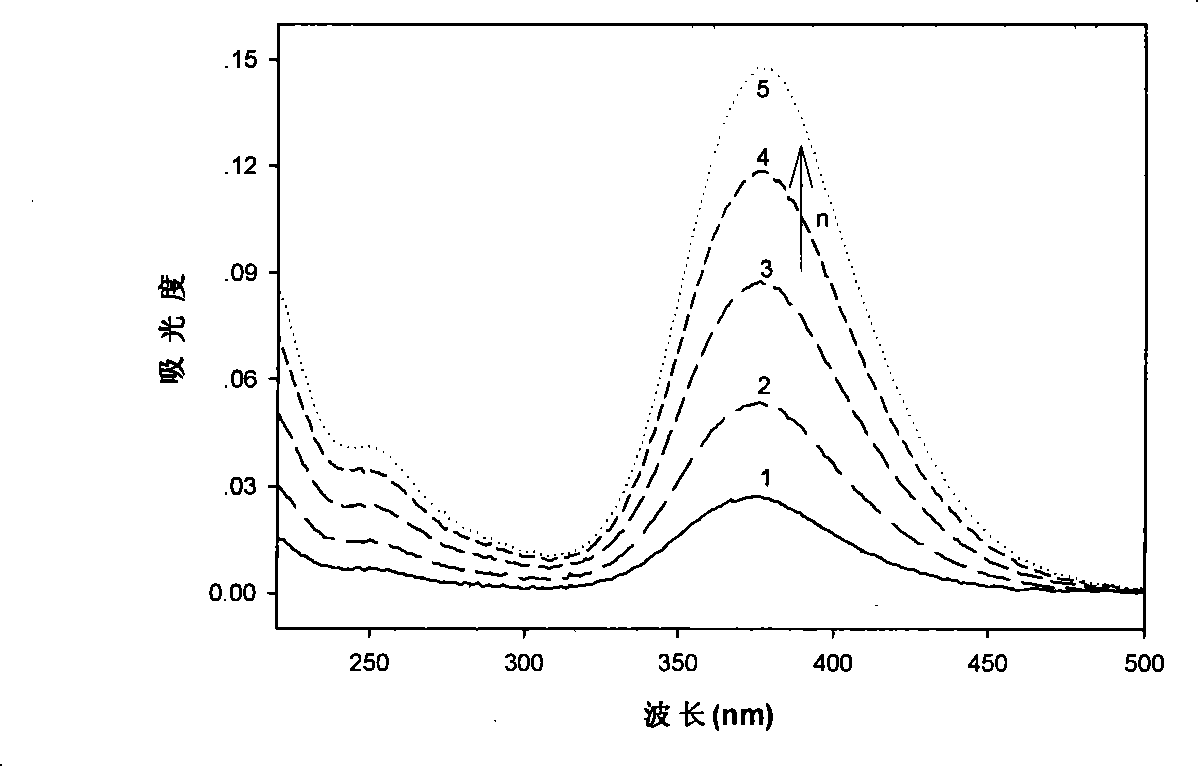

[0058] Electrostatic attraction layer by layer self-assembled multivalent metal cation solution and polyanion ultra-thin film including heparin: put the pretreated Ni-Ti alloy into 0.001-100mg / ml positively charged multivalent metal cation solution, Adsorb for 0.5-30min, remove the solution and shake and wash with deionized water; then put the alloy Ni-Ti into 0.001-100mg / ml negatively charged polyanion solution, the adsorption time is 0.5-30min, and wait for the adsorption of a layer of polyanion After anionization, the solution was removed and washed with deionized water, at which point the surface became negatively charged. Repeat the above steps to assemble metal ions and polyanions alternately on the surface of the Ni-Ti alloy sheet until the required number of layers is reached (the thickness is generally 1-10000nm). To prove that Fe 3+ And Hep can form a uniform multi-layer ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com