Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

54results about How to "Variable bending" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Mixed fabric with anti-bacterial function

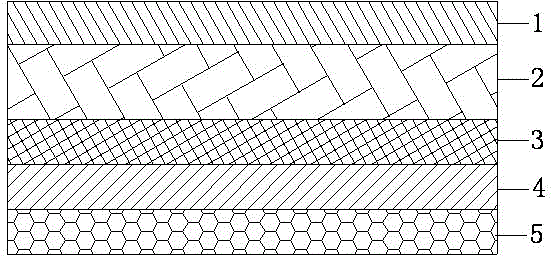

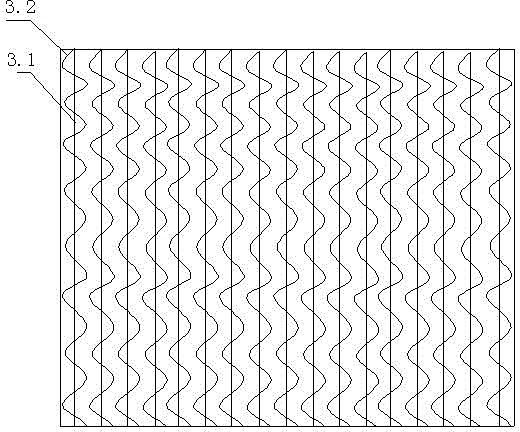

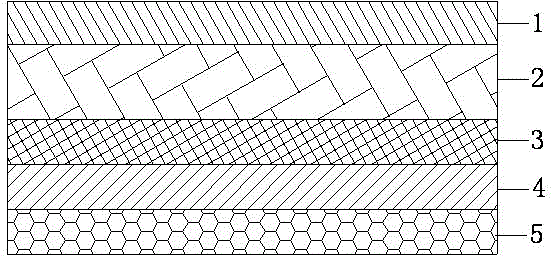

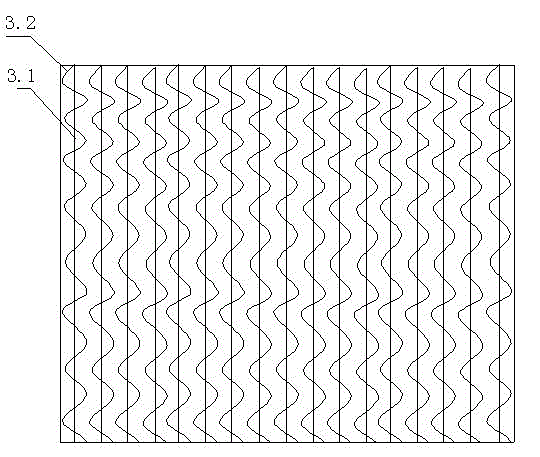

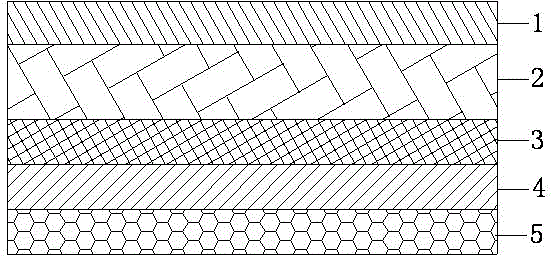

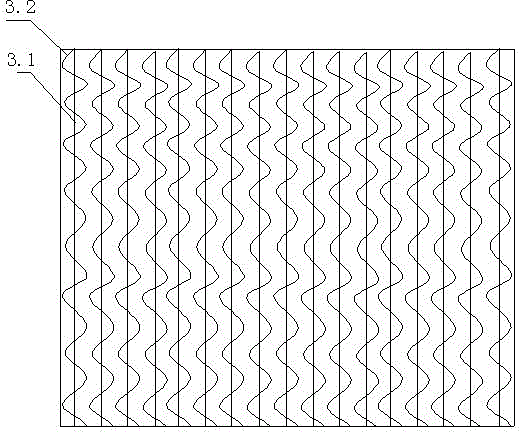

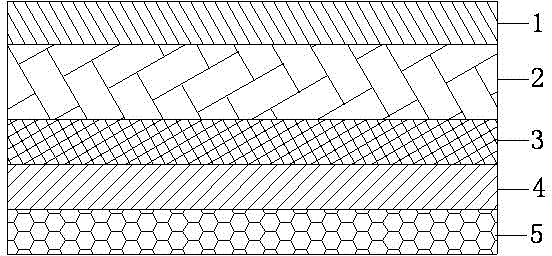

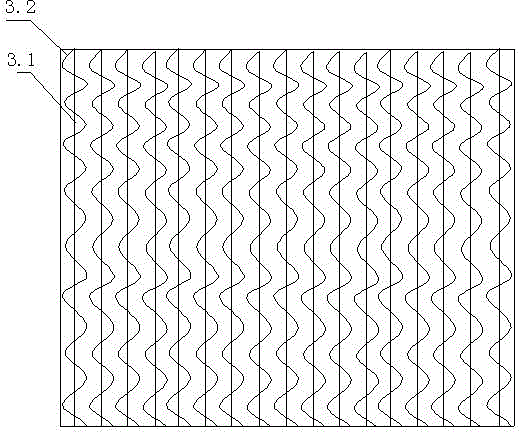

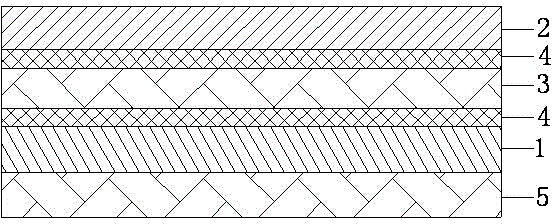

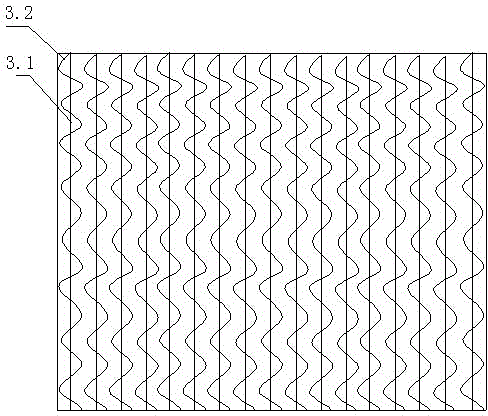

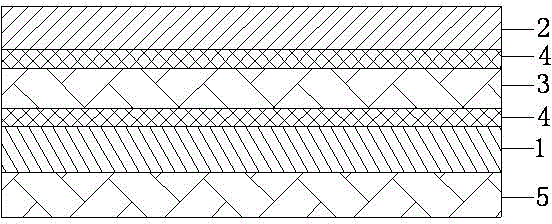

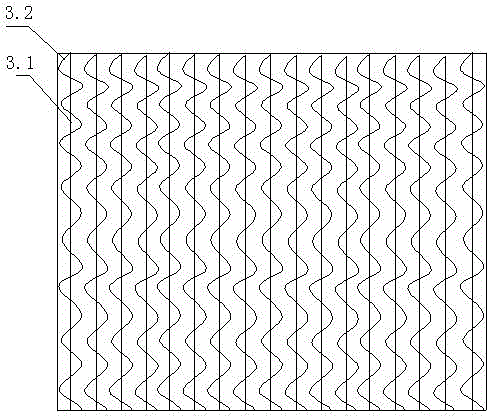

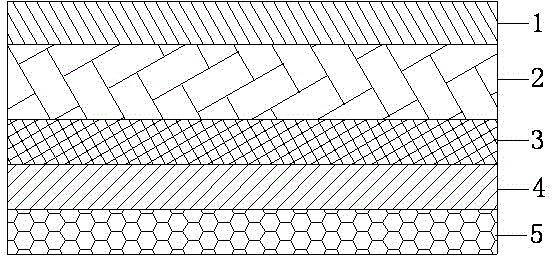

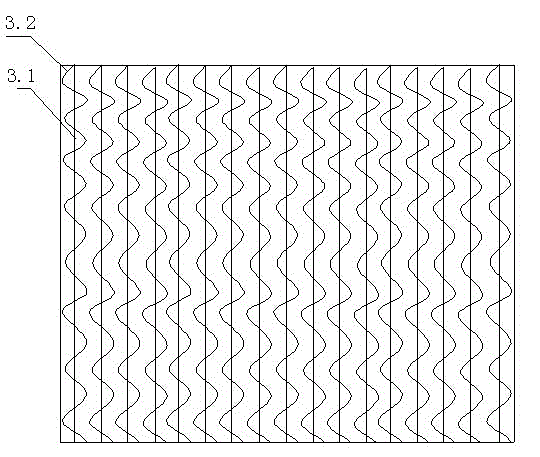

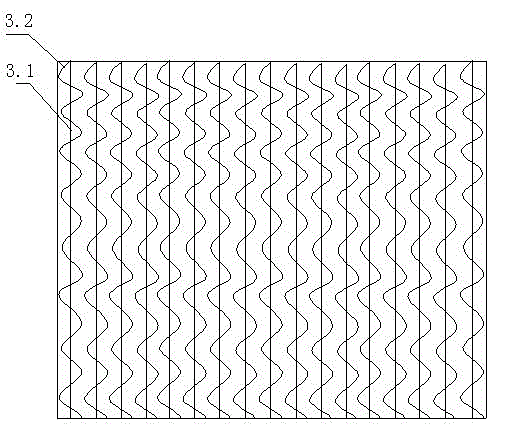

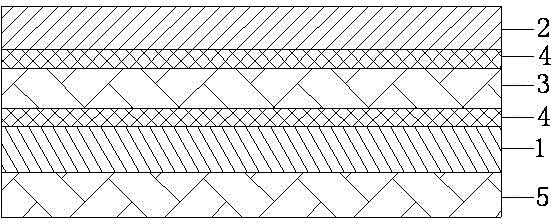

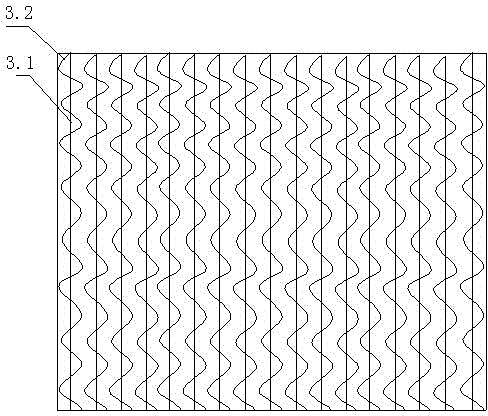

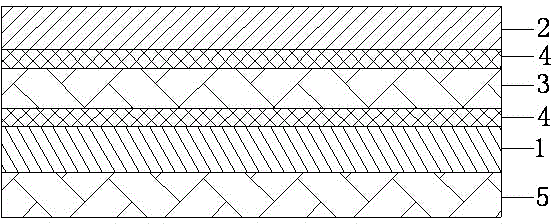

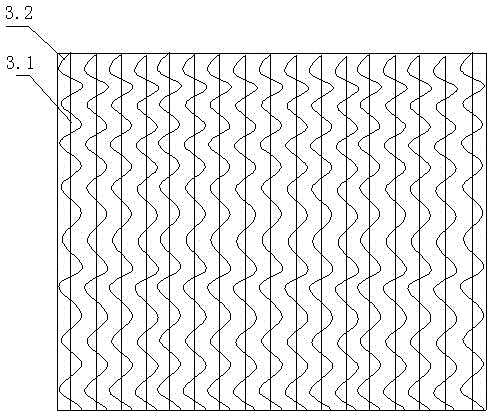

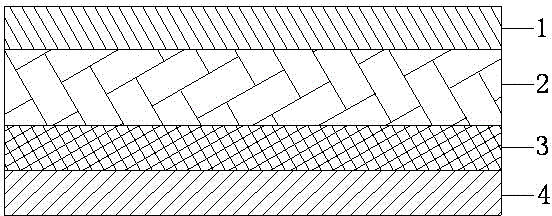

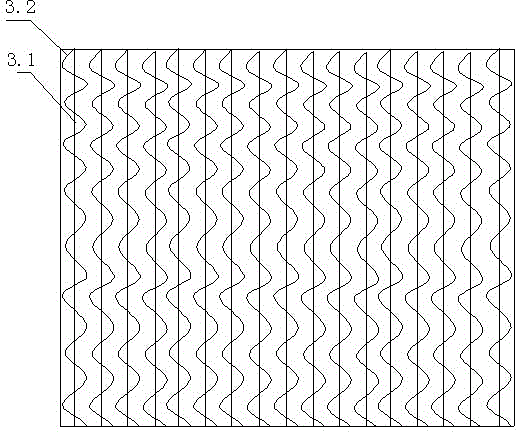

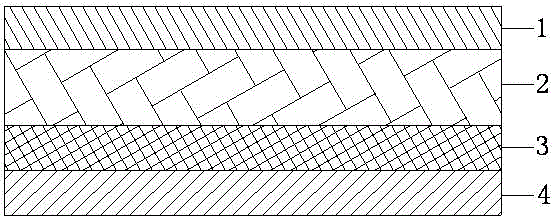

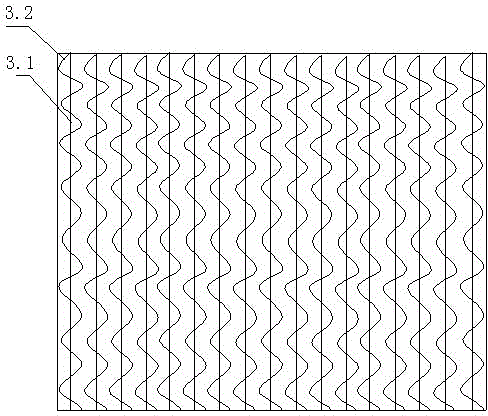

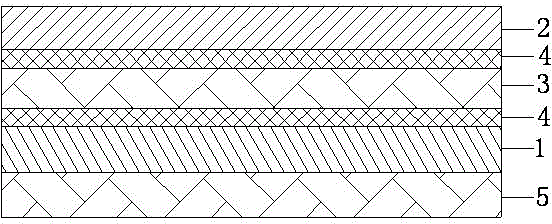

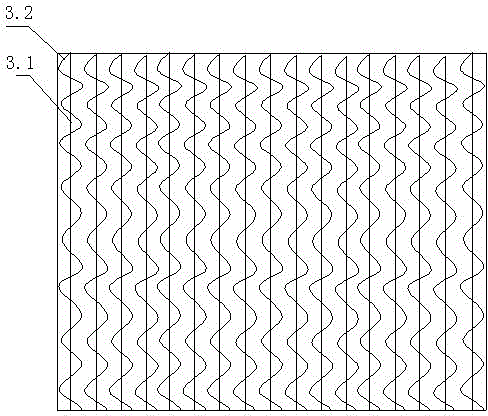

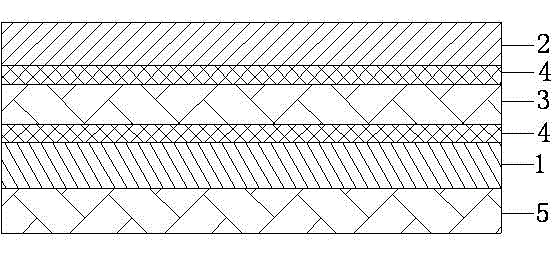

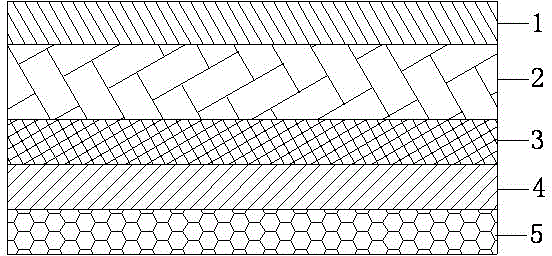

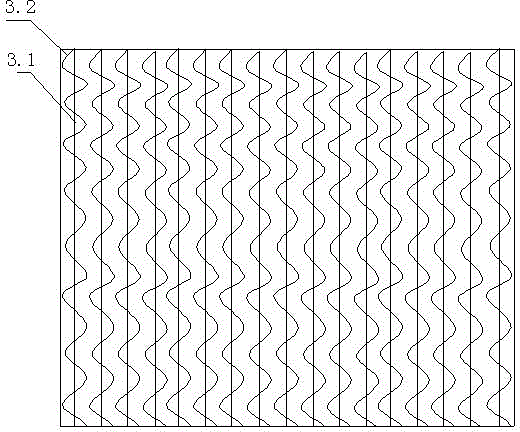

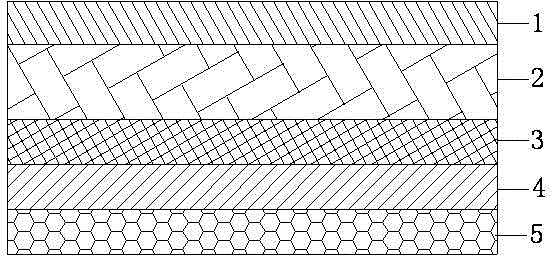

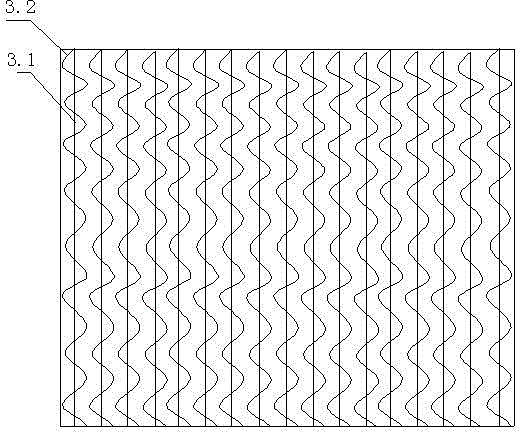

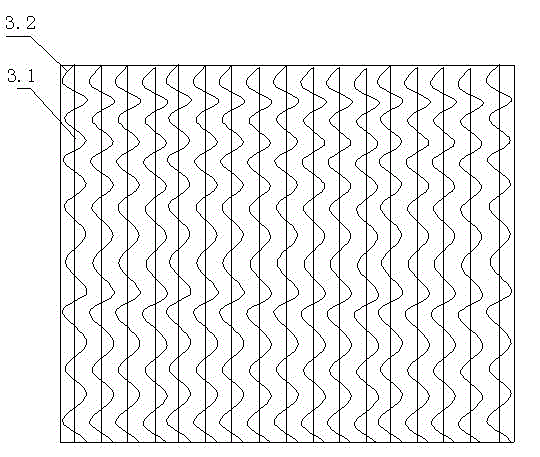

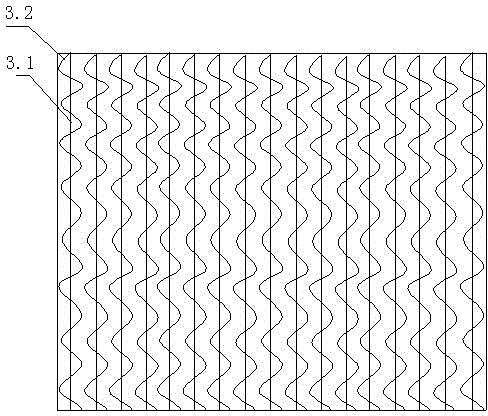

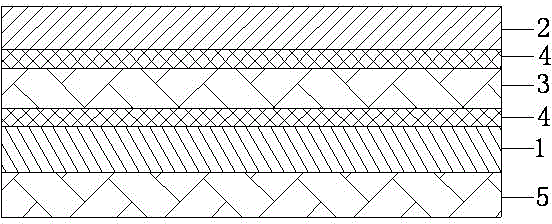

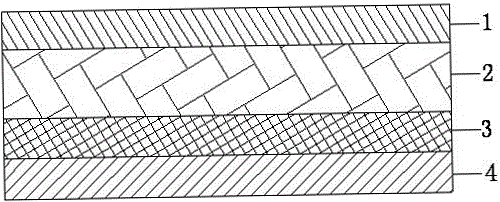

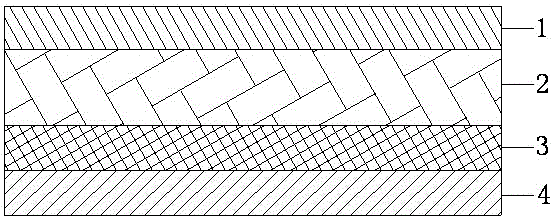

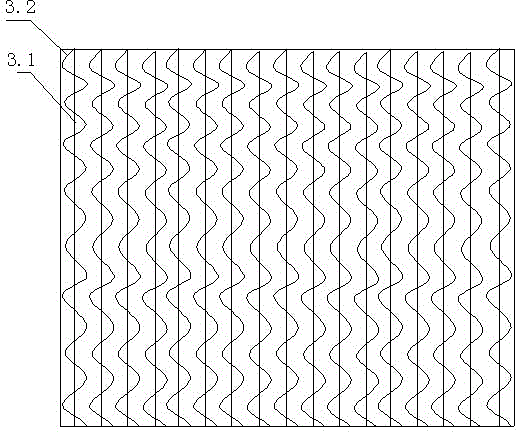

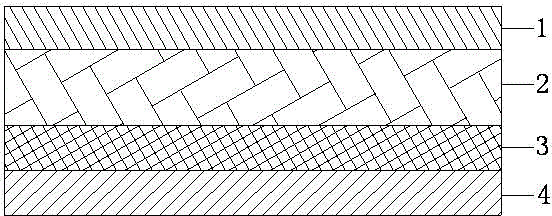

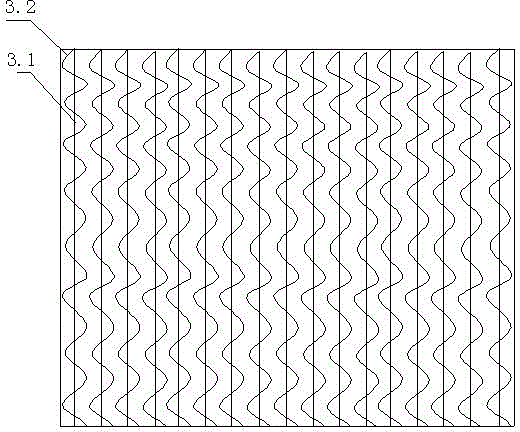

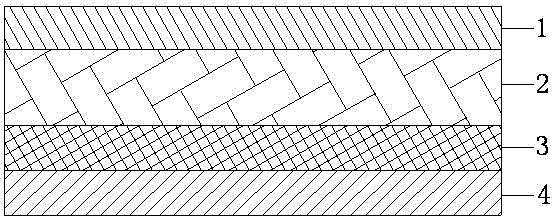

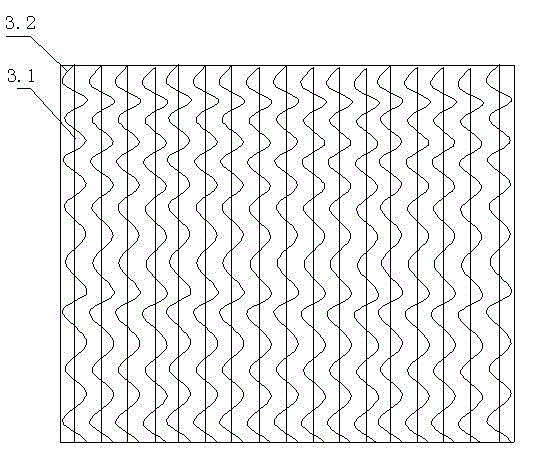

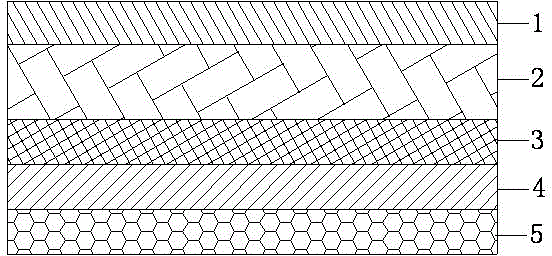

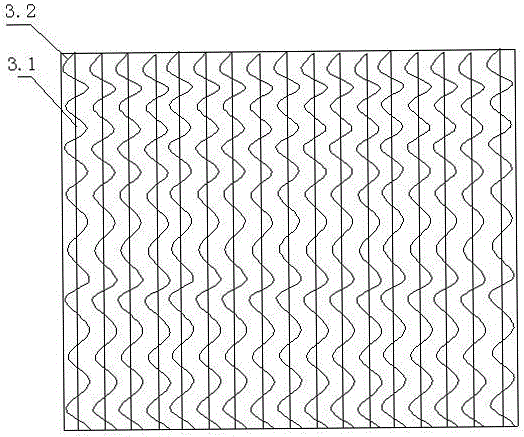

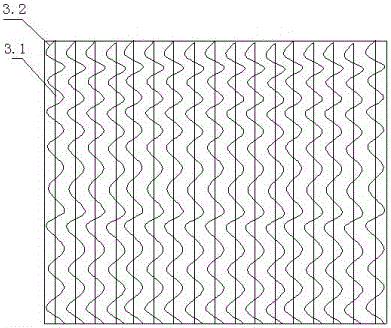

