Mirror large-die-block preparing and producing method of 4Cr16Mo die

A 4cr16mo, 1.4cr16mo technology, used in the production of plastic mold steel and its modules, can solve the problems of difficult processing, inability to have both corrosion resistance and wear resistance, poor welding performance, etc. performance, the effect of excellent corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0060] specific implementation plan

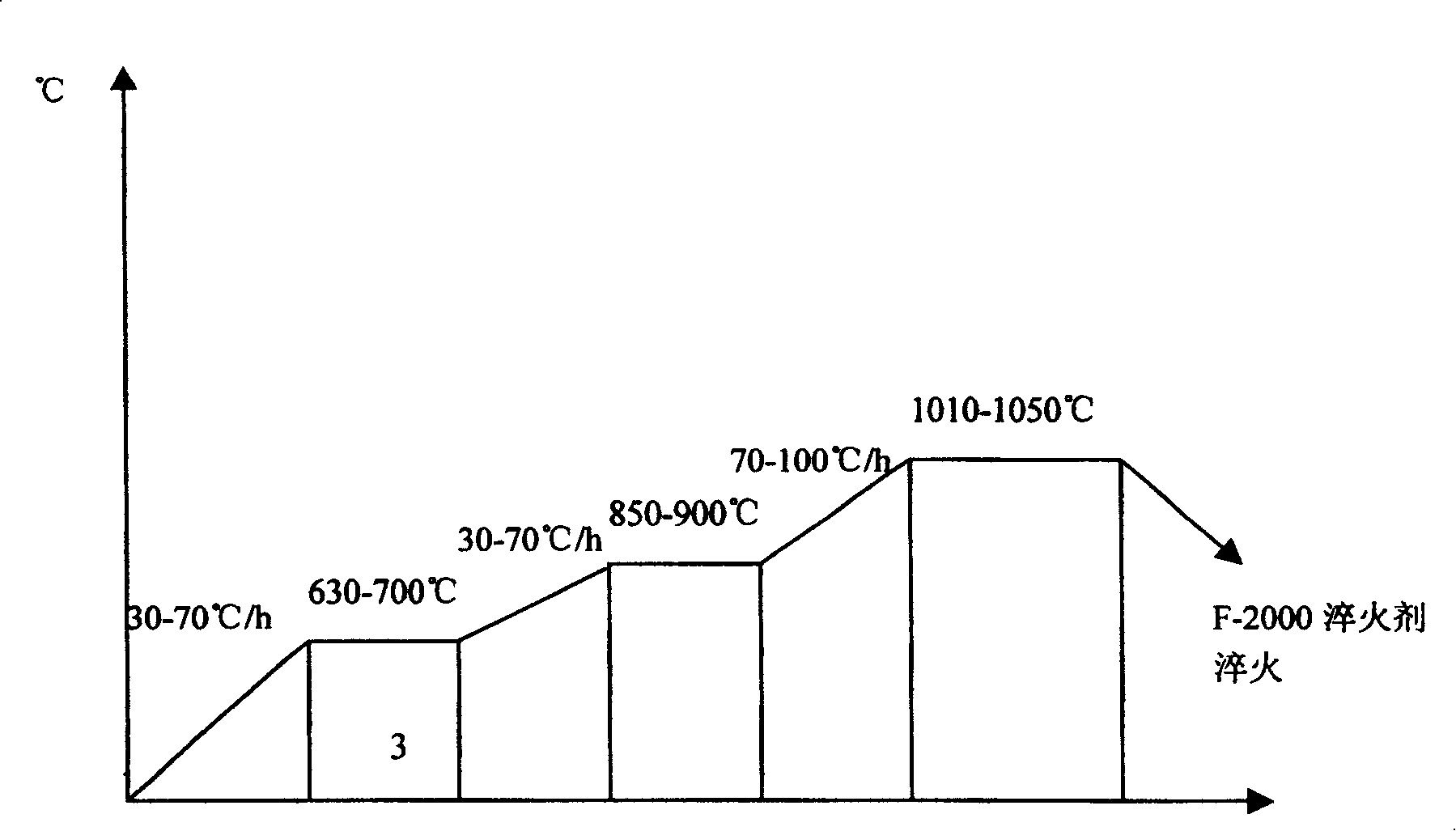

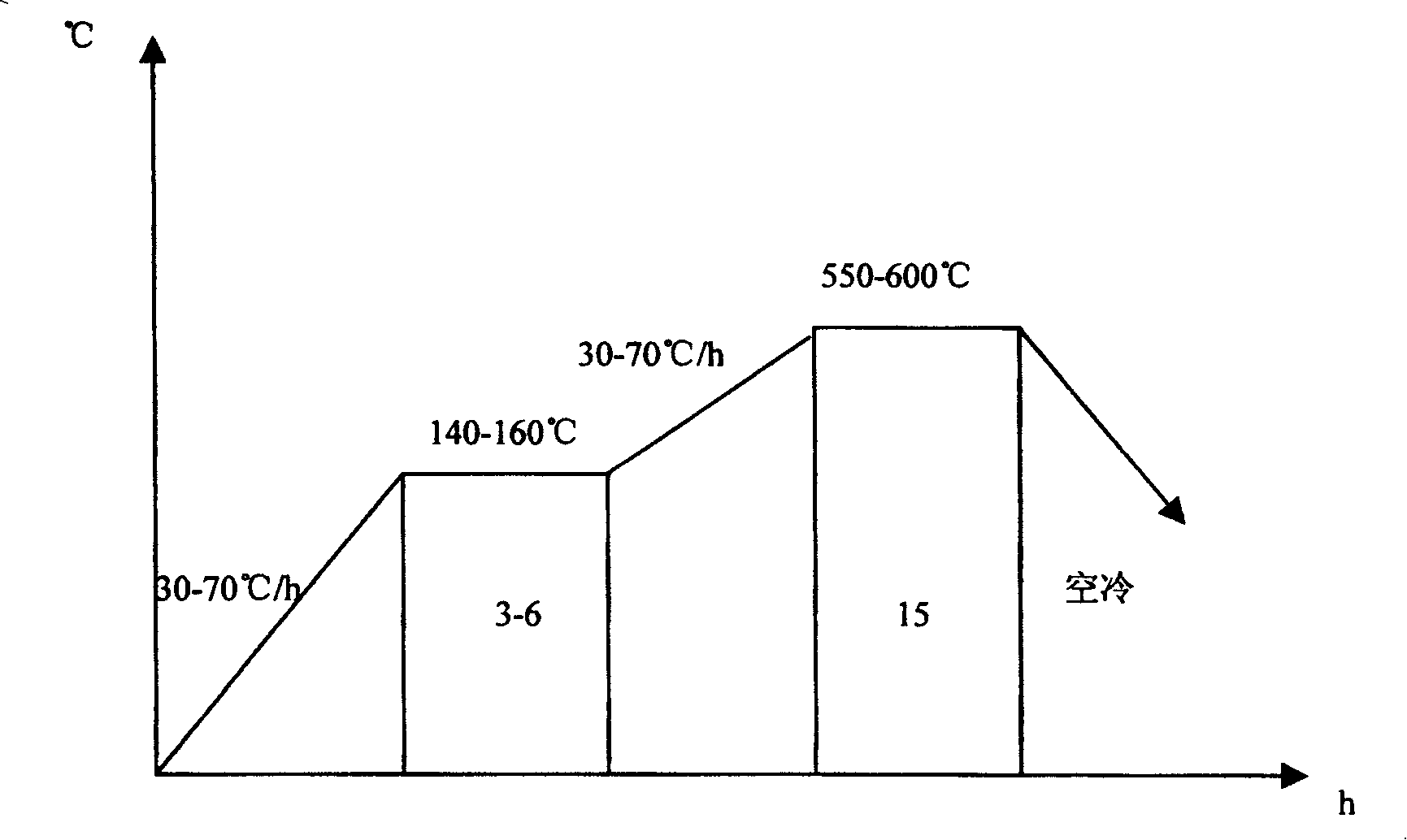

