Method for preparing compound coat between metals

A technology of intermetallic compounds and coatings, which is applied in the fields of electric power, machinery, material processing, aerospace, chemical industry, and metallurgy. Layer bonding strength, unfavorable service life and other problems, to achieve the effect of industrial application, low production cost and high output

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

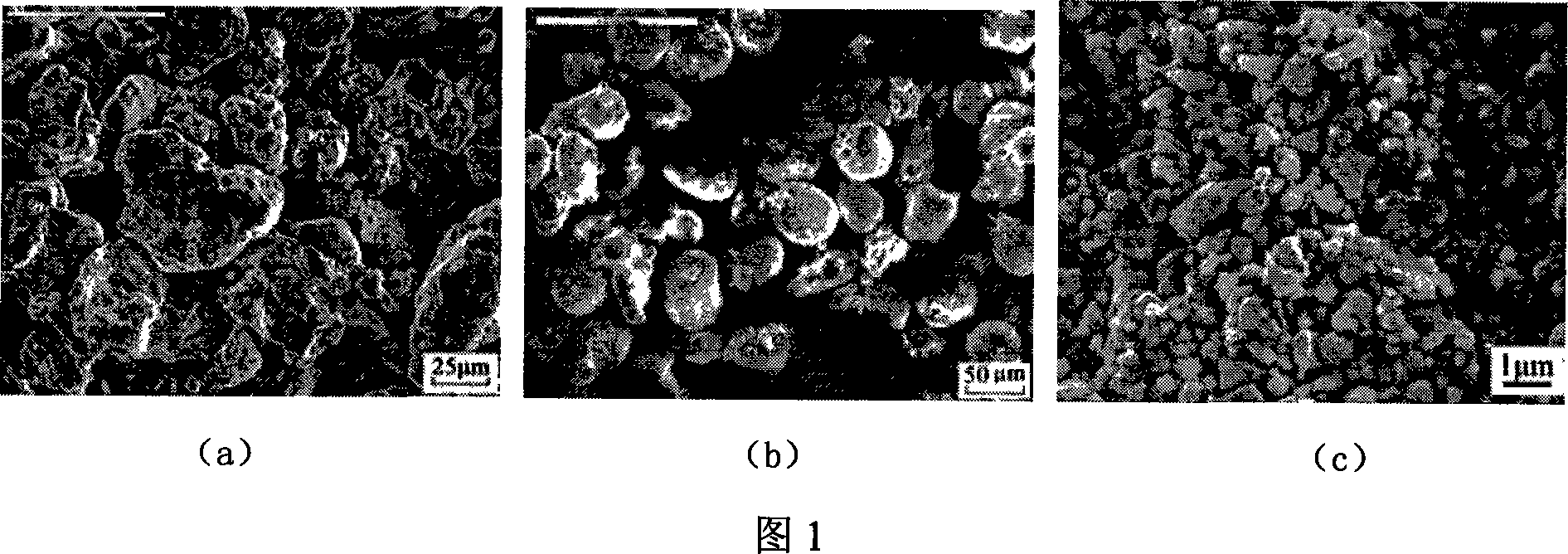

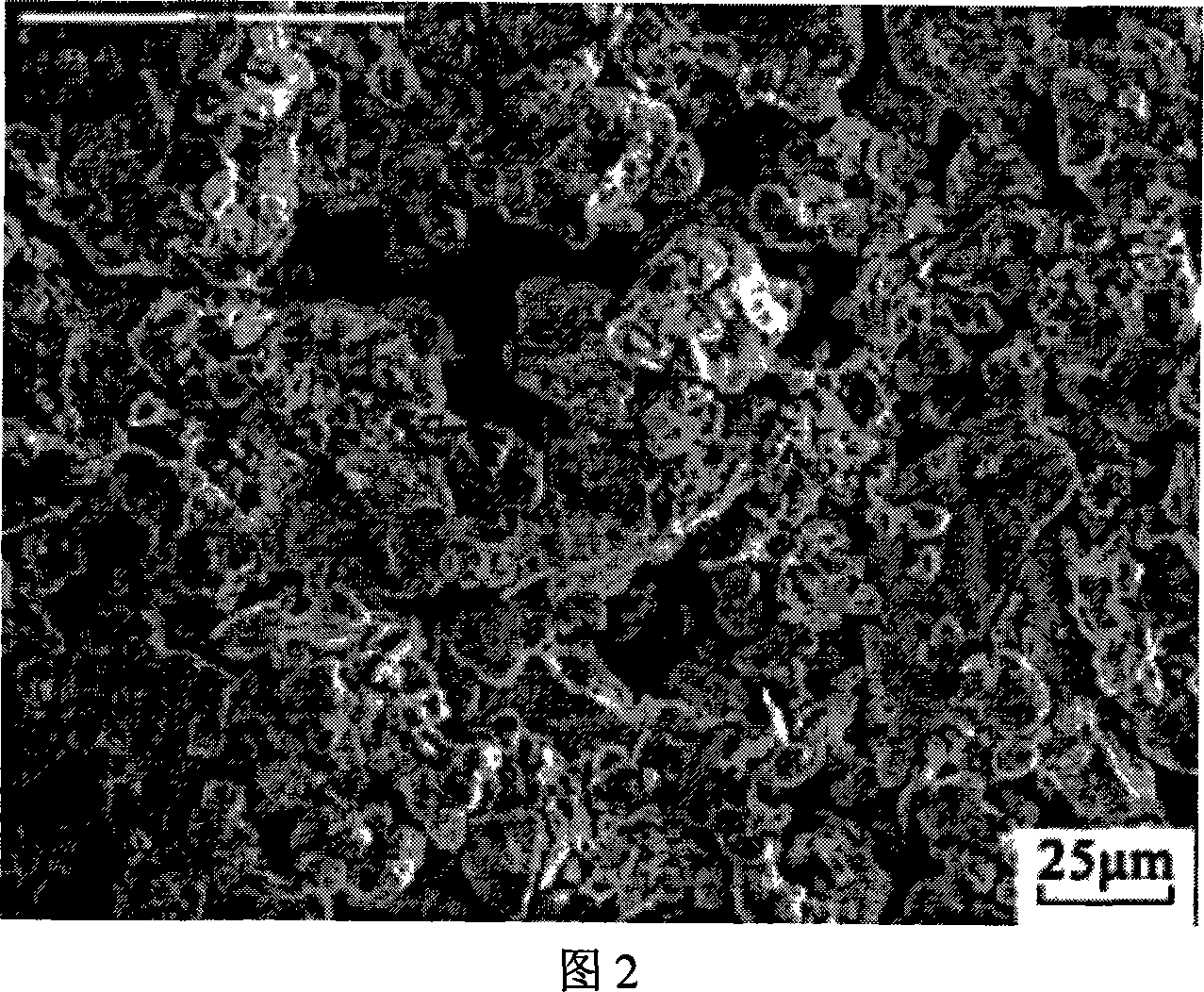

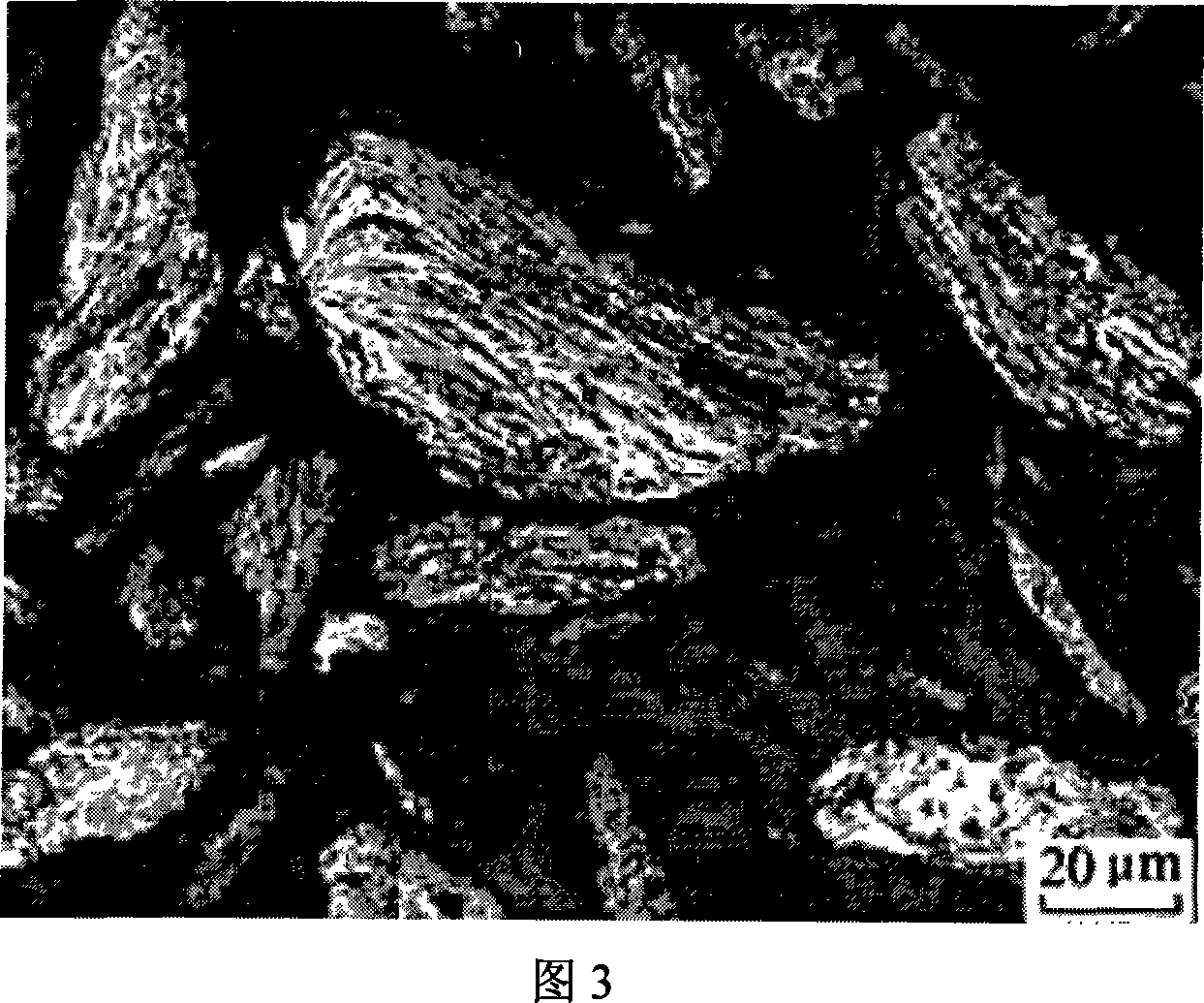

[0041] After the sandblasting pretreatment of the substrate, for the specific intermetallic compound FeAl, select iron powder and aluminum powder in a molar ratio of 1:1 for proportioning. The 1:1 mentioned here is a theoretical ratio, because the intermetallic compound The composition ratio is generally within a certain range corresponding to a certain temperature, so the specific and accurate value of the ratio can be within