The invention relates to a mixed fabric with the anti-bacterial function. The mixed fabric with the anti-bacterial function comprises a pure cotton fabric (1). A bamboo charcoal fiber layer (2) is arranged under the pure cotton fabric (1). An anti-static layer (3) is arranged under the bamboo charcoal fiber layer (2) and made of core wrapping wire fiber. The core wrapping wire fiber comprises yarn (3.1) and metal wires (3.2) wound on the yarn (3.1). The bottom of the anti-static layer (3) is covered with a layer of blended fabric (4) formed by blending of soybean fiber and pure cotton fiber. A base layer (5) is combined to the lower surface of the blended fabric (4). The base layer is made of woven fabric, and the woven fabric comprises an outer layer, an inner layer and an anti-bacterial layer arranged between the outer layer and the inner layer, wherein the outer layer and the inner layer are ordinary fiber, and the anti-bacterial layer is formed by weaving anti-bacterial fiber. The mixed fabric is not prone to shrinking or wrinkling. By means of the mixed fabric, the anti-bacterial function is achieved.

Owner:JIANGYIN FANRONG YARN DYE FABRIC

Method for preparing multifunctional environment-friendly flame-retardant wall fabrics

InactiveCN107130438AImprove performanceMeet the needs of rich colorsFurniture partsTextiles and paperPolyesterEngineering

The invention provides a method for preparing multifunctional environment-friendly flame-retardant wall fabrics. The method includes steps of providing base cloth; carrying out heat setting on the base cloth, to be more specific, placing the base cloth in a baking oven and baking the base cloth; coating mould-proof flame-retardant coatings on the base cloth after the base cloth is subjected to heat setting, then placing the base cloth in the baking oven and drying the base cloth; carrying out calendering treatment on the base cloth with the coated mould-proof flame-retardant coatings in a calender; adding different types of pigment and pearl powder to the base cloth on the basis of the mould-proof flame-retardant coatings according to different color requirements and ultimately drying the base cloth in the baking oven. The base cloth comprises 80%-100% of polyester fabrics, and holes are reserved in the surfaces of the base cloth. The method has the advantage that environment-friendly flame-retardant colorful multifunctional fabrics can be prepared by the aid of the method.