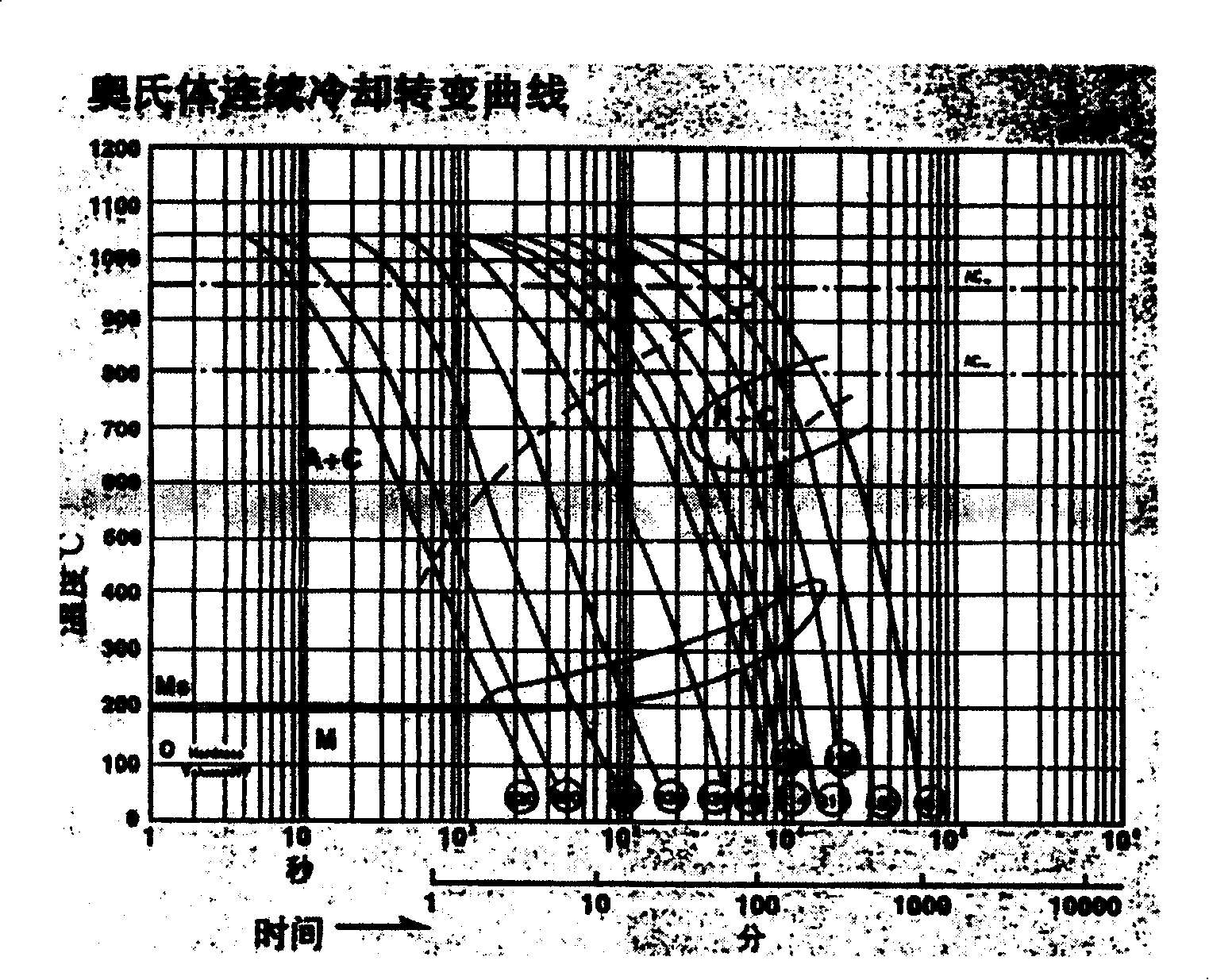

[0061] A certain iron and steel company implements the patent of the invention, and smelts 4 heats of corrosion-resistant and wear-resistant plastic mold steel 4Cr16Mo steel (chemical composition: 0.35-0.41% C, 0.50-0.80% Mn, 0.50-0.80% Si, S≤0.015%, P≤0.025%, 15-16% Cr, 0.10-0.60% Ni, 1.00-1.30% Mo; the rest is Fe. The measured 4Cr16Mo continuous cooling transition curve is: Ac3=960°C, Ac1=800°C, Ms=190°C ); the production preparation method of its large module is to adopt three stages of smelting, forging and quenching and tempering treatment of finished products to produce corrosion-resistant and wear-resistant 4Cr16Mo plastic mold steel (hardness fluctuation after quenching and tempering treatment is less than 4HRC, hardness Large mirror module (thickness: 200-500mm; width: 800-1200mm; length > 2500mm) finished product:

[0062] First, in the smelting stage, the dual refining process of vacuum treatment outside the furnace and electro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com