Bamboo charcoal fiber shell fabric with fabric provided with patterns

A technology of bamboo charcoal fiber and fabric, which is applied in fabrics, textiles, textiles, and papermaking, and can solve problems such as poor three-dimensional effect, single shape, and fabrics without patterns

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

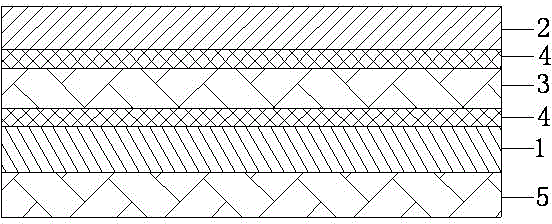

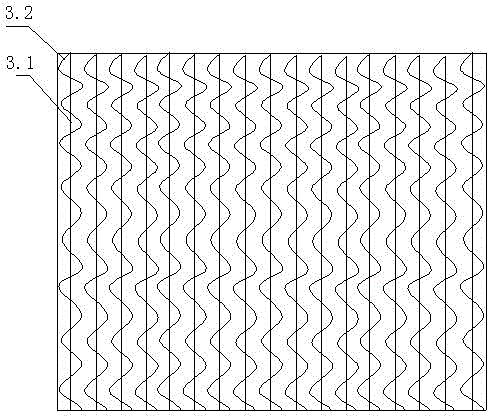

[0013] see figure 1 and figure 2 , the present invention relates to a kind of bamboo charcoal fiber fabric with pattern, it comprises bamboo charcoal fiber 1, described bamboo charcoal fiber 1 is covered with a layer of non-woven fabric 2, and the bottom is covered with a layer of base layer 5, and described non-woven fabric 2 and Also be provided with antistatic layer 3 between bamboo charcoal fiber 1, this antistatic layer 3 is made of core-spun silk fiber, and this core-spun silk fiber comprises yarn 3.1 and metal wire 3.2, and described metal wire 3.2 is wound on yarn 3.1 Above, the glue layer 4 is used to bond between the bamboo charcoal fiber 1 and the antistatic layer 3 and between the antistatic layer 3 and the non-woven fabric 2 .

[0014] Bamboo charcoal fiber and non-woven fabrics in this kind of patterned bamboo charcoal fiber fabric have better air permeability, yarn 3.1 and metal wire 3.2 form an antistatic layer after forming a cored yarn, which makes the fabr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com