Owner:CONCORDIA ADVANCED FABRICS SUZHOU

Mixed fabric with good usability

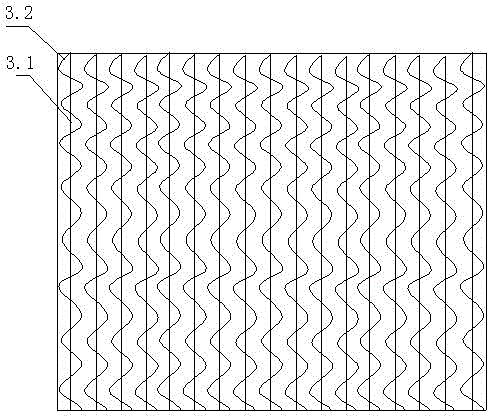

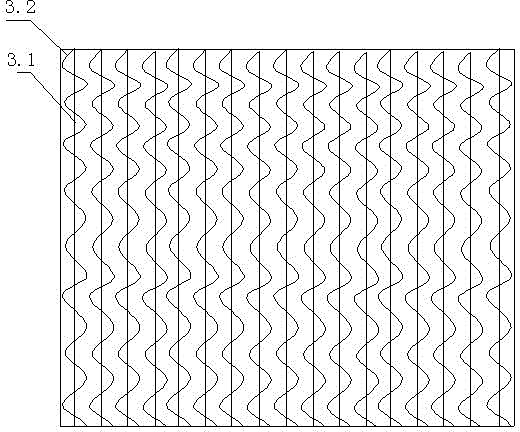

InactiveCN104786566AReasonable structureEasy to useWoven fabricsMetal layered productsYarnBiochemical engineering

The invention relates to a mixed fabric with good usability. The mixed fabric comprises a pure cotton fabric (1); a bamboo charcoal fiber layer (2) is arranged on the lower surface of the pure cotton fabric (1); an anti-static layer (3) is arranged on the lower surface of the bamboo charcoal fiber layer (2), and is made of core spun silk fibers; the core spun silk fibers comprise yarns (3.1) and metal wires (3.2); the metal wire (3.2) are wound on the yarns (3.1); the bottom of the anti-static layer (3) is coated with a layer of blended fabric (4) which is formed by blending of soybean fibers and pure cotton fibers; a base layer (5) is compounded on the lower surface of the blended fabric (4), and is made of a textile; the warps and the wefts of the textile adopt wool fibers and coconut fibers respectively; the diameter of the wool fibers is 9 [mu]m; the diameter of the coconut fibers is 10 [mu]m; the warp density of the textile is 26.6 threads / cm; the weft density of the textile is 31.3 threads / cm. The mixed fabric has low probabilities of shrinkage and crinkle; the adopted fabric construction is reasonable; the service performance is good.

Owner:JIANGYIN HANXIN TEXTILE

Blended fabric with lasting elasticity

The invention relates to blended fabric with lasting elasticity. The blended fabric comprises pure cotton fabric (1), wherein a bamboo charcoal fiber layer (2) is arranged under the pure cotton fabric (1); an anti-static layer (3) is arranged under the bamboo charcoal fiber layer (2), and made of core spun silk fibers; the core spun silk fibers comprise yarn (3.1) and metal silk (3.2); the metal silk (3.2) is wound on the yarn (3.1); a blended fabric layer (4) covers the bottom of the anti-static layer (3), and is formed by blending soybean fibers and pure cotton fibers; a substrate (5) is arranged under the blended fabric layer (4) in a blended manner, and made of fabric; the fabric is formed by interweaving warp silk and tram silk ups and downs; the warp silk is inelastic yarn; the tram silk is elastic yarn, and comprises first warp silk and second warp silk. The blended fabric is lasting in fabric elasticity and particularly good in anti-crease effect.

Owner:JIANGYIN DONGFA GARMENT MAKING

Mixed fabric capable of effectively preventing electromagnetic wave

InactiveCN104786571AAvoid harmGood radiation protectionCellulosic plastic layered productsMetal layered productsYarnEngineering

The invention relates to a mixed fabric capable of effectively preventing an electromagnetic wave. The mixed fabric comprises a pure cotton fabric (1), wherein a bamboo charcoal fiber layer (2) is arranged below the pure cotton fabric (1); an anti-static layer (3) is arranged below the bamboo charcoal fiber layer (2); the anti-static layer (3) is prepared from core-spun yarn fiber; the core-spun yarn fiber comprises yarns (3.1) and metal wires (3.2); the yarns (3.1) are wound by the metal wires (3.2); a layer of blended fabric (4) covers the bottom of the anti-static layer (3); the blended fabric (4) is formed by blending soybean fiber with pure cotton fiber; a basic layer (5) is compounded below the blended fabric (4); the basic layer is prepared from a fabric; the fabric is formed by interweaving warps and wefts; the warps are prepared from nanometer metallic shield fiber yarns, and the wefts are prepared from tencel fiber yarns. The mixed fabric disclosed by the invention is low in possibility of shrinkage and ruffle, good in anti-radiation performance, and capable of effectively preventing a human body from being hurt by the electromagnetic wave.