a certain range according to the coating temperature requirements and the composition ratio of specific intermetallic compounds. Then add 5wt% tungsten carbide ceramic powder to form the initial mixed powder. The three original powders are shown in Figure 1. Put the powder into a ball mill jar with argon as the protective atmosphere, the ratio of ball to material is 5:1, and the speed is 250 rpm. After 30 hours of ball milling, the powder is taken out, and the powder with a particle size of about 10 microns is obtained by sub-sieving. The surface morpholo...

Embodiment 2

[0043] After sandblasting pretreatment of the substrate, for specific intermetallic compounds Fe 3 Al, select iron powder and aluminum powder according to the molar ratio of 3:1 to make a total of 300g, NiTi intermetallic compound particles 100g, alumina ceramic powder 100g to form the initial mixed powder, put it into a ball mill tank and add ethanol as a process control agent , the ratio of ball to material is 10:1, the speed is 200 rpm, the powder is taken out after ball milling for 25 hours, and the powder with a particle size of about 25 microns is obtained by sub-sieving. Nanostructured Fe-Al intermetallic coatings.

Embodiment 3

[0045] After sandblasting pretreatment of the substrate, for the specific intermetallic compound TiAl, select titanium powder and aluminum powder in a molar ratio of 1:1, then add 15wt% boron nitride ceramic powder to form the initial mixed powder, and pack it into Stearic acid is added into the ball mill tank as a process control agent, the ball-to-material ratio is 30:1, and the rotating speed is 150 rpm. It is taken out after ball milling for 40 hours, and the powder with a particle size of about 35 microns is obtained by sub-sieving. The coating is deposited by cold spraying. The coating was heat-treated at 850°C for 15 hours to obtain a nanostructure titanium-aluminum intermetallic compound coating.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com