Bimaleimide resin modified by benzene dipropargyl ether and preparation method thereof

A technology of bismaleimide resin and m-phenylenedipropargyl ether, which is applied in the field of modified bismaleimide resin and its modification, and can solve the problem of heat resistance limitation of modified BMI resin

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

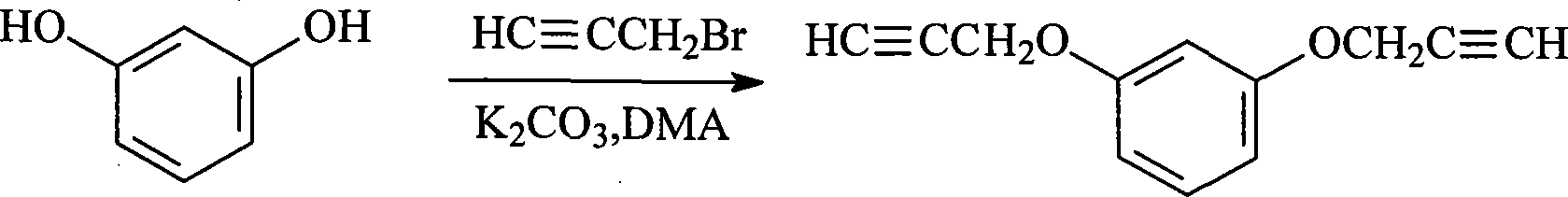

[0032] Synthesis of m-phenylenedipropargyl ether:

[0033] Add resorcinol 13.20g (0.12mol), potassium carbonate 39.74g (0.288mol), propyne bromide 34.27g ( 0.288mol) and 120ml DMA solvent. The reactant was stirred and heated to 60° C. under the protection of nitrogen, and reacted for 8 hours. After the reaction finishes, filter to remove solid salts, add a large amount of deionized water to the filtrate for cleaning, and then extract 3 times with toluene; combine the toluene layers, wash with 5% (wt) alkali first, then wash with water until neutral, evaporate toluene, The crude product was obtained as a pale yellow solid. Recrystallized twice from n-butanol to obtain a white crystalline product with a yield of 73%.

[0034] Product characterization:

[0035] Melting point: m.p.38~39℃.

[0036] NMR ( 1 H-NMR: CDCl 3 , TMS): δ: 2.6(tr, 2H, ≡CH), 4.7(d, 4H, -CH 2 ), 6.6 (m, 3H, -Ar-H), 7.2 (t, 1H, -Ar-H).

[0037] Infrared spectrum (FT-IR: KBr pellet): 3289cm -1 (≡C-H),...

Embodiment 2

[0040] Preparation of m-phenylenedipropargyl ether modified bismaleimide resin:

[0041] Take by weighing 18.0 g of m-phenylenedipropargyl ether synthesized in Example 1 and 36.0 g of diphenylmethane bismaleimide respectively, add in the reactor with agitator, thermometer and reflux condenser, and slowly heat up to 160°C, start stirring, and after the reactants are completely melted into a homogeneous phase, continue to stir and react for 1.5 hours to obtain a reddish-brown viscous pre-polymerized resin. Use Haake rheometer to analyze the dynamic viscosity of the pre-polymerized resin. The viscosity of the resin is lower than 1Pa.s between 120-170°C, and the retention time of the resin at 140°C is lower than 1Pa.s. The retention time is 100 minutes, which is beneficial to RTM Molding.

[0042] Pour the above pre-polymerized resin into the mold while it is hot, and place it in a vacuum oven at 100°C for 30 minutes for defoaming. Curing process: 180°C / 4h+220°C / 2h, post-treatme...

Embodiment 3

[0044] Preparation of m-phenylenedipropargyl ether modified bismaleimide resin:

[0045] The addition amount of raw material diphenylmethane bismaleimide and modifier m-phenylenedipropargyl ether is the same as in Example 2, then add 0.004g of catalyst copper chloride, follow-up operation is the same as in Example 2, and control the prepolymerization reaction time After 1 hour, a reddish-brown viscous prepolymerized resin was obtained. Use Haake rheometer to analyze the dynamic viscosity of the prepolymerized resin. The viscosity of the resin is lower than 1Pa.s between 120-166°C, and the retention time of the resin at 140°C is lower than 1Pa.s. The retention time is 70 minutes, which is beneficial to RTM Molding. .

[0046] The above prepolymerized resin is cured by the same curing process as in Example 2, and the cured product is subjected to dynamic mechanical analysis and thermogravimetric analysis respectively. As a result, it is found that the cured product does not ha...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com