Owner:JIANGYIN YASHUN GARMENT

Bamboo charcoal fiber fabric with antibacterial function

InactiveCN105644044ASpecial rigidityVariable bendingMetal layered productsYarnBiochemical engineering

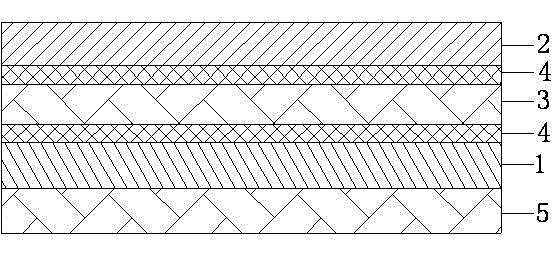

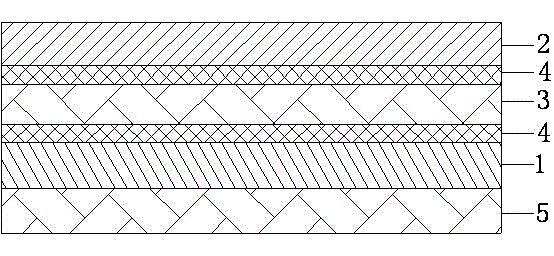

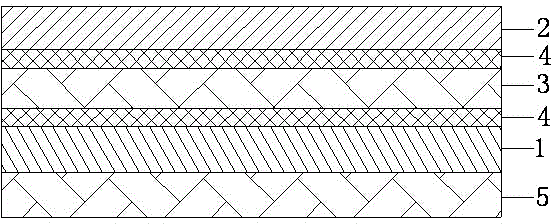

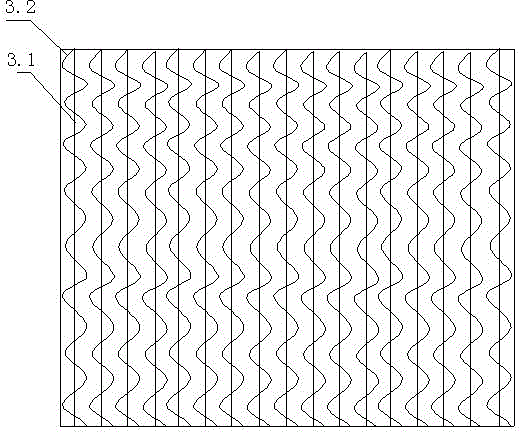

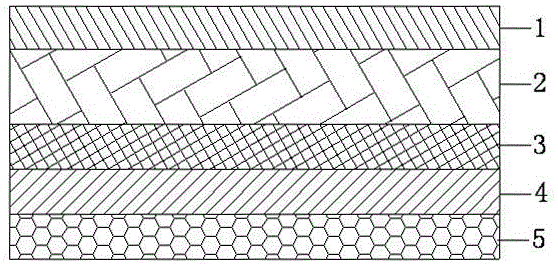

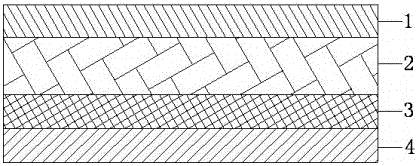

The present invention relates to a bamboo charcoal fiber fabric with antibacterial function, the bamboo charcoal fiber fabric includes bamboo charcoal fiber (1), the upper surface of the bamboo charcoal fiber (1) is covered with a layer of a non-woven fabric (2), the lower surface of the bamboo charcoal fiber (1) is covered with a base layer (5), an anti-static layer (3) is arranged between the non-woven fabric (2) and the bamboo charcoal fiber (1), the anti-static layer (3) is made from core-spun yarn fiber, the core-spun yarn fiber comprises a yarn (3.1) and a metal wire (3.2), and the metal wire (3.2) winds the yarn (3.1). The base layer is made of a fabric, the fabric comprises an outer layer, an inner layer and an antimicrobial layer disposed between the outer and inner layers, the outer and inner layers are ordinary fiber, and the antibacterial layer is woven by antibacterial fiber. The bamboo charcoal fiber fabric is breathable, anti-static and anti-radiation, and has antibacterial function.

Owner:吴建平

Bamboo carbon fiber fabric with good air permeability and comfort

InactiveCN104783380AStrong three-dimensional senseDelicate feelCellulosic plastic layered productsWoven fabricsWoven fabricYarn

The invention relates to a bamboo carbon fiber fabric with good air permeability and comfort. The bamboo carbon fiber fabric comprises bamboo carbon fiber (1), the upper surface of the bamboo carbon fiber (1) is covered with a non-woven fabric (2), the lower surface of the bamboo carbon fiber (1) is covered with a base layer (5), and an anti-static layer (3) is arranged between the non-woven fabric (2) and the bamboo carbon fiber (1). The anti-static layer (3) is made of spun-core yarn fiber which comprises a yarn (3.1) and a metal yarn (3.2), wherein the yarn (3.1) is wound by the metal yarn (3.2). The base layer is made of a fabric which is formed by tatting viscose filaments and silk in a 1 / 1 tabby mode, wherein the monofilament diameter of the viscose filaments ranges from 0.8 microns to 1.5 microns. The bamboo carbon fiber fabric has the advantages of air permeability, anti-static performance and anti-radiation performance. The bamboo carbon fiber fabric is good in air permeability and comfort.

Owner:JIANGYIN YASHUN GARMENT

Cold-resistant velvet fabric

InactiveCN104783366ASimple fabric structureAgainst the coldSynthetic resin layered productsProtective garmentCompound (substance)Yarn

The invention relates to a cold-resistant velvet fabric. The cold-resistant velvet fabric comprises velvet cloth (1). A sponge layer (2) is arranged under the velvet cloth (1). An antistatic layer (3) is arranged under the sponge layer (2) and made of core spun silk fibers. The fibers comprise yarns (3.1) and metal wires (3.2). The metal wires (3.2) are wound around the yarns (3.1). A base layer (4) is arranged under the antistatic layer (3). The base layer (4) is made of a fabric. The fabric is formed by closely combining a fabric layer, a warmth keeping layer, a cavity layer and a surface layer sequentially from inside to outside; the surface layer is formed by interweaving yarns containing conductive fibers and common-fiber yarns, the common fibers are cotton fibers, jute fibers, wool fibers, silk fibers or chemical fibers, and the warmth-keeping layer is made of sponges. The cold-resistant velvet fabric is elegant in color and gloss, gorgeous, sumptuous, strong, resistant to abrasion, not prone to deformation, high in elasticity, capable of absorbing dampness, breathable and resistant to coldness.

Owner:JIANGYIN HANXIN TEXTILE

Blended fabric with better dimensional stability

InactiveCN105615081ABig spaceIncrease elasticitySynthetic resin layered productsWoven fabricsPolyesterMetal filament

The invention relates to blended fabric with better dimensional stability. The blended fabric comprises pure cotton fabric (1), wherein a bamboo charcoal fiber layer (2) is arranged under the pure cotton fabric (1); an anti-static layer (3) is arranged under the bamboo charcoal fiber layer (2) and is made of core spun silk fibers, the core spun silk fibers comprise yarn (3.1) and metal filaments (3.2), and the yarn (3.1) is wound with the metal filaments (3.2); the bottom of the anti-static layer (3) is covered with a blended cloth layer (4) which is prepared from soybean fibers and pure cotton fibers through blending, and a base layer (5) is compounded under the blended cloth layer (4). The base layer is made of fabric, the fabric is formed through interweaving of warp yarn and weft yarn, the warp yarn and the weft yarn are arranged in a two-up and two-down mode, and the warp yarn adopts 50D / 72F polyester drawn textured yarn; the blended yarn is not prone to shrinking and creasing and has the better dimensional stability.

Owner:JIANGYIN FANGLONG FINERY HANDICRAFT

Velvet fabric with strong ventilation and sweat-permeation capability

The invention relates to a velvet fabric with strong ventilation and sweat-permeation capability. The velvet fabric comprises velvet cloth (1), wherein a sponge layer (2) is arranged under the velvet cloth (1); an antistatic layer (3) is arranged under the sponge layer (2); the antistatic layer (3) is made of core-spun yarn fibers; the fibers comprise yarns (3.1) and metal wires (3.2); the metal wires (3.2) are wound on the yarns (3.1); and a base layer (4) is arranged under the antistatic layer (3). The base layer is made of a textile and the textile is formed by interweaving warps and wefts; the warps and the wefts are in an up-down plain weave pattern; the wefts comprise first wefts and second wefts; the first wefts and the second wefts are arrayed at the ratio of 1 to 1; the warps are made from PET fibers; the first wefts are made from viscose fibers; and the second wefts are made from moisture-absorption and sweat-permeation fibers. The velvet fabric has elegant color and luster, is gorgeous and is firm and wearable, is not easy to deform, has elasticity and has the moisture-absorption and ventilation functions. The velvet fabric has the strong ventilation and sweat-permeation capability.

Owner:JIANGYIN FANRONG YARN DYE FABRIC

Reasonable-structure bamboo charcoal fiber fabric

InactiveCN104786578AReasonable structureEasy to useSynthetic resin layered productsMetal layered productsRadiation resistantMetal

The invention relates to reasonable-structure bamboo charcoal fiber fabric which comprises bamboo charcoal fiber (1), wherein the upper surface of the bamboo charcoal fiber (1) is coated with a non-woven fabric layer (2); the lower surface of the bamboo charcoal fiber (1) is coated with a base course (5); an anti-static layer (3) is arranged between the non-woven fabric layer (2) and the bamboo charcoal fiber (1) and is made of core-spun silk fiber; the core-spun silk fiber comprises yarns (3.1) and metal wires (3.2); the metal wires (3.2) are wound on the yarns (3.1). The base course comprises a textile; the textile warp yarns and weft yarns adopt chinlon 6 fiber and tussah silk fiber respectively; the diameter of the chinlon 6 fiber is 9 [Mu] m, and the dtex of the chinlon 6 fiber is 398 dtex; the diameter of the tussah silk fiber is 4 [Mu] m, and the dtex of the tussah silk fiber is 356 dtex; the warp density of the textile is 22.3 pieces / cm, and the weft density of the textile is 20.2 pieces / cm. The reasonable-structure bamboo charcoal fiber fabric has the air permeable, anti-static and radiation-resistant effects. The adopted textile is reasonable in structure and excellent in usability.

Owner:江阴市华凯针织制衣有限公司

Bamboo charcoal fiber fabric with strong breathability and strong sweat-releasing property

InactiveCN105686178AStrong three-dimensional senseSpecial rigidityWoven fabricsProtective garmentRadiation resistanceViscose fiber

The invention relates to a bamboo charcoal fiber fabric with strong breathability and strong sweat-releasing property. The bamboo charcoal fiber fabric comprises bamboo charcoal fibers (1), wherein a layer of non-woven fabric (2) covers the bamboo charcoal fibers (1), a base layer (5) is covered by the bamboo charcoal fibers (1), an anti-static layer (3) is arranged between the non-woven fabric (2) and the bamboo charcoal fibers (1), and is prepared by core-spun yarn fibers, the core-spun yarn fibers comprise yarns (3.1) and metal wires (3.2), and the metal wires (3.2) wind the yarns (3.1). The base layer is prepared by a textile, the textile is formed by interweaving warp yarns and weft yarns in a plain structure with the arrangement manner of one warp yarn on the upper part and one weft yarn on the lower part, the weft yarns comprise first weft yarns and second weft yarns which are arranged according to the ratio of 1 to 1, the warp yarns adopt PET fibers, and the first weft yarns adopt viscose fibers. The bamboo charcoal fiber fabric has the effects of breathability, static electricity resistance and radiation resistance. The bamboo charcoal fiber fabric has strong breathability and strong sweat-releasing property.

Owner:江苏迈克王科技有限公司

Layered bamboo carbon fiber fabric

The invention relates to a layered bamboo carbon fiber fabric. The layered bamboo carbon fiber fabric comprises bamboo carbon fibers (1), a non-woven fabric (2) covers upper surfaces of the bamboo carbon fibers (1), a base layer (5) covers lower surfaces of the bamboo carbon fibers (1), an antistatic layer (3) is arranged between the non-woven fabric (2) and the bamboo carbon fibers (1), the antistatic layer (3) is prepared from core-spun yarn fibers, the core-spun yarn fiber comprises yarn (3.1) and metal wires (3.2) and the metal wires (3.2) enwind the yarn (3.1). The base layer is prepared from a fabric, the surface of the fabric is provided with several three-dimensional stripes, the several three-dimensional stripes are horizontally arranged at the equal intervals, the three-dimensional stripe has a L-shaped cross section, the previous three-dimensional stripe is connected to the adjacent next three-dimensional stripe and the joint is located at the bottom of the previous three-dimensional stripe and is fixed to the fabric through a wire. The layered bamboo carbon fiber fabric has permeability, static resistance and radiation resistance. The three-dimensional stripes with the joints improve fabric layering.

Owner:WUXI HUALIAN PLASTIC PROD CO LTD

Antifouling breathable velvet fabric

The invention relates to an antifouling breathable velvet fabric. The fabric comprises velvet cloth (1). A sponge layer (2) is arranged below the velvet cloth (1). An antistatic layer (3) is arranged below the sponge layer (2). The antistatic layer (3) is prepared with core-spun fiber. The fiber comprises yarn (3.1) and metal filament (3.2). The metal filament (3.2) is wound on the yarn (3.1). A base layer (4) is arranged below the antistatic layer (3). The base layer is prepared with textile. A fluorine monomer aqueous polyurethane coating layer is coated on the surface of the textile. The fabric provided by the invention has an elegant shade, and is luxuriant, firm, and wear-resistant. The fabric is not prone to deformation. The fabric is rich in elasticity. The fabric can absorb moisture, and is breathable. The fabric is antifouling and breathable.

Owner:李士清

Fluorescent and luminous velvet fabric

InactiveCN104802487AEasy to manufactureLight structureSynthetic resin layered productsClothingsYarnFiber

The invention relates to a fluorescent and luminous velvet fabric which includes velvet cloth (1), wherein a sponge layer (2) is arranged under the velvet cloth (1); an antistatic layer (3) is arranged under the sponge layer (2); the antistatic layer (3) is made of core-spun yarn fibers; the fibers include yarns (3.1) and metal wires (3.2); the metal wires (3.2) are wound on the yarns (3.1); a base layer (4) is arranged under the antistatic layer (3) and made of textile fabric; the textile fabric includes a fabric body, as well as an intermediate layer and a luminous body both of which are arranged on the fabric body in sequence; an adhesive layer is arranged on the back face of the luminous body, and a fluorescent surface layer is arranged on the front face of the luminous body. The fluorescent and luminous velvet fabric provided by the invention is gentle in color and light, elegant, firm and anti-wear, not liable to deformation, high in resilience, and good in moisture absorption and air permeability; the velvet fabric is fluorescent and luminous.

Owner:JIANGYIN CHUNLAN TEXTILE

Bamboo carbon fiber fabric with high comfort level

InactiveCN105619927AReasonable structural designImprove breathabilityYarnMetal layered productsYarnIrradiation

The invention relates to a bamboo carbon fiber fabric with high comfort level. The bamboo carbon fiber fabric comprises bamboo carbon fiber (1); the upper surface of the bamboo carbon fiber (1) is coated with a layer of non-woven fabric (2), and the lower surface is coated with a layer of base layer (5); an anti-static layer (3) is arranged between the non-woven fabric (2) and the bamboo carbon fiber (1); the anti-static layer (3) is prepared from core-spun yarn fiber; the core-spun yarn fiber comprises yarn (3.1) and metal wires (3.2); the yarn (3.1) is winded by the metal wires (3.2); the base layer is prepared from a fabric, and the fabric is composed of first yarn and second yarn; the first yarn and the second yarn circles in sequence along the parallel direction of the fabric, and interlaces sequentially and alternately in the longitudinal direction so as to obtain the fabric with a weft knitted structure; the front surface of the fabric is provided with convex strips; and the convex strips are obtained via knitting of the first yarn and the second yarn. The bamboo carbon fiber fabric possesses gas permeability, antistatic properties, and irradiation resistance. Comfort level of the bamboo carbon fiber fabric is high.

Owner:苏光明

Bamboo charcoal fiber fabric with persistent elasticity

InactiveCN104802468ASpecial rigidityVariable bendingWoven fabricsMetal layered productsMetal filamentBiochemical engineering

The invention relates to bamboo charcoal fiber fabric with persistent elasticity. The bamboo charcoal fiber fabric comprises bamboo charcoal fiber (1), wherein a non-woven fabric layer (2) is arranged above the bamboo charcoal fiber (1) in a covered manner; a base layer (5) is arranged below the bamboo charcoal fiber (1) in a covered manner; an anti-static layer (3) is further arranged between the non-woven fabric layer (2) and the bamboo charcoal fiber (1) and is prepared from core-spun fiber which comprises yarn (3.1) and metal filaments (3.2) wound around the yarn (3.1); the base layer is prepared from textile fabric which is woven by warp yarn and weft yarn in an up and down manner, the warp yarn adopts non-elastic yarn, the weft yarn adopts elastic yarn and comprises first weft yarn and second weft yarn which are double weft, and the warp yarn, the first weft yarn and the second weft yarn are woven in an up and down manner to form a five-heddle backed weave structure. The bamboo charcoal fiber fabric has the effects of breathability, anti-static performance and radiation resistance; the fabric has persistent elasticity and a very high anti-crease effect.

Owner:JIANGYIN GUORUN TEXTILE RAW MATERIALS SALES

Bamboo charcoal fiber fabric capable of preventing electromagnetic waves effectively

InactiveCN104859216AAvoid harmGood radiation protectionCellulosic plastic layered productsMetal layered productsYarnEngineering

The invention relates to a bamboo charcoal fiber fabric capable of preventing electromagnetic waves effectively. The fabric comprises bamboo charcoal fibers (1), the top of the bamboo charcoal fibers (1) is covered with a layer of non-woven cloth (2), and the bottom of the bamboo charcoal fibers (1) is covered with a base layer (5). An anti-static layer (3) is further arranged between the non-woven cloth (2) and the bamboo charcoal fibers (1) and is made of core spun silk fibers which comprise yarns (3.1) and metal wires (3.2). The metal wires (3.2) are wound on the yarns (3.1), and a base layer (4) is arranged under the anti-static layer (3) and is made of a textile. The textile is formed by interweaving of warps and wefts. The warps are composed of nano metal shielding fiber yarns, and the wefts are composed of tencel fiber yarns. The fabric has the advantages of being breathable, anti-static and anti-radiation, good in radiation resistance and capable of preventing hurt to human bodies from electromagnetic waves effectively.

Owner:JIANGYIN CHENGXIN SPECIAL PRINTING

Blended fabric with good layering effect

InactiveCN105619933AStrong sense of hierarchyStrong three-dimensional senseMetal layered productsYarnAntistatic agent

The invention relates to a blended fabric with a good layering effect. The fabric comprises pure cotton fabric (1). A bamboo charcoal fiber layer (2) is arranged below the pure cotton fabric (1). An antistatic layer (3) is arranged below the bamboo charcoal fiber layer (2). The antistatic layer (3) is prepared with core-spun fiber. The fiber comprises yarn (3.1) and metal filament (3.2). The metal filament (3.2) is wound on the yarn (3.1). A layer of blended fabric (4) is coated on the bottom of the antistatic layer (3). The blended fabric (4) is prepared by blending soybean fiber and pure cotton fiber. A base layer (5) is compounded under the blended fabric (4). The base layer is prepared with textile. A non-woven fabric surface layer is arranged on the surface of the textile. A plurality of small textile blocks are arranged between the textile layer and the non-woven fabric surface layer. The fabric provided by the invention is not prone to shrinkage and wrinkle. The fabric has a good layering effect.

Owner:李士清

Blended fabric with reasonable structure

InactiveCN104799459ASpecial rigidityVariable bendingWoven fabricsProtective garmentPolyamideEngineering

The invention relates to a blended fabric with a reasonable structure. The blended fabric comprises a pure cotton fabric (1), wherein a bamboo charcoal fiber layer (2) is arranged on the lower face of the pure cotton fabric (1); an antistatic layer (3) is also arranged on the lower face of the bamboo charcoal fiber layer (2) and is made of core-spun silk fibers; the core-spun silk fibers comprise yarns (3.1) and metal wires (3.2); the metal wires (3.2) wind the yarns (3.1); the bottom of the antistatic layer (3) is coated with a layer of blended fabric (4); the blended fabric (4) is formed by blending soybean fibers and pure cotton fibers; a base layer (5) is compounded on the lower face of the blended fabric (4) and is made of fabric; warp yarns and weft yarns of the fabric respectively adopt polyamide 6 fibers and silk tussah fibers; the diameters of the polyamide 6 fibers are 9mu m, and the fineness of the polyamide 6 fibers is 398dtex; the diameters of the silk tussah fibers are 4mu m, and the fineness of the silk tussah fibers is 356dtex; the warp density of the fabric is 22.3 piece / cm, and the weft density of the fabric is 20.2 piece / cm. The blended fabric disclosed by the invention is not easy to shrink or wrinkle; the fabric adopted by the invention is reasonable in structure and is good in use performance.

Owner:JIANGYIN GUORUN TEXTILE RAW MATERIALS SALES

Mixed fabric of textile fabric with decorative pattern

InactiveCN104856312ANo need to dyeSpecial rigiditySynthetic resin layered productsWoven fabricsEngineeringBrightness perception

The invention relates to a mixed fabric of a textile fabric with a decorative pattern, which comprises a pure cotton fabric (1), wherein a bamboo charcoal fiber layer (2) is set below the pure cotton fabric (1); an anti-static electricity layer (3) is set below the bamboo charcoal fiber layer (2); the anti-static electricity layer (3) is made of coated core silk fiber; the coated core silk fiber comprises yarn (3.1) and a metal wire (3.2); the metal wire (3.2) is wound on the yarn (3.1); the bottom of the anti-static electricity layer (3) is covered with a piece of blended cloth (4); the piece of the blended cloth (4) is blended by soybean fiber and pure cotton fiber; and a basic layer (5) is composited below the piece of the blended cloth (4). The basic layer is made of fabric; the fabric is interwoven by warp yarn and weft yarn; the texture structure is third one interwoven twill texture structure; the warp yarn is 800 D dacron FDY with super brightness; the weft yarn is 800 D dacron FDY with super brightness; the density of the warp yarn is 25 per centimeter and the density of the weft yarn is 16 per centimeter; and the warp yarn is twisted 180 per meter. The mixed fabric is not easily contracted and crumpled; and the mixed fabric provided herein is relatively harder.

Owner:JIANGYIN CHENGXIN SPECIAL PRINTING

Bamboo charcoal fiber fabric with good dimension stability

InactiveCN105639792ABig spaceIncrease elasticitySynthetic resin layered productsWoven fabricsYarnMetal filament

The invention relates to a bamboo charcoal fiber fabric with good dimension stability; the bamboo charcoal fiber fabric comprises bamboo charcoal fibers (1); the bamboo charcoal fibers (1) is covered by a non-woven fabric (2); a base layer (5) is arranged under the bamboo charcoal fibers (1); an antistatic layer (3) is arranged between the non-woven fabric (2) and the bamboo charcoal fibers (1), and formed by core-spun silk fibers; the core-spun silk fibers comprise yarns (3.1) and metal filaments (3.2) wrapping the yarns (3.1); the base layer is formed by cloth, and the cloth is formed by mutually interlacing warp yarns with filling yarns, wherein the warp yarns and the filling yarns are two-up two-down arranged; the warp yarn refers to 50D / 72F terylene low elasticity filament; the filling yarn is 50D / 36F terylene low elasticity filament; the warp yarn and the filling yarn are twill structures. The bamboo charcoal fiber fabric is good in permeability, antistatic and radiation hardening effect, and good in dimension stability.

Owner:JIANGYIN YONGLONG PLASTICS

Bamboo charcoal fiber shell fabric with fabric provided with patterns

InactiveCN104790095ANo need to dyeSpecial rigidityLayered productsWoven fabricsRadiation resistantEngineering

The invention relates to a bamboo charcoal fiber shell fabric with fabric provided with patterns. The bamboo charcoal fiber shell fabric with the fabric provided with the patterns comprises bamboo charcoal fiber (1), the upper side of the bamboo charcoal fiber (1) is covered with a layer of non-woven fabric (2), the lower side of the bamboo charcoal fiber (1) is covered with a base layer (5), an anti-static layer (3) is further arranged between the non-woven fabric (2) and the bamboo charcoal fiber (1), the anti-static layer (3) is made of core-spun yarn fibers, the core-spun yarn fibers comprise yarns (3.1) and metal wires (3.2), and the metal wires (3.2) is wound by the yarns (3.1). The base layer is made of fabric, the fabric is formed by interweaving warp yarns and weft yarns, the organization structure is of a 3 / 1 interweaving twill-weave structure, the warp yarns adopt 800D dacron super bright FDY, the weft yarns adopt 800D dacron super bright FDY, the warp density is 25 yarns / cm, the weft density is 16 yarns / cm, and Z twist yarns are added into the warp yarns at the frequency of 180 yarns / m. The bamboo charcoal fiber shell fabric with the fabric provided with the patterns has the air permeability effect, the anti-static effect and the radiation-resistant effect. The bamboo charcoal fiber shell fabric with the fabric provided with the patterns forms the patterns through changes of the interweaving twill-weave structure of the fabric, no dyeing is needed after the interweaving is finished, meanwhile, the warp yarns are the yarns added with the twist yarns, and therefore the fabric is stiff.

Owner:JIANGYIN CHUNLAN TEXTILE

Velvet fabric with high fullness of shade

InactiveCN104783367AUniform tensionUniform ductilitySynthetic resin layered productsClothingsFiberYarn

The invention relates to velvet fabric with high fullness of shade. The velvet fabric with high fullness of shade comprises velvet cloth (1), a sponge layer (2) is arranged under the velvet cloth (1), an anti-static layer (3) is arranged under the sponge layer (2) and made of core-spun yarn fibers, the fibers include yarns (3.1) and metal wires (3.2), the metal wires (3.2) are wound on the yarns (3.1), and a base layer (4) is arranged under the anti-static layer (3). The base layer is made of woven fabric comprises a base cloth layer, the base cloth layer is provided with a first surface and a second surface, at least one of the first and second surfaces of the base cloth layer is provided with a waterproof coating, and the base cloth layer is of a double-weft structure. The velvet fabric is graceful in luster, looks luxury, and is firm, durable, not prone to deformation, high in elasticity, breathable and high in fullness of shade, and can absorb humidity.

Owner:JIANGSU HONGLIU BEDSHEET LIMITED

Velvet fabrics with strong comfort level

InactiveCN104401052AReasonable structural designImprove breathabilityWeft knittingClothingsFiberYarn

The invention relates to a velvet fabrics with strong comfort level, which comprises velvet (1), a sponge layer (2) is arranged below the velvet (1), an antistatic layer (3) is arranged below the sponge layer (2), the antistatic layer (3) is made by corn silk fiber, the corn silk fiber comprises yarn (3.1) and metal wire (3.2), the metal wire (3.2) is wound on the yarn (3.1), and a base layer (4) is arranged below the antistatic layer (3). The base layer is made by fabric, the fabric is formed by a first yarn and a second yarn, the first yarn and the second yarn form a loop along a latitude direction of the fabric, and alternately and mutually interloopd along a vertical direction step by step to form the fabric with a weft knitting structure, protruding strips are arranged at right side of the fabric, and the protruding strips are knitted by the first yarn or the second yarn. The velvet fabrics has the advantages of elegant colored light, luxuriant design, firmness and wear resistance, difficult deformation, elasticity, moisture absorption and breathability. The employed fabric has the advantages of reasonable structure design, good permeability, strong stereo perception, strong comfort level and good hand feeling.

Owner:JIANGYIN HENGDA VEHICLES FITTING

Velvet shell fabric with good use performance

The invention relates to velvet shell fabric with good use performance. The velvet shell fabric comprises velvet cloth (1). A sponge layer (2) is arranged under the velvet cloth (1), an anti-static layer (3) is arranged under the sponge layer (2) and made of core-spun yarn fibers comprising yarns (3.1) and metal wires (3.2) wound around the yarns (3.1), and a base layer (4) is arranged under the anti-static layer (3). The base layer is made of textile fabric, warps and wefts of the textile fabric are made of wool fibers and coconut fibers respectively, the diameter of the wool fibers is 9 micrometers, the diameter of the coconut fibers is 10 micrometers, the warp density of the textile fabric is 26.6 pieces / cm, and the weft density of the textile fabric is 31.3 pieces / cm. The velvet shell fabric is elegant in color light, luxurious, gorgeous, firm, wearproof, not prone to deformation, good in elasticity, capable of absorbing moisture and breathable. The textile fabric adopted in the velvet shell fabric is reasonable in structure and good in use performance.

Owner:江阴市华凯针织制衣有限公司

Layered velvet fabric

The invention relates to a layered velvet fabric. The layered velvet fabric comprises velvet cloth (1), a spongy layer (2) is arranged under the velvet cloth (1), an anti-static layer (3) is disposed under the spongy layer (2), the anti-static layer (3) is made of core spun silk fibers, the fibers comprise yarns (3.1) and metal silks (3.2), the metal silks (3.2) wind the yarns (3.1), and a base layer (4) is disposed under the anti-static layer (3). The base layer is made of woven fabrics, a plurality of three-dimensional stripes are disposed on surfaces of the woven fabrics, the three-dimensional stripes are horizontally arranged at equal intervals, cross sections of the three-dimensional stripes are in L shape, each last three-dimensional stripe is joint with next adjacent three-dimensional stripe, each joint position is located at the bottom of last three-dimensional stripe to be fixed on the woven fabrics by threads, a plurality of connecting points are disposed on back sides of the three-dimensional stripes, and the connecting points are connected with the woven fabrics. The layered velvet fabric is elegant in colored light, magnificent and noble, firm and resistant to abrasion, not prone to deformation, fully elastic, capable of absorbing moisture and breathable. Layering of the fabric is enhanced through the three-dimensional stripes with the connecting points.

Owner:JIANGYIN CHENGXIN SPECIAL PRINTING

Mixed fabric with good heat preservation effect

InactiveCN104786573ASufficient air contentStop the spreadCellulosic plastic layered productsMetal layered productsEngineeringMetal

The invention relates to a mixed fabric with a good heat preservation effect. The mixed fabric comprises a pure cotton fabric (1), wherein a bamboo carbon fiber layer (2) is arranged under the pure cotton fabric (1); an anti-static layer (3) is further arranged under the bamboo carbon fiber layer (2) and made from core-spun silk fiber; the core-spun silk fiber comprises yarns (3.1) and metal wires (3.2); the metal wires (3.2) wind the yarns (3.1); the bottom of the anti-static layer (3) is coated with a layer of blended cloth (4); the blended cloth (4) is formed by blending soybean fiber and pure cotton fiber; a base layer (5) is compounded under the blended cloth (4); the base layer is made from a textile fabric, the textile fabric is formed by interweaving warp yarns and weft yarns, the warp yarns and the weft yarns adopt hollow structures, and a through hole is formed in the center of each of the warp yarns and the weft yarns along an axis. The mixed fabric is unlikely to shrink and wrinkle and good in heat preservation effect.

Owner:JIANGYIN CHUNLAN TEXTILE

Mixed fabric with uniform textile thickness

The invention relates to a mixed fabric with uniform textile thickness. The mixed fabric comprises a pure cotton fabric (1), wherein a bamboo carbon fiber layer (2) is arranged below the pure cotton fabric (1); an antistatic layer (3) is further arranged below the bamboo carbon fiber layer (2), and is made from core-spun yarn fibers; each core-spun yarn fiber comprises a yarn (3.1) and a metal wire (3.2); the metal wires (3.2) are wound on the yarns (3.1); the bottom of the antistatic layer (3) is covered with a layer of blended fabric (4) which is formed by blending soybean fibers and pure cotton fibers; a layer of substrate (5) is compounded below the blended fabric (4), and is formed by a textile; the textile is a felt textile, and the felt textile comprises a cloth layer and a wool layer, which are fixedly connected; the wool layer is a reticular textile consisting of crisscross wool filaments. The mixed fabric is unlikely to shrink and crease, and is uniform in textile thickness.

Owner:江阴市华凯针织制衣有限公司

Blended fabric

The invention relates to a mixed fabric. It is characterized in that: it includes pure cotton fabric, a layer of bamboo charcoal fiber layer is arranged under the pure cotton fabric, and an antistatic layer is arranged under the bamboo charcoal fiber layer, the antistatic layer is made of core-spun silk fiber, the Fibers include yarns and wires wound around the yarns. Compared with the prior art, the beneficial effect of the present invention is that the yarn and the metal wire in the mixed fabric form the cored wire to form an antistatic layer, so that the fabric has special rigidity, variable bending, and strong three-dimensional effect , can form various wrinkle effects, not easy to shrink, not easy to wrinkle, shiny metallic luster, delicate hand feeling, anti-static, anti-radiation effect.

Owner:XINCHANG COUNTY ZHUOYUAN TEXTILE